Researchers from the Institute of Engineering Thermophysics at the Chinese Academy of Sciences, guided by esteemed professors Ting Zhang and Haisheng Chen, have introduced a groundbreaking approach to the fabrication of flexible fiber sensors known as thermally drawn flexible fiber sensors (TDFSs). Their comprehensive review highlights the principles, material selection criteria, and advancements in this innovative thermal drawing process. The significance of TDFSs in a variety of applications is underscored by their ability to detect a range of stimuli, including temperature, pressure, strain, chemicals, light, and biological signals, solidifying their position as essential components in wearable and implantable technologies.

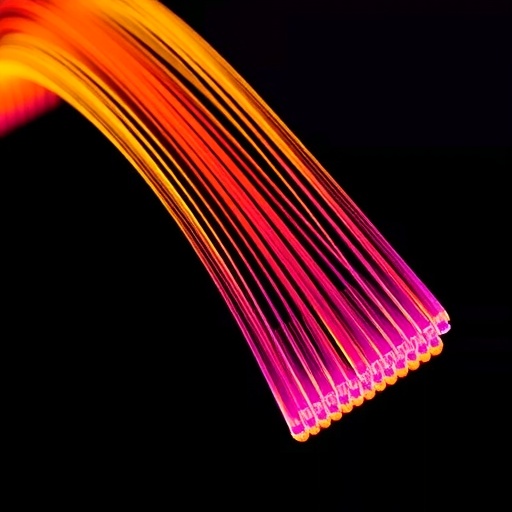

The thermal drawing process represents a revolutionary method for manufacturing fiber sensors at an unprecedented scale. This method allows the production of kilometer-long fibers with integrated functionalities, effectively bypassing the conventional hurdles faced by traditional fiber fabrication methods. Researchers are optimistic that these advancements will pave the way for rapid and automated production systems that can meet the growing demand for flexible and multifunctional sensing devices that are key to the future of smart technology.

In addition to scalability, TDFSs offer remarkable multifunctionality. These sensors have been specifically designed to monitor various environmental and biological signals. In wearable technology, this versatility opens up new avenues for health monitoring devices capable of tracking vital signs such as heart rate, body temperature, and motion with high accuracy and comfort. Furthermore, their potential for integration into smart textiles highlights their adaptability across a broad spectrum of industries, from healthcare to consumer electronics.

The material selection criteria for TDFSs is critical to their effectiveness, requiring a meticulous balance between thermal and mechanical properties. Researchers emphasize the importance of correlating factors such as glass transition temperature and thermal expansion coefficients to ensure optimal performance and structural integrity. The complexities of creating composite fibers that maintain these properties while incorporating various functionalities underscore the sophistication of the thermal drawing process.

Through this process known as preform-to-fiber technique, researchers heat macroscopic preforms and draw them into flexible fibers that contain embedded functional materials. This approach enables the incorporation of diverse microstructures, which enhances the sensing capabilities of the fibers. Types of sensors developed through this technique range widely, encompassing resistive, capacitive, piezoelectric, triboelectric, photoelectric, and thermoelectric principles, all relevant to specific applications such as temperature monitoring, acoustic sensing, mechanical strain detection, chemical analysis, biological sensing, and optoelectronics.

The field of wearable health monitoring is set to experience a significant transformation as TDFSs woven into fabrics offer novel solutions for various applications. The integration of these sensors into clothing not only allows for continuous monitoring of physiological parameters but also ensures user comfort and mobility. By providing real-time data tracking, TDFSs could influence how we manage health and wellness, leading to more personalized and preventive approaches in healthcare.

Moreover, the potential application of TDFSs extends beyond wearable devices to include implantable neural probes. These flexible, biocompatible fiber sensors are designed to facilitate long-term neural recording and stimulation while minimizing damage to surrounding tissues. Such capabilities are a monumental advancement in neuroscience, providing researchers and clinicians new tools to explore brain function and tackle neurological disorders with unprecedented precision.

Another major breakthrough associated with TDFSs is their capability for distributed sensing. These fibers can perform spatially resolved sensing, making them valuable in various emerging fields, including environmental monitoring, robotics, and smart systems. By distributing sensor capabilities across multiple fibers, complex networks can be established, offering enhanced data collection and analysis that could redefine how environmental changes are monitored and responded to.

Despite the promising advancements, the review presents a critical look at the challenges that still hinder the realization of TDFSs in commercial settings. Issues such as material compatibility, optimal structural design, and long-lasting stability must be carefully addressed. As the demand for multifunctional sensors continues to rise, ongoing research will need to focus on integrating multiple sensing functions into a single fiber while improving durability and expanding the materials used in production.

The future of thermally drawn fiber sensors appears bright, with immense potential waiting to be unlocked. As the field evolves, future studies may concentrate on enhancing the operational capabilities of these sensors and exploring new materials that broaden their applicability across various domains. The continuous improvement in manufacturing techniques and material science could herald a new era where the integration of sophisticated sensors becomes commonplace in daily life.

With the rapid growth of the wearable technology and smart textiles markets, the contributions of Prof. Ting Zhang and Prof. Haisheng Chen’s team are poised to make substantial impacts. Their efforts in advancing the field of thermally drawn fiber sensors can potentially revolutionize how we interact with technology, healthcare, and the environment. As innovations in this area continue to emerge, adjustments in regulatory frameworks and industry standards will be necessary to support the proliferation of such advanced sensing devices.

The implications of TDFSs reach far beyond simplicity in design and scalability. They embody a vision for a future where technology transcends the limitations of traditional sensors, enhancing our ability to gather data seamlessly and interact with our environments in more meaningful ways. The work being done at the Chinese Academy of Sciences epitomizes the cutting-edge research that will likely lead to new breakthroughs in the next generation of sensor technologies.

This review of thermally drawn flexible fiber sensors reveals not only the current state of the technology but also the immense possibilities that lie ahead. As researchers worldwide continue to explore and innovate, the integration of TDFSs into practical applications will continue to unfold, reshaping the landscape of sensor technology and smart systems as we know them today.

Subject of Research: Thermally Drawn Flexible Fiber Sensors

Article Title: Thermally Drawn Flexible Fiber Sensors: Principles, Materials, Structures, and Applications

News Publication Date: 18-Jul-2025

Web References: DOI

References: None provided

Image Credits: ZhaoLun Zhang, Yuchang Xue, Pengyu Zhang, Xiao Yang, Xishun Wang, Chunyang Wang, Haisheng Chen, Xinghua Zheng, Xin Yin, Ting Zhang

Keywords: Applied sciences and engineering, Technology, Sensors

Tags: automated production systems for sensorsbiological signal detectionenvironmental signal monitoringflexible sensor materialsinnovative thermal drawing processmultifunctional sensing devicesscalable fiber sensor manufacturingsmart technology advancementsstrain and pressure detectionTDFS applications in wearable technologytemperature and chemical sensingthermally drawn flexible fiber sensors