In a groundbreaking development poised to reshape the future of electrocatalytic hydrogen production, researchers from Nanjing University in China and Washington State University in the USA have unveiled a novel approach for constructing high-performance electrocatalysts. Their innovative strategy centers on engineering a highly ordered, three-dimensional mesoporous carbon framework embedded with nickel single atoms, achieved through a pioneering “superlattice blotting” method. This technique addresses longstanding challenges in catalyst design related to stability, mass transport, and active site efficiency, heralding significant advances in sustainable energy technology.

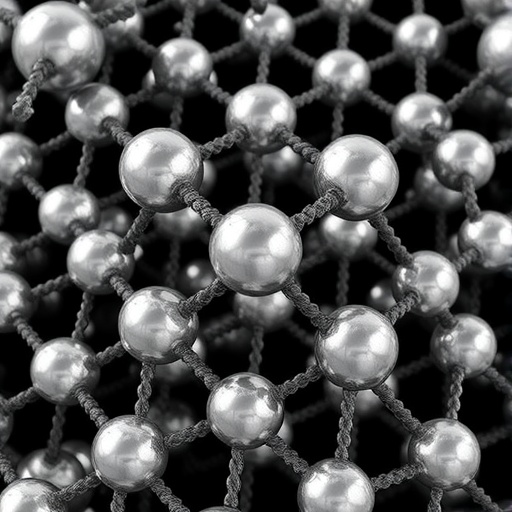

The core challenge in electrocatalysis for hydrogen production lies in optimizing the interplay between catalyst activity, durability, and mass transport at the gas-liquid-solid interface. Porous materials, especially carbon frameworks, have long been leveraged for their vast surface areas and interconnected channels, which facilitate catalytic sites’ accessibility. However, disordered pore architectures often induce irregular gas flow and electrolyte transport, resulting in uneven reaction kinetics, bubble accumulation, and structural degradation over extended operation. This latest study overcomes these barriers by carefully orchestrating pore order and surface chemistry at the nanoscale.

Central to their approach was the application of finite element simulation to rigorously analyze gas pressure distributions in different porous environments. The team found that ordered mesoporous structures facilitate uniform gas flow and consistent impact stress on pore walls, in contrast to disordered networks where gas velocity varied widely between large and small pores. These pressure disparities were found to disrupt the stability of the thin electrolyte film at the catalytic interface, reducing effective contact area and catalytic activity. By promoting a stable, ultra-thin liquid membrane along hydrophilic pore surfaces, the ordered framework maximizes gas-liquid-solid equilibrium and mass transfer kinetics, a vital advancement for efficient hydrogen evolution reactions.

Building on this theoretical insight, the researchers devised the superlattice blotting synthesis to translate simulations into functional materials. They employed the self-assembly of nickel nanocrystals into superlattices, effectively confining oxidative reactions and enhancing thermal stability without compromising nanoscale morphology or size. Subsequent ligand carbonization at moderate temperatures preserved the superlattice’s porous architecture, while acid etching exposed a robust three-dimensional mesoporous carbon skeleton enriched with nickel ions. A final high-temperature graphitization step incorporated heteroatom doping, such as nitrogen, sulfur, and phosphorus, fine-tuning electronic properties and overall conductivity.

Advanced characterization techniques including spherical aberration electron microscopy and extended X-ray absorption fine structure spectroscopy confirmed the successful dispersion of isolated nickel single atoms within the mesoporous carbon matrix. The nickel centers were coordinated distinctly in two catalyst variants: Ni atoms bonded to two nitrogens and two sulfurs (Ni-N₂S₂) and Ni atoms coordinated with three nitrogens and one phosphorus atom (Ni-N₃P). This precise heteroatomic coordination was shown to play a critical role in modulating the electronic environment of the metal centers and optimizing catalytic function.

Evaluating electrocatalytic performance revealed remarkable results. The Ni-N₂S₂ catalyst demonstrated superior oxygen evolution reaction (OER) activity, achieving an impressively low overpotential of 239 millivolts at 20 milliamps per square centimeter, significantly outperforming commercial ruthenium oxide catalysts under the same conditions. Conversely, the Ni-N₃P configuration excelled in the hydrogen evolution reaction (HER), requiring a mere 90 millivolts overpotential to reach 10 milliamps per square centimeter, indicative of rapid kinetics consistent with a Heyrovsky-type mechanism. These values rank among the best reported for nickel-based single-atom catalysts.

Further leveraging these synergistic catalysts, the team assembled a two-electrode system pairing the Ni-N₂S₂ catalyst as the anode with the Ni-N₃P catalyst as the cathode, achieving full water electrolysis at a low overall cell potential of 1.59 volts for 10 milliamps per square centimeter. This system maintained stable operation for over 100 hours, demonstrating exceptional durability without compromise in catalytic current, a key criterion for practical renewable energy applications. The ordered porous support is critical to this performance, facilitating efficient gas release and electrolyte circulation, thereby maintaining an active three-phase boundary.

This study marks a major leap forward in catalysis design by bridging theoretical models, innovative synthesis routes, and precise atomic engineering. The integration of finite element-guided superlattice imprinting with heteroatom-coordinated single-atom catalysts offers a blueprint for developing durable, highly active electrocatalysts that harness the full potential of nanoconfinement and optimized microenvironments. Moreover, the formation of stable ultra-thin liquid membranes along hydrophilic ordered pore walls highlights a fundamentally new mechanistic understanding of three-phase electrochemical interfaces.

The implications extend beyond water splitting, as the principles and methodologies demonstrated here can be adapted to a wide range of electrocatalytic transformations, including CO₂ reduction, nitrogen fixation, and fuel cell reactions. The high thermal stability and electronic tunability arising from the superlattice-derived ordered mesoporous skeleton open pathways for tailored catalyst architectures with expanded functionality. This cross-disciplinary approach combining computational modeling, nanoengineering, and advanced characterization sets a new standard for catalyst innovation.

Looking forward, the team’s framework for constructing high-density nickel single atoms anchored inside tailored mesoporous hosts could drive the next generation of clean energy devices. Coupled with ongoing developments in scalable manufacturing and renewable feedstocks, these fundamental breakthroughs promise to accelerate the global transition toward green hydrogen production and sustainable chemical synthesis. With continuing research, the underlying concepts of controlled three-phase equilibrium and precise heteroatom coordination are poised to become ubiquitous tools in the design of future electrocatalytic systems.

This pioneering research not only amplifies the functional capabilities of carbon-based catalysts but also exemplifies the power of integrating computational design with experimental realization. Such synergy enables the creation of complex yet finely controlled materials at the atomic scale, bridging the gap between fundamental science and practical technologies. As the urgency of climate change intensifies, innovations like these are critical to unlocking the potential of renewable energy and catalysis for a sustainable future.

The study was published in CCS Chemistry, the flagship journal of the Chinese Chemical Society, reflecting the global importance and interdisciplinary nature of the work. With the no-cost open-access policy of the journal, these insights and technological advances are now accessible to the worldwide scientific community, fostering collaboration and rapid progress in electrocatalysis and energy materials science. The authors declare no conflicts of interest, emphasizing the academic rigor and integrity underpinning these contributions.

In summary, by leveraging finite element simulations to inform the design of ordered mesoporous carbon skeletons and deploying a novel superlattice blotting synthesis, this work delivers a blueprint for fabricating stable, high-performance nickel single-atom electrocatalysts. The stable gas–liquid–solid interface supported by an ultra-thin liquid film, combined with heteroatom-tuned single-atom sites, achieves unrivaled catalytic efficiency and durability in water splitting. These advances bring us closer to scalable, economically viable hydrogen production, a cornerstone in the quest for sustainable energy systems worldwide.

Subject of Research: Not applicable

Article Title: A Superlattice Imprinting Method to Construct High Ni Single Atoms Inside Ordered Mesoporous Carbon for Efficient Electrocatalysis

News Publication Date: 10-Sep-2025

Web References:

https://www.chinesechemsoc.org/journal/ccschem

http://dx.doi.org/10.31635/ccschem.025.202505938

References:

Yuanyuan Wang, Wenlei Zhu, Yuehe Lin et al., CCS Chemistry, DOI: 10.31635/ccschem.025.202505938

Image Credits: CCS Chemistry

Keywords

Superlattices, ordered mesoporous carbon, single-atom catalysis, nickel single atoms, electrocatalysis, hydrogen evolution reaction, oxygen evolution reaction, finite element simulation, heteroatom doping, superlattice blotting, energy conversion, water splitting

Tags: advanced electrocatalyst design methodscatalyst stability and efficiencyfinite element simulation in catalysisgas-liquid-solid interface optimizationhighly ordered mesoporous carbonhydrogen production electrocatalysismass transport in porous structuresnanoscale pore architecture engineeringnickel single atom electrocatalystsporous carbon materials for catalysissuperlattice blotting techniquesustainable energy technology