In a transformative step for the field of soft robotics and wearable technology, researchers have unveiled an innovative approach to engineering flexible fiber pumps, leveraging the precise winding of printed electrode patterns on soft substrates. This breakthrough—detailed in a recent publication by Qi, Jin, Wang, and colleagues—heralds a new era of customizable soft actuators that promise to dramatically extend the capabilities of soft machines and wearable devices.

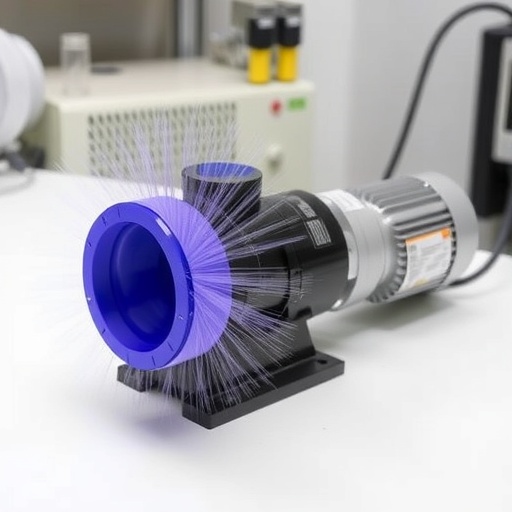

At the heart of this innovation is the intricate fabrication method that allows printed electrode patterns to be helically wound onto soft fibers, crafting pumps with exquisite control over fluid movement within elastomeric channels. Unlike traditional rigid pumps, these soft fiber pumps are lightweight, stretchable, and conform to curved surfaces, making them ideal components for next-generation flexible electronics and biomedical devices.

The methodology relies on a synergy between advanced printing techniques, material science, and mechanical engineering. By depositing conductive inks with high precision onto compliant substrates, the team achieves electrode patterns that can endure bending and twisting without loss of electrical integrity. These electrodes are then patterned in helical or spiral geometries around fiber cores, creating a dynamic interface that can induce fluid flow when electrically actuated.

.adsslot_89jrYNICeo{width:728px !important;height:90px !important;}

@media(max-width:1199px){ .adsslot_89jrYNICeo{width:468px !important;height:60px !important;}

}

@media(max-width:767px){ .adsslot_89jrYNICeo{width:320px !important;height:50px !important;}

}

ADVERTISEMENT

This electrode winding strategy not only optimizes the pump’s actuation efficiency but also offers an unprecedented level of customization in pump performance. Parameters such as pumping pressure, flow rate, and actuation amplitude can be finely tuned simply by adjusting the winding angle, spacing, or pattern geometry of the printed electrodes. Consequently, designers can tailor pumps to meet specific application requirements across a wide spectrum of fields.

A remarkable aspect of this research is the adaptability of the fabrication process, which can integrate with scalable printing technologies. By combining digital printing methods with automated winding systems, the production of these soft fiber pumps moves closer to commercialization, offering a path toward cost-effective manufacturing of personalized soft actuators at scale.

Moreover, the paper elucidates the electrohydrodynamic principles driving the fluid movement within these soft pumps. By applying alternating electric fields across the printed electrodes, the ion migration and electro-osmotic flows within the enclosed channels enable controlled fluid displacement. This mechanistic understanding underpins the design ethos, allowing the researchers to optimize electrode layouts for maximal pumping efficiency.

Mechanical characterization of the pumps demonstrates their robustness under cyclic bending, stretching, and twisting. These tests validate the endurance of the printed electrodes and the mechanical integrity of the soft fiber structure. The researchers report sustained performance over thousands of actuation cycles, a critical benchmark for practical deployment in wearable or implantable devices.

One particularly captivating application highlighted is the integration of these soft pumps into textile systems, creating smart garments capable of regulated fluid delivery. Such technology opens avenues for responsive cooling garments, drug delivery systems, and wearable sensors that can dynamically interact with the wearer’s physiology, enhancing comfort and health monitoring.

In biomedical contexts, the soft fiber pumps’ biocompatibility and conformability shine. They offer potential as implantable devices for controlled drug infusion, lymphatic fluid manipulation, or blood flow assistance without the adverse effects associated with rigid mechanical components. This compatibility positions them as promising candidates for minimally invasive therapeutic technologies.

Further, the researchers explore the modulation of the pump’s performance through external stimuli beyond electrical actuation. They discuss possibilities such as integrating responsive materials that can alter the electrode patterns or channel morphology under thermal or optical triggers, enabling multifunctional soft devices with complex, programmable behavior.

The versatility of the winding technique also extends to multi-functional architectures. By varying electrode materials and incorporating multi-layered winding schemes, soft fiber pumps could simultaneously serve as sensors and actuators, forming closed-loop feedback systems crucial for autonomous soft robotic functions.

Importantly, the study contributes a comprehensive computational model that simulates the interplay between electrode geometry, electrical input, and fluid dynamics. This predictive tool helps design optimization and accelerates the development cycle by reducing reliance on costly experimental iterations.

From an environmental perspective, the materials employed are chosen for their sustainability and recyclability. Printable conductive inks based on carbon or silver nanomaterials used in the electrodes ensure both high performance and reduced ecological impact, aligning the innovation with growing demands for green electronics.

The implications of this work ripple beyond soft fiber pumps, influencing the broader domain of flexible electronics and smart materials. The ability to engineer 3D electrode patterns on soft substrates is a foundational advance that could impact energy harvesting, flexible displays, and responsive surfaces.

Ultimately, this research reflects the interdisciplinary collaboration between materials scientists, engineers, and designers. It underscores how marrying precision fabrication with deep theoretical insight can unlock unprecedented functionalities in the rapidly evolving ecosystem of soft technologies.

With the foundational framework established, future directions are poised toward miniaturization and integration. Embedding soft fiber pumps with wireless power sources, sensors, and control circuits could yield fully autonomous systems capable of performing complex tasks in challenging environments, from human-machine interfaces to environmental monitoring.

As interest in wearable health devices and soft robotics surges, the customizable soft fiber pumps with wound printed electrodes emerge as a cornerstone technology. Their blend of flexibility, precision, and adaptability encapsulates the next generation of intelligent, human-centric machines designed to blend seamlessly with biological tissue and natural motion.

This pioneering work not only charts new frontiers in material patterning and soft actuator design but also ignites imagination across disciplines, promising to reshape how machines interact with the world and its inhabitants in the coming decades.

Subject of Research: Development and customization of soft fiber pumps through winding printed electrode patterns for enhanced fluid actuation in flexible electronics and soft robotics.

Article Title: Winding printed electrode patterns to customize soft fiber pumps.

Article References:

Qi, Y., Jin, T., Wang, J. et al. Winding printed electrode patterns to customize soft fiber pumps. npj Flex Electron 9, 79 (2025). https://doi.org/10.1038/s41528-025-00461-0

Image Credits: AI Generated

Tags: advanced printing techniques in engineeringbiomedical device applicationsconductive inks for soft actuatorscustom soft fiber pumpscustomizable soft actuatorselastomeric channel fluid movementflexible electronics designhelical electrode geometrieslightweight stretchable pumpssoft robotics innovationswearable technology advancementswinding electrode patterns