In a groundbreaking advance that could reshape the future of carbon capture and utilization, researchers at the Gwangju Institute of Science and Technology (GIST) in South Korea have unveiled a remarkable electrochemical method to convert carbon dioxide (CO₂) into allyl alcohol, a high-value, multi-carbon liquid chemical. This novel approach not only drastically improves conversion efficiency but also establishes new global performance benchmarks, signaling a significant step forward in the race toward carbon neutrality and sustainable chemical manufacturing.

As global CO₂ emissions reach unprecedented levels amid the accelerating challenges of climate change, the urgency for effective technologies to recycle this greenhouse gas intensifies. Among the various strategies to valorize CO₂, transforming it directly into energy-dense, valuable chemicals like alcohols has long been viewed as a promising avenue. Yet, achieving efficient, selective conversion to liquid C₃+ (three or more carbon atoms) compounds remains elusive due to the inherent complexities in catalysis, reaction intermediates stability, and energy efficiency.

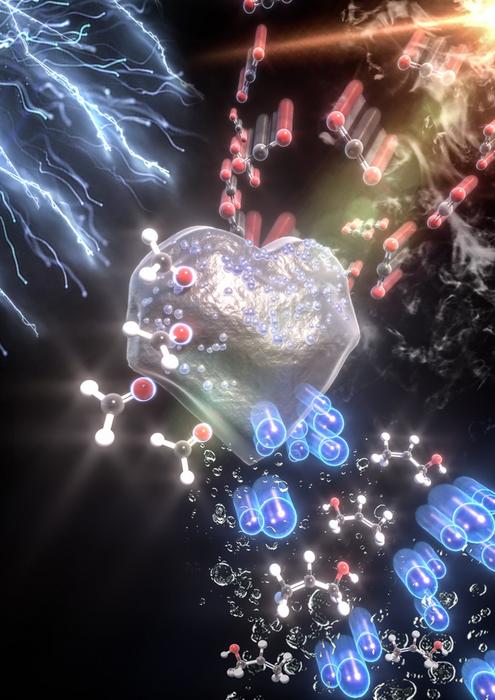

The team, led by Professor Jaeyoung Lee along with Drs. Minjun Choi and Sooan Bae, has developed a phosphorus-rich copper catalyst system integrated within a membrane-electrode assembly, which includes a complementary nickel–iron oxidation catalyst. This configuration enables selective formaldehyde condensation reactions during the electrochemical reduction of CO₂, culminating in a highly efficient production of allyl alcohol. Impressively, the system attains a Faraday efficiency of 66.9%, an approximately fourfold improvement over previous technologies, which have struggled to surpass 15%.

.adsslot_qwHPLc3aXD{width:728px !important;height:90px !important;}

@media(max-width:1199px){ .adsslot_qwHPLc3aXD{width:468px !important;height:60px !important;}

}

@media(max-width:767px){ .adsslot_qwHPLc3aXD{width:320px !important;height:50px !important;}

}

ADVERTISEMENT

One of the principal technical challenges addressed by the researchers is the facilitation of C–C bond formation during CO₂ conversion. Conventional approaches predominantly operate via carbon monoxide intermediates, which complicate the synthesis of higher molecular weight products. In contrast, the GIST team’s method uniquely navigates a novel reaction mechanism, promoting the formation of C–C bonds during the transformation of formate to formaldehyde intermediates. This shift in pathway not only enhances selectivity and yield but also stabilizes reactive species that typically prove transient and elusive in electrocatalytic environments.

Accomplishing such a leap in selectivity requires a catalyst with exceptional surface properties and chemical affinity. By integrating copper phosphide (CuP₂) into the electrode architecture, the catalyst exhibits a phosphorus-rich surface that effectively stabilizes reaction intermediates necessary for allyl alcohol synthesis. The synergy between the copper-phosphorus active sites and the nickel–iron layer optimizes electron transfer, minimizes side reactions, and suppresses undesired byproducts, thereby concentrating the electrochemical energy towards the target molecule.

Beyond efficiency, the reported technology also sets new records in current density and production rates. The electrochemical system operates at a partial current density of 735.4 mA cm⁻² and produces allyl alcohol at an unprecedented rate of 1643 μmol cm⁻² h⁻¹. These metrics highlight the method’s scalability potential, making it a promising candidate for industrial deployment. The ability to sustain high current densities while maintaining selectivity and production output is critical for transitioning from laboratory prototypes to commercial-scale CO₂ valorization technologies.

Allyl alcohol itself is an industrially vital compound with wide-ranging applications spanning the manufacture of plastics, adhesives, fragrances, and sterilizers. Currently, its production relies heavily on petroleum-based processes that are energy intensive and environmentally taxing. The GIST team’s electrochemical approach not only offers a sustainable alternative by leveraging waste CO₂ as a feedstock but also could catalyze a paradigm shift in chemical manufacturing, fostering carbon-neutral supply chains and reducing reliance on fossil resources.

This innovative CO₂-to-allyl alcohol technology further distinguishes itself through its liquid product output. Unlike gaseous fuels or products, liquids like allyl alcohol are inherently easier to store, transport, and integrate into existing industrial infrastructures. This practicality enhances the commercial appeal of the technology and aligns closely with broader goals to implement circular carbon economies where captured CO₂ is seamlessly converted into market-ready chemicals.

The researchers underscore that the development is not merely a technical achievement but also a foundational step toward transformative industrial applications. Professor Lee emphasizes that this technology could create new business opportunities across traditionally high-emission sectors such as coal, petrochemicals, and steel, helping them meet tightening environmental regulations through scalable, science-driven carbon recycling.

While the results are promising, the team acknowledges that further work is needed to realize continuous-flow operation and integrate zero-gap membrane-electrode assemblies for industrial-scale production. Dr. Choi highlights the need to refine the system for durability and sustainability to pave the way for broad adoption. Ultimately, combining such advances could significantly reduce global dependency on fossil fuels, accelerating the transition toward a greener energy and chemical landscape.

The breakthrough reflects not only a sophisticated understanding of electrochemistry and catalysis but also innovative design at the material and systems level. By pushing beyond the traditional focus on single- or two-carbon products (C₁ and C₂), this research broadens the horizon for CO₂ valorization, emphasizing the generation of more complex, higher-value molecules that meet industrial demands while aligning with climate objectives.

Published in Nature Catalysis on May 22, 2025, this study represents a milestone in carbon dioxide electroreduction research, combining novel catalyst chemistry, innovative reaction pathways, and impressive electrochemical performance metrics. The work stands as a testament to interdisciplinary collaboration and visionary research underpinned by cutting-edge materials science and chemical engineering.

As the world grapples with environmental imperatives and energy transitions, such breakthroughs ignite optimism for sustainable technologies capable of closing the carbon loop. The GIST team’s achievement signals a new chapter in electrochemical CO₂ utilization, inspiring further exploration into catalysis and reactor engineering to unlock the full potential of carbon recycling for future generations.

Subject of Research:

Not applicable

Article Title:

Selective formaldehyde condensation on phosphorus-rich copper catalyst to produce liquid C3+ chemicals in electrocatalytic CO2 reduction

News Publication Date:

22-May-2025

Web References:

http://dx.doi.org/10.1038/s41929-025-01341-6

References:

DOI: 10.1038/s41929-025-01341-6

Image Credits:

Prof. Jaeyoung Lee

Keywords

Chemical engineering, Environmental management, Pollution, Natural resources conservation, Environmental engineering, Carbon compounds, Chemical compounds, Engineering, Applied sciences and engineering, Physical sciences

Tags: allyl alcohol productioncarbon capture and utilizationcarbon neutrality technologiesclimate change mitigation strategieselectrochemical conversion of CO₂energy-dense liquid chemicalshigh-value chemical feedstocksmembrane-electrode assembly in catalysisphosphorus-rich copper catalystsustainable chemical manufacturingtransforming greenhouse gases into chemicals