A groundbreaking advancement in textile science has emerged from researchers at Qingdao University, China, who have developed an innovative treatment method that significantly enhances the durability and multifunctional properties of lyocell fabric. Lyocell, a regenerated cellulose fiber acclaimed for its eco-friendly nature and intrinsic high strength, has historically faced a major limitation due to its proneness to fibrillation. This phenomenon, which leads to surface fibrils that cause pilling and degrade color vibrancy especially after laundering, has impeded the fiber’s broader applicability in various industries. The newly proposed approach promises to surmount these issues, potentially revolutionizing the way lyocell fabric is utilized across apparel, home textiles, and healthcare sectors.

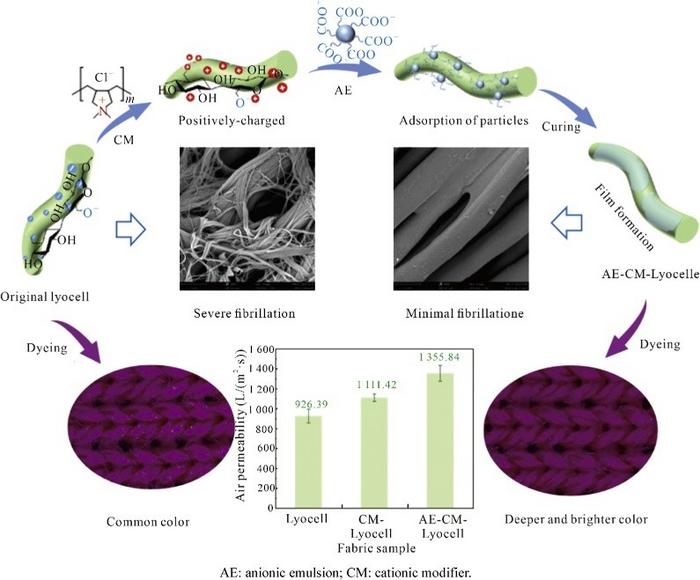

The study, recently published in the Journal of Bioresources and Bioproducts, meticulously details a novel protocol leveraging electrostatic adsorption and discontinuous membrane formation on the fiber surface. The core of this technology involves an initial treatment of lyocell fibers with a cationic modifier (CM). This step alters the surface charge characteristics, thereby enabling the subsequent application of anionic polyacrylic acid emulsions (AEs), which interact through electrostatic forces. The result is the formation of a discontinuous protective film encapsulating the fiber surface, a strategic barrier that inhibits water infiltration and reinforces cohesion between microfibrils under wet conditions.

Such an electrostatic assembly imparts exceptional anti-fibrillation capabilities to lyocell textiles. Experimental washing cycles reveal a significant reduction in the generation of fibrils, thereby suppressing the pilling and preserving the fabric’s smooth aesthetic. Unlike some traditional treatments that compromise the fabric’s hand feel or mechanical integrity, this method maintains the inherent strength and whiteness of the fibers. Remarkably, it also enhances several functional parameters, including a 46.4% increase in air permeability, which can be directly correlated with improved breathability—a highly sought-after characteristic in modern fashion and technical textiles.

Beyond durability and breathability enhancements, the treatment was found to markedly improve the dyeability of lyocell fabric. The anionic polyacrylic acid emulsion layer harmonizes with various dyes, resulting in richer coloration and elevated glossiness without introducing chemical harshness or toxicity. This multifaceted improvement addresses longstanding challenges in textile manufacturing, where eco-friendly fibers like lyocell often compete with synthetic alternatives boasting superior dye retention and luster. The newly introduced surface modification technique thus bridges a critical gap between sustainability and performance.

Abrasion tests conducted on the treated fabric further confirm its robustness. Both wet and dry rub resistance exceeded standard benchmarks, suggesting that treated lyocell textiles can withstand the mechanical stresses typical in everyday wear and home laundering. This property extends the usable life of garments and textile products, thereby reducing waste and contributing to the circular economy. Since sustainability remains at the forefront of consumer and regulatory demands, such innovations could catalyze a shift toward wider adoption of cellulose-based fibers in sectors hitherto dominated by petrochemical-derived fabrics.

Importantly, the researchers underscore the green credentials of the method itself. The treatment avoids harsh chemical agents and employs water-based emulsions, aligning with principles of green chemistry and minimal environmental impact. Optimization of treatment parameters—namely AE concentration, curing temperature, and curing duration—proved crucial in achieving balanced enhancements without over-processing the delicate lyocell fibers. This meticulous calibration protects the fiber’s inherent biodegradability and maintains its soft hand feel, critical attributes for market acceptance.

The implications of this research extend far beyond mere textile finishing. By demonstrating that electrostatic adsorption can effectively create protective, multifunctional membrane layers on natural fibers, this approach lays groundwork for next-generation functional textiles. Potential applications include antimicrobial finishes, UV protection coatings, and smart textile integrations, all leveraging the same fundamental principles. The ability to tune the surface chemistry of cellulose fibers opens myriad possibilities for bespoke fabric properties tailored to specific end-use requirements.

From an industrial perspective, scalability and cost-effectiveness are pivotal for technology adoption. The researchers report that their method is compatible with existing textile processing infrastructures, requiring only modest adjustments to conventional treatment lines. The aqueous nature of the process also reduces dependency on solvents, cutting operational expenses and limiting worker exposure to harmful chemicals. This positions the technology as a viable candidate for commercial uptake in textile manufacturing hubs, promising not only enhanced product quality but also improved workplace safety and environmental sustainability.

Furthermore, the enhanced durability and multifunctionality of treated lyocell fabric herald opportunities in healthcare textiles, an emerging field where fabric hygiene, comfort, and longevity are of paramount importance. Treated lyocell could be developed into superior wound dressings, surgical gowns, and bedding materials that combine high breathability with resistance to microbial colonization and mechanical degradation. This could lead to better patient outcomes and reduce hospital-associated textile waste.

In a broader context, this study exemplifies the power of interdisciplinary collaboration between textile science, polymer chemistry, and material engineering. It highlights how fundamental knowledge of electrostatic interactions and polymer film formation can be ingeniously applied to practical challenges faced by the textile industry. The research sets a precedent for future innovations aimed at reconciling ecological responsibility with product performance, a crucial endeavor as sustainable development goals become embedded across industrial sectors.

In summary, the novel treatment method developed by Qingdao University researchers represents a significant leap forward in lyocell fabric technology. Through electrostatic adsorption and the formation of a discontinuous polymer membrane, they have substantially mitigated the chronic issue of fibrillation while simultaneously boosting air permeability, dyeability, abrasion resistance, and glossiness. This multifunctional enhancement strategy unlocks new commercial avenues for lyocell, supporting the broader transition toward sustainable, high-performance textiles that meet contemporary consumer and environmental expectations.

Continued research and development will focus on fine-tuning the process for various fabric types and scales of production, alongside exploring additional functional upgrades such as antimicrobial effects and moisture management. With global textile industries under mounting pressure to adopt sustainable practices without sacrificing quality, innovations like this offer compelling solutions that marry science with market needs, promising to redefine the future landscape of cellulose-based textiles.

Subject of Research: Not applicable

Article Title: Sustainable Anti-Fibrillation and Multifunction Enhancement of Lyocell Fabric via Electrostatic Adsorption and Discontinuous Membrane Formation

News Publication Date: 11-May-2025

Web References:

https://doi.org/10.1016/j.jobab.2025.05.003

https://www.sciencedirect.com/journal/journal-of-bioresources-and-bioproducts

References: 10.1016/j.jobab.2025.05.003

Image Credits: Shandong Key Laboratory of Medical and Health Textile Materials, College of Textiles & Clothing, Qingdao University, Qingdao, China

Keywords: Materials science, Technology, Agriculture, Engineering, Plant sciences, Biochemistry

Tags: advanced textile treatments for apparelanti-fibrillation treatment for lyocell fabriccellulose fiber technology breakthroughsdurability enhancement of lyocell fiberseco-friendly textile innovationselectrostatic adsorption in textile sciencelyocell fabric applications in healthcaremultifunctional properties of textile fibersnovel protocols in fabric treatmentpilling resistance in fabricssurface modification of textile fiberssustainable materials in home textiles