In a significant advancement for the field of microfluidics, a team of researchers led by Toyohashi University of Technology in Japan has successfully optimized a PDMS-based SlipChip device to enhance its sealing, slipping, and biocompatibility by employing low-viscosity silicone oils. This breakthrough is expected to pave the way for more reliable and sophisticated cellular experiments and drug testing applications, addressing longstanding challenges associated with device leakage, channel clogging, and cytotoxicity.

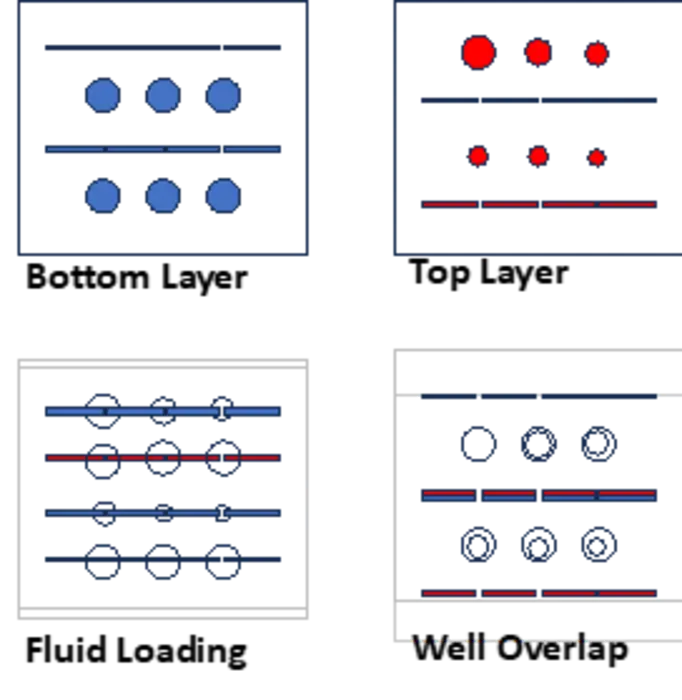

Microfluidics devices, renowned for their ability to precisely manipulate minute volumes of fluids, play a pivotal role in biological and chemical research. The SlipChip concept utilizes two layers of microfabricated PDMS—polydimethylsiloxane—with arrays of microwells that can be slipped relative to one another to mix distinct reagents passively. This design cleverly avoids the complexity of external pumps and valves and allows for the facile creation of concentration gradients, which are essential for studying dose-response relationships in assays with precious biological samples.

The multidisciplinary team, comprising experts from Japan, Argentina, and India, systematically investigated how different combinations of silicone oil viscosity and PDMS curing conditions influence the SlipChip’s mechanical and biological performance. Their groundbreaking research revealed that employing a low-viscosity silicone oil with a value of 50 centistokes (cSt) balanced the trade-offs between lubrication and sealing. Crucially, they determined that tuning PDMS fabrication parameters was essential to realizing this optimum.

Focused attention on the curing temperatures of the top and bottom PDMS layers led to what the authors term a “two-step curing approach.” The team heated the top PDMS layer at 80°C while curing the bottom layer at 60°C. This minor but strategic difference in curing conditions altered the interfacial adhesion and mechanical stiffness, allowing the layers to slip smoothly when lubricated with low-viscosity oil, while still maintaining a robust seal to prevent leakage. This innovation addressed a key bottleneck that had limited the SlipChip’s wider adoption in delicate cell assays.

This refined PDMS SlipChip technology holds tremendous promise for accelerating drug discovery pipelines. Its capacity to generate precise and reproducible concentration gradients directly on chip allows for rapid screening of cellular responses to different drug dosages while economizing sample volume and reagents. Such innovations are critical when working with scarce patient-derived cells or expensive biologics, underscoring the practical importance of this breakthrough.

Moreover, by mitigating the issues of device clogging and leakage, the system ensures more reliable long-term experimentation. This opens up exciting avenues for more complex studies, including cell-to-cell communication and interaction networks, which require stable and contamination-free microenvironments over extended periods. The SlipChip’s advantages also lend themselves well to integration with other lab-on-a-chip formats, potentially enabling multifunctional analytical platforms.

Professor Moeto Nagai, who led the investigation, emphasized the practical benefits of this enhancement in SlipChip design. He noted that the delicate balance achieved in curing conditions combined with the use of low-viscosity oil “solved a long-standing challenge” by simultaneously enabling high performance and safeguarding cell health. Thus, their approach delivers a robust platform suitable for both fundamental biological investigation and industrial applications alike.

Looking forward, the research team is enthusiastic about expanding the functional scope of their device. They plan to conduct advanced mammalian cell culture experiments in which complex gradients can be dynamically manipulated to study nuanced cellular behaviors such as differentiation, migration, and apoptosis. Additionally, the SlipChip shows potential as a tool for high-sensitivity protein detection and other bioanalytical tasks requiring minimal reagent consumption and high throughput.

This disruptive technology also holds promise for advancing personalized medicine. By enabling efficient screening of patient-specific drug responses and fostering sophisticated in vitro models of tissue microenvironments, it may reduce the time and cost associated with drug development and improve therapeutic precision. The ease of fabrication and operation further positions the PDMS SlipChip as a candidate for widespread use in both research laboratories and clinical diagnostics.

As microfluidics continues to revolutionize biomedical science, the optimization of SlipChip devices using low-viscosity silicone oils and finely controlled curing strategies represents a milestone achievement. The work exemplifies how subtle engineering modifications can overcome persistent obstacles, ultimately empowering researchers with more effective tools to interrogate biological systems at microscale with unprecedented accuracy and reliability.

The study’s findings have been published in the respected journal Micromachines, highlighting the collaborative effort’s international scientific impact. This advancement not only contributes to the microfluidics field but also inspires future innovations at the intersection of materials science, mechanical engineering, and cell biology—areas essential for the next generation of biomedical devices.

Subject of Research: Not applicable

Article Title: “PDMS SlipChip: Optimizing Sealing, Slipping, and Biocompatibility Using Low-Viscosity Silicone Oils”

News Publication Date: 29-Apr-2025

Web References:

http://dx.doi.org/10.3390/mi16050525

References:

Inaam R., Bolontrade M. F., Okamoto S., Shibata T., Santra T. S., Nagai M. (2025). PDMS SlipChip: Optimizing Sealing, Slipping, and Biocompatibility Using Low-Viscosity Silicone Oils. Micromachines, 16(5), 525.

Image Credits: COPYRIGHT(C)TOYOHASHI UNIVERSITY OF TECHNOLOGY. ALL RIGHTS RESERVED.

Keywords: Applied sciences and engineering, Life sciences

Tags: biocompatibility in cell researchdrug testing applicationsenhancing cellular experimentslow-viscosity silicone oilsmicrofabricated PDMS technologymicrofluidics device advancementsminimizing device leakage and cloggingovercoming cross-contamination challengespassive mixing in microfluidicsPDMS SlipChip optimizationpolydimethylsiloxane propertiesprecise gradient formation in assays