A groundbreaking advancement has emerged from the laboratories of Pohang University of Science and Technology (POSTECH), where a team of materials scientists and engineers has unveiled a novel nickel-based high-entropy alloy (HEA) that defies conventional thermal limitations. Spearheaded by Professor Hyoung Seop Kim, this innovative alloy maintains exceptional tensile strength and ductility across a staggering temperature spectrum ranging from cryogenic –196 °C to an intense 600 °C. This ability to remain mechanically stable across extreme temperatures signals a paradigm shift in alloy design, with profound implications for aerospace, automotive, and energy industries.

At the heart of this breakthrough lies the concept of the “Hyperadaptor,” an innovative framework introduced by the POSTECH research team. This concept encapsulates the design philosophy of alloys that inherently adapt their deformation mechanisms to varying thermal conditions, resulting in mechanical properties that remain remarkably invariant over a broad temperature range. The Hyperadaptor alloy is forged from a finely balanced mixture of multiple principal elements, which collectively form a high-entropy configuration known for enhancing material stability and complexity.

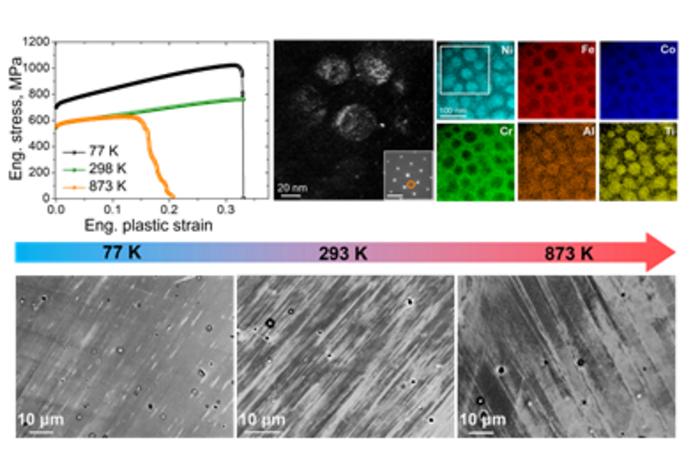

Crucially, the extraordinary thermal resilience of this nickel-based HEA is attributed to the microscopically uniform dispersion of nanoscale L1₂ precipitates within its matrix. These precipitates act as nanoscale reinforcements, impeding dislocation motion—the primary mechanism of deformation in crystalline solids—thus preserving the alloy’s strength and ductility. Remarkably, these particles retain their distribution and effectiveness even as the temperature varies dramatically, underscoring their role in stabilizing mechanical response.

Beyond the presence of L1₂ phases, the alloy’s internal structure exhibits a unique capacity to absorb and redistribute mechanical stress through temperature-independent slip behavior. Slip systems, the pathways along which atomic layers move under stress, remain active and consistent across the immense temperature span, providing the alloy with a mechanical robustness that traditional metals fail to sustain. This phenomenon highlights the synergy between microstructural engineering and intrinsic material properties that underpins the alloy’s exceptional performance.

The implications of this research extend far beyond academic curiosity. Aerospace components such as rocket engines and jet turbine blades are routinely subjected to severe temperature gradients and mechanical stresses, making reliability a paramount concern. The new HEA’s unwavering tensile properties imply a potential for enhanced safety margins and extended service lifetimes in these critical applications. Similarly, automotive exhaust systems operating under cyclic thermal loads could benefit significantly from this alloy’s capacity to resist thermal fatigue and deformation.

Further, power generation infrastructure—including turbines and pipelines—often encounters abrupt temperature shifts that induce material degradation. The Hyperadaptor alloy’s robustness could mitigate such risks, improving operational efficiency and reducing maintenance costs. By bridging the performance gaps of conventional materials, this development promises to revolutionize materials engineering and expand the horizons of high-performance alloy usage.

Professor Kim, reflecting on the significance of this innovation, emphasized that the Hyperadaptor represents a new material paradigm that transcends the conventional trade-offs between strength, ductility, and temperature sensitivity. “Our work illustrates that it is possible to engineer alloys that do not merely survive but thrive under extreme thermal variations, which was once considered unattainable,” he stated. This breakthrough paves the way for the conception of next-generation materials tailored for extreme environments.

The research, published in Materials Research Letters, not only advances the scientific understanding of high-entropy alloys but also elucidates the fundamental mechanisms by which nanoscale precipitates and microstructural design can decouple mechanical performance from temperature dependency. This knowledge could serve as a blueprint for engineering other alloy systems aimed at high-demand sectors.

Supported by the Ministry of Science and ICT through their Nano and Materials Technology Development Program alongside Hyundai Motor Group, this project exemplifies successful collaboration between academia and industry. Such partnerships are crucial for translating fundamental research innovations into tangible technological advancements that can be incorporated into manufacturing and industrial applications.

As materials science pushes the boundaries of what metals can achieve, the Hyperadaptor alloy stands as a testament to the potential unlocked by meticulously crafted compositions and nanostructural control. Going forward, continued research will likely explore the scalability of production and the alloy’s performance in complex, real-world conditions, broadening its prospective deployment.

In summation, the development of this nickel-based high-entropy alloy ushers in a new era of materials capable of adapting seamlessly to extreme temperature fluctuations without sacrificing mechanical integrity. This innovation holds the promise of safer, more reliable, and more efficient components across a multitude of high-stakes engineering fields—marking a defining moment in the evolution of advanced alloy design.

Subject of Research: Development of a nickel-based high-entropy alloy exhibiting temperature-insensitive tensile properties across a wide temperature range

Article Title: Hyperadaptor; Temperature-insensitive tensile properties of Ni-based high-entropy alloy a wide temperature range

News Publication Date: 6-Feb-2025

Web References:

http://dx.doi.org/10.1080/21663831.2025.2457346

Image Credits: POSTECH

Keywords

Applied sciences and engineering; Alloy behavior; Aerospace engineering; Automotive engineering; Ductility; Temperature; Mechanical stress; Metal stress; Rockets; Low temperature physics; Environmental engineering; Research and development

Tags: aerospace materials advancementsautomotive engineering innovationscryogenic temperature applicationsenergy industry materialshigh-temperature alloy performanceHyperadaptor framework for alloysmaterials science breakthroughsmechanical stability in extreme temperaturesnickel-based high-entropy alloyPOSTECH research in metallurgytensile strength and ductilitythermal limitations in metals