In a groundbreaking study published in the journal Engineering, researchers are making significant strides towards enhancing the toughness of polypropylene (PP), a thermoplastic polymer widely utilized across various industries. The collaborative effort led by Zhiyi Zhang and Qiang Zheng from Taiyuan University of Technology and Zhejiang University presents a novel solution that addresses the persistent challenge of low-temperature toughness in polypropylene. This innovation is crucial for applications that require durable materials capable of withstanding colder conditions without losing integrity.

Polypropylene, known for its resilience against thermal and chemical degradation, has one major limitation: its brittleness at low temperatures. This property can severely restrict its application range from automotive components to packaging materials, which often face harsh environmental conditions. To combat this, the research team has developed a unique core-shell structured composite that effectively enhances the material’s performance. By strategically blending polypropylene with high-density polyethylene (HDPE) and polystyrene–polyethylene–polypropylene–polystyrene (SEPS), they created a complex material with improved mechanical properties.

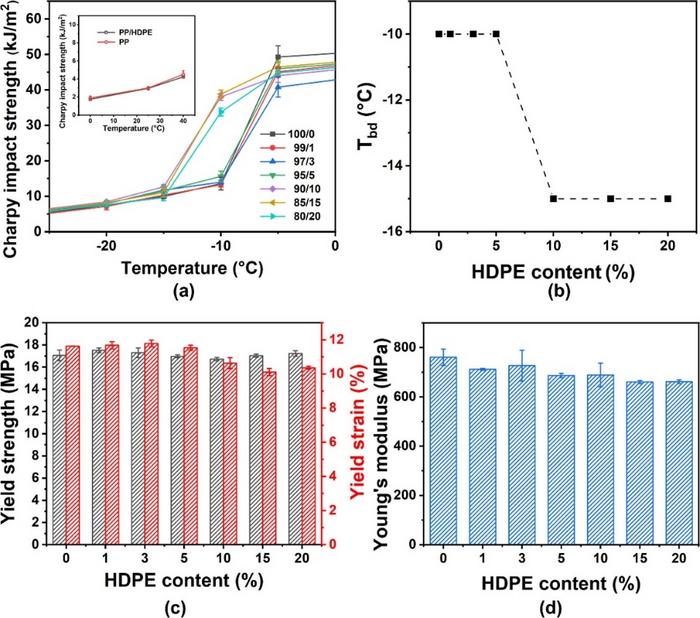

The research notably introduces the SEPS@HDPE core-shell structure, wherein SEPS functions as the core and HDPE acts as the shell. This configuration is particularly innovative, as it not only modifies the material’s mechanical characteristics but also improves thermal behavior. The findings show that the incorporation of HDPE facilitates a notable transition in the composite’s toughness, specifically in the transition temperature known as Tbd, allowing it to adapt more effectively to differing temperature ranges.

Experimental results from the research indicate a dramatic improvement in the impact strength of the PPM/HDPE composites—the specific composite derived from blending PP with SEPS and HDPE. Data reveals that adding HDPE enhances the impact resistance significantly at low temperatures. For instance, at just 10 °C, the material’s impact strength sees an impressive jump from 13.6 to 49.3 kJ/m² when tested at −5 °C. Such enhancements illustrate the potential of this new composite to function effectively in environments that traditional polypropylene would falter in.

Furthermore, the study meticulously examines the phase morphology of the developed composites. Through advanced imaging techniques such as scanning electron microscopy and transmission electron microscopy, the team discovered that the introduction of HDPE not only reduces the size of the dispersed SEPS particles but also promotes a more homogeneous distribution throughout the matrix. At lower concentrations of HDPE, the dispersed phase exhibits a stacked configuration; however, increasing the HDPE content leads to the formation of a distinct core-shell structure—pivotal for the improved mechanical attributes.

Rheological assessments of the composites add another layer of understanding to this research. The behavior of the materials under stress demonstrates that a modest concentration of HDPE—around 3%—facilitates the formation of a physical network of SEPS particles, significantly enhancing the overall material performance. Conversely, excessive HDPE (beyond 10%) begins to diminish these networks, leading to a decline in the beneficial effects observed at lower levels. This balance is critical for scientists and engineers seeking optimal formulations in composite materials.

The underlying toughening mechanism elucidated in the study can be linked directly to the core-shell structure. The introduction of HDPE has a dual effect: it not only curbs the coalescence of SEPS droplets but also establishes a unique intermediate layer that serves to disperse stress more effectively throughout the material. This architecture allows for greater matrix shear yielding while concurrently suppressing the progression of cracks—a cause of failure in polymer composites.

Beyond its immediate scientific impact, this research opens doors to new methodologies for improving the resilience of various thermoplastics. The insights gained from the toughening mechanisms of the PPM/HDPE composites could have broader implications for multiple thermoplastic materials employed in demanding environments, from industrial applications to consumer products.

Focusing on the potential applications, the enhanced toughness of PP composites presents numerous opportunities across the automotive and packaging sectors. Vehicles that are required to endure extreme temperatures could benefit substantially from these advances—offering improvements in safety, longevity, and performance. Similarly, the packaging industry could implement these findings to produce materials that withstand stress without compromising the integrity of contained products.

The implications of the research extend to the sustainability of materials science as well. As industries increasingly seek environmentally friendly materials, the synergistic blending of existing polymers like PP and HDPE could lead to solutions that are both economically viable and ecologically sustainable. This aligns with global efforts to innovate more sustainable manufacturing practices while maintaining product efficacy and safety.

In conclusion, the work conducted by Zhiyi Zhang and Qiang Zheng and their colleagues not only enhances our fundamental understanding of composite materials but also contributes practical solutions for low-temperature applications. As research continues in materials science, these advancements in polymer mechanics and phase morphology may herald a new era of robust, versatile materials suited for harsher operating conditions. The full implications of this research could reshape how materials are developed and used across various industries, driving further exploration into the realms of composite functionality and performance enhancement.

With such promising results and a thorough investigation into both the structural and mechanical attributes of the new composites, the future of polypropylene and its derivatives looks brighter than ever.

Subject of Research: Enhancements in the Toughness of Polypropylene Composites

Article Title: Phase Morphology Evolution and Rheological Behavior of Toughened Polypropylene Composite with Controllable Brittle soft-core hard-shell Ductile Transition Temperature Using SEPS@HDPE Core soft-core hard-shell Shell Structure

News Publication Date: 10-Dec-2024

Web References: DOI Link

References: Engenharia Journal, Open Access Paper

Image Credits: Jiahao Shen et al.

Keywords

Thermoplastic Composites, Polypropylene, Toughness, Low-temperature Applications, Core-shell Structure, Mechanical Properties, Rheological Behavior, Phase Morphology, HDPE, SEPS.

Tags: automotive material advancementscollaborative materials science studiescore-shell composite materialsdurability in harsh conditionsenhanced polypropylene toughnesslow-temperature performance of polymersmechanical properties of polypropylene compositespackaging material improvementspolypropylene applications in cold environmentsSEPS@HDPE structure developmentthermoplastic polymer innovationsthermoplastic polymer research