Plastics are indispensable materials in modern society, utilized extensively across various industries and everyday applications due to their lightweight nature, durability, and adaptability. However, this reliance comes at a significant environmental cost, with the world generating an astonishing 52 million tons of plastic waste each year. Such figures highlight plastic pollution as a critical global issue, prompting scientists and researchers to seek sustainable alternatives to conventional plastic materials. The challenges associated with traditional polymers, particularly their complex synthesis processes and difficulties in separation during recycling, demand innovative solutions.

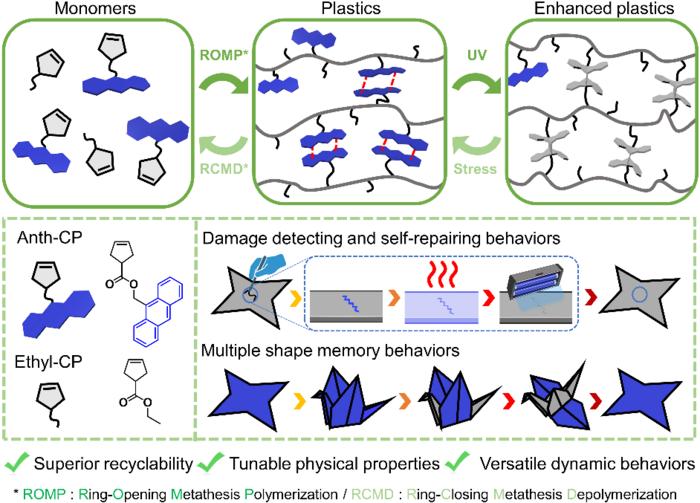

In a noteworthy breakthrough, a team of scientists led by Dr. Tae Ann Kim at the Korea Institute of Science and Technology (KIST) has engineered a revolutionary polymeric material that combines self-healing capabilities with enhanced recyclability. This development marks a significant advancement in polymer science, as the new material demonstrates remarkable versatility while being environmentally friendly. The research team’s core innovation revolves around a uniquely designed pentagonal ring-structured molecule, which facilitates dynamic covalent exchange reactions when subjected to heat, light, or mechanical stress. This molecular architecture allows the transformation between monomers and polymers, paving the way for materials that exhibit properties ranging from the soft elasticity of rubber to the rigidity characteristic of glass.

The newly synthesized polymer stands out due to its ability to emit fluorescence at sites of damage, allowing for real-time detection of compromises in its structure. This is particularly useful in applications where material integrity is paramount. Furthermore, the self-healing properties of this polymer activate upon exposure to heat and light, demonstrating an elegant solution to physical wear and tear—a feature that could dramatically extend the life cycle of various products made from this material. Upon reaching the end of its life, the innovative properties of this polymer come into play, as it can selectively depolymerize back into its monomers, even when intermixed with conventional plastics. This property allows for the regeneration of the original polymer without loss of its intrinsic characteristics, thus addressing one of the most pressing challenges in plastic waste management.

In addition to its recyclability, the polymer’s dynamic response to external stimuli—heat, light, and mechanical forces—enables it to alter its thermal, mechanical, and optical properties as required. The creation of protective coatings using this material has also proven advantageous, delivering performance metrics that are substantially superior to conventional epoxy coatings. Specifically, the hardness of this new polymer can be up to three times greater, while its elastic modulus surpasses that of existing counterparts by more than double. Such enhancements are vital for applications prone to wear, such as automotive coatings or infrastructure.

Moreover, the interaction between ultraviolet light and this polymer significantly strengthens molecular bonds, allowing for the fixation of predefined shapes. This shape memory capability opens new avenues in diverse fields, including smart textiles, wearable tech, and advanced robotics, where tailored properties and responsive actions are increasingly desired. Not only does this innovation hold the potential to enrich the material sciences domain, but it also aligns with a growing demand for sustainable materials that encapsulate a wide range of functionalities.

Dr. Tae Ann Kim, a leading figure in this research, articulates the pivotal shift this work represents in the field of materials science. He emphasizes that the innovative design of materials with autonomous functionalities, including damage detection and self-healing mechanisms, transcends the conventional limitations of recyclable plastics. The commitment to advancing the market for eco-friendly coatings further accentuates the importance of this research; coatings that necessitate minimal maintenance while generating virtually no waste could redefine industrial practices.

As awareness regarding the environmental impact of plastic waste escalates, this novel polymeric material presents a compelling solution. It not only reduces economic burdens associated with sorting and processing mixed plastic waste but also advocates for a future where sustainability and performance coexist harmoniously. By integrating high-performance polymers into industrial coatings, businesses can expect a significant reduction in maintenance costs while simultaneously contributing to ecological preservation.

This research was meticulously supported by the National Research Council of Science and Technology (NST) grant (CRC22033-230) of the Ministry of Science and ICT, showcasing the importance of collaborative funding in pioneering scientific endeavors. The findings were published in the esteemed journal Advanced Functional Materials, underscoring the scientific community’s recognition of this impactful work.

In summation, the endeavor to create a polymer that not only serves the needs of manufacturing and consumer products but also addresses critical environmental issues represents a remarkable achievement. The capabilities of self-healing, damage detection, and high recyclability significantly advance our approach to material science. This research reaffirms the potential for innovative materials to reshape industries and our interactions with the environment, paving the way for a sustainable future.

Subject of Research: Sustainable polymeric materials with self-healing capabilities and high recyclability

Article Title: High-Performance Dynamic Photo-Responsive Polymers With Superior Closed-Loop Recyclability

News Publication Date: 19-Feb-2025

Web References: DOI: 10.1002/adfm.202414842

References: National Research Council of Science and Technology (NST) grant CRC22033-230, Nano & Material Technology Development program RS-2024-00448445

Image Credits: Korea Institute of Science and Technology

Keywords

Sustainable polymers, self-healing materials, recyclability, advanced coatings, polymer science, environmental impact, dynamic materials, smart textiles, robotics, eco-friendly technology.

Tags: alternatives to conventional plasticsdynamic covalent exchange reactionseco-friendly material developmentenhanced recyclability in materialsenvironmental impact of plasticsinnovative polymer synthesispentagonal ring-structured moleculespolymer science advancementsreducing plastic pollutionself-healing polymer technologysustainable smart polymerszero-waste materials