Acetic acid, also known as acetate, and other products that can be developed from acetic acid are used in a variety of industries, from food production to medicine to agriculture. Currently, acetate production uses a significant amount of energy and results in harmful waste products. The efficient and sustainable production of acetate is an important target for researchers interested in improving industrial sustainability.

Credit: Carbon Future, Tsinghua University Press

Acetic acid, also known as acetate, and other products that can be developed from acetic acid are used in a variety of industries, from food production to medicine to agriculture. Currently, acetate production uses a significant amount of energy and results in harmful waste products. The efficient and sustainable production of acetate is an important target for researchers interested in improving industrial sustainability.

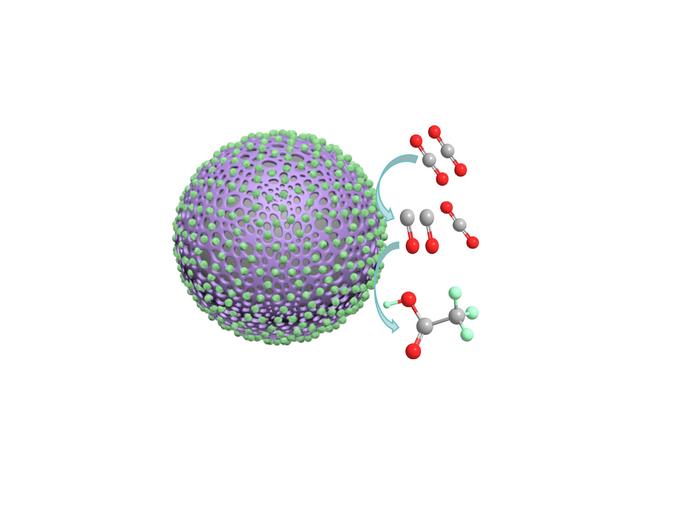

A paper published in Carbon Future on July 9 outlines a method using a polyaniline catalyst with cobalt oxide nanoparticles to produce acetate through carbon dioxide electroreduction.

“The polyaniline catalyst with cobalt oxide nanoparticles has two components—polyaniline as a continuous material and cobalt oxide as nanoparticles dispersed on the polyaniline. This cooperative structure makes a highly selective catalyst that can produce acetate during carbon dioxide electroreduction. Cobalt oxide is in charge to produce carbon monoxide intermediate and then pass them to polyaniline, where acetate is formed by electroreduction,” said Liwen Wang, a professor at the School of Chemistry and Chemical Engineering at Nanjing University in Nanjing, China.

Polyaniline is a conducting polymer that has been proven to be a highly selective catalyst used in the generation of other carbon products. This study looks at the role of polyaniline and the mechanism of carbon dioxide electroreduction over the polyaniline surface. A higher carbon monoxide concentration on the polyaniline enhances carbon to carbon coupling on the catalyst surface. Adding cobalt oxide nanoparticles as a supplementary catalyst creates a tandem reaction that is highly selective for acetate.

“This configuration facilitates a higher local carbon monoxide concentration over polyaniline and enhances carbon-to-carbon coupling. The non-metallic polyaniline material can provide excellent performance in electrocatalysts,” said Wang. She went on to describe the synergy between the polyaniline material and the cobalt oxide nanoparticles. “The polyaniline provides available active sites for increasing the carbon-to-carbon coupling, while the cobalt oxide nanoparticles offer a large number of carbon monoxide intermediates.”

To measure how well the polyaniline/cobalt oxide catalyst worked, researchers also prepared two control samples: a polyaniline catalyst without cobalt oxide and a cobalt oxide catalyst. The polyaniline/cobalt oxide catalyst had improved crystallization with a larger crystal size and uniform deposits of the cobalt oxide nanoparticles. The polyaniline coating also meant there was a higher surface area, which most likely meant there were more sites for the electro-conversion of carbon dioxide. A test called an electron pragmatic resonance (EPR) measurement showed that the polyaniline/cobalt oxide catalyst had more oxygen vacancies, which trap the carbon dioxide and allow the proton-electron transfers necessary for the transformation.

Additional testing went on to confirm that it was not the cobalt oxide or the polyaniline alone that accounted for the improved performance of the polyaniline/cobalt oxide catalyst. It was the synergistic nature of the polyaniline and cobalt oxide together.

Looking ahead, researchers hope to continue improving the synergistic performance between polyaniline and cobalt oxide on this catalyst. “The next step is to optimize the catalyst system, enhancing the tandem effect for better performance. The ultimate goal is the direct electrosynthesis of acetate using carbon dioxide and water as raw materials,” said Wang.

Other contributors include Pengfei Liu and Qiang Wang of Nanjing Tech University in Nanjing, China; and Jie Yang, Chenjia Liang, Changshun Deng, Yinxuan Zhao, Xuefeng Guo, Luming Peng, Nianhua Xue, and Weiping Ding of Nanjing University in Nanjing, China.

The National Science Foundation of China and the Ministry of Science and Technology of China supported this research.

About Carbon Future

Carbon Future is an open access, peer-reviewed and international interdisciplinary journal, published by Tsinghua University Press and exclusively available via SciOpen. Carbon Future reports carbon-related materials and processes, including catalysis, energy conversion and storage, as well as low carbon emission process and engineering. Carbon Future will publish Research Articles, Reviews, Minireviews, Highlights, Perspectives, and News and Views from all aspects concerned with carbon. Carbon Future will publish articles that focus on, but not limited to, the following areas: carbon-related or -derived materials, carbon-related catalysis and fundamentals, low carbon-related energy conversion and storage, low carbon emission chemical processes.

About SciOpen

SciOpen is an open access resource of scientific and technical content published by Tsinghua University Press and its publishing partners. SciOpen provides end-to-end services across manuscript submission, peer review, content hosting, analytics, identity management, and expert advice to ensure each journal’s development. By digitalizing the publishing process, SciOpen widens the reach, deepens the impact, and accelerates the exchange of ideas.

Journal

Carbon Future

DOI

10.26599/CF.2024.9200013

Article Title

CO2 electroreduction to acetate by enhanced tandem effects of surface intermediate over Co3O4 supported polyaniline catalyst

Article Publication Date

9-Jul-2024