They published their work on Mar. 20, 2024, in Energy Material Advances.

Credit: Jiantao Wang, National Power Battery Innovation Center, China Automotive Battery Research Institute Co., Ltd, General Research Institute for Nonferrous Metals.

They published their work on Mar. 20, 2024, in Energy Material Advances.

“TR poses a critical safety concern for HED LIBs,” said paper author Jiantao Wang, the general manager of National Power Battery Innovation Center, the general manager of China Automotive Battery Research Institute Co., Ltd, professor in General Research Institute for Nonferrous Metals. “It hinders HED LIBs wide application in electric vehicles.”

Wang explained that TR can occur during various mechanical abuse, electrical abuse, and thermal abuse scenarios of LIBs, and involves complicated cell failure processes including ISC because of separator malfunction, thermochemical reactions between active materials, and combustion of organic liquid electrolytes.

“These processes start at different temperature thresholds and may occur successively or concurrently, leading to different cell safety failure pathways,” Wang said. “Oxygen released from the cathode phase transition reacts with organic liquid electrolytes or anodes to generate amounts of heat, which is usually a direct reason for the TR of LIBs. However, this thermochemical reaction generally happens above 160oC, resulting in the combustion of organic liquid electrolytes.”

Before that, polyolefin (PE)-based separators with low melting points of approximately 135oC, could shrink, soften and even meltdown due to overpressure and overheating of LIBs. Leading to cell ISC with the rapid release of electrical energy, ultimately triggering the failure of LIBs. According to Wang, researchers have been actively exploring modification strategies to develop functional separators for enhancing the safety of LIBs during thermal abuse

Inorganic ceramics, such as Al2O3, SiO2, ZrO2 and TiO2, have been widely used as coating materials to enhance the thermal deformation of separators. Wang said, although helpful to prevent the thermal deformation of separators at high temperatures, they can also block the transportation of lithium-ion in LIBs and harm the electrochemical performance.

“Recently, oxide solid-state electrolyte materials, such as Li0.5La0.5TiO3 (LLTO), Li1.5Al0.5Ti1.5(PO4)3 (LATP) and Li7La3Zr2O12 (LLZO), are deemed as promising coating materials due to superior lithium-ion conductivity. The functional separators co-coated with inorganic oxides and organic polymers have been reported wildly,” Wang said.

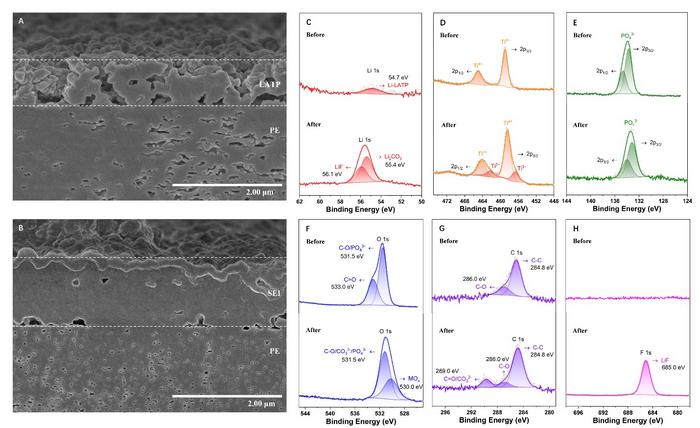

“However, the synergistic impact of inorganic ceramics and solid-state electrolyte co-coating on separators is scarcely addressed in the existing literature,” Wang said. “In this study, we propose PE separators co-coated with boehmite ceramics and LATP solid-state electrolytes to bolster safety by addressing thermal deformation and to mitigate detrimental effects on electrochemical performance.”

“HED (~350Wh/kg) pouch cells were assembled with nickel-rich Li(Ni0.9CoxMn0.1-x)O2 cathodes and high-capacity silicon-based/graphite blended anodes. We design the LATP-coated side of separators placed against the anode laminates,” Wang said.

It is found that LATP reacts with the organic liquid electrolytes and lithium to generate a robust SEI-filled LATP layer during the formation, which can prevent the thermal deformation of separators. Wang said, during the thermal abusive tests, the battery’s TR failure thresholds raised from 146.2oC to 162.0oC. Correspondingly, the direct failure cause of the cell TR hurdled the separator malfunction to the thermochemical reactions of the nickel-rich cathodes.

“We also evaluated the electrochemical performance of these pouch cells to ensure their reliability for practical applications,” Wang said. “pouch cells exhibited impressive electrochemical performance, maintaining a capacity retention of 87.99% after 500 cycles at 1C.”

Jiantao Wang is also affiliated with National Power Battery Innovation Center, China Automotive Battery Research Institute Co., Ltd, and General Research Institute for Nonferrous Metals. Other contributors include Tianhang Zhang, Bo Wang, Xiaopeng Qi, Zenghua Chang, Rennian Wang, Bing Yu and Rong Yang, National Power Battery Innovation Center, China Automotive Battery Research Institute Co., Ltd, General Research Institute for Nonferrous Metals.

This work is supported by National Natural Science Foundation of China (No. U21A2080); National Key Research and Development Program of China (No. 2022YFE0202400); Beijing Natural Science Foundation (No. JQ22028); Jilin Province Science and Technology Major Project (No. 20210301021GX); Youth Talent Support Program (No. SQ2022QB02427); Youth Foundation of China GRINM Group Corporation Limited (No. 2023HX012).

###

Reference

Authors: TIANHANG ZHANG, BO WANG, XIAOPENG QI, ZENGHUA CHANG, RENNIAN WANG, BING YU, RONG YANG, AND JIANTAO WANG

Title of original paper: Improving the Safety of HED LIBs by Co-Coating Separators with Ceramics and Solid-State Electrolytes

Journal: Energy Material Advances

DOI: 10.34133/energymatadv.0085

Affiliations: 1National Power Battery Innovation Center, China GRINM Group Corporation Limited, Beijing 100088, China. 2China Automotive Battery Research Institute Co., Ltd., Beijing 100088, China. 3General Research Institute for Nonferrous Metals, Beijing 100088, China.

About the Author: Jiantao Wang is the general manager of the National Power Battery Innovation Center, the general manager of China Automotive Battery Research Institute Co., Ltd, and a professor at the General Research Institute for Nonferrous Metals, recipient of the 2015 Beijing Nova program. He obtained his B.S. in Analytical Chemistry from the University of Science and Technology Beijing in 2006, and received his Ph.D. in Organic Chemistry from the Technical Institute of Physics and Chemistry, Chinese Academy of Sciences, in 2011. His research interests include advanced electrode materials, high-energy Li-ion batteries and solid-state batteries.

Journal

Energy Material Advances

DOI

10.34133/energymatadv.0085

Method of Research

Experimental study

Subject of Research

Not applicable

Article Title

Improving the Safety of HED LIBs by Co-Coating Separators with Ceramics and Solid-State Electrolytes

Article Publication Date

20-Mar-2024