This research is led by Donghee Park (Center for Opto-Electronic Materials and Devices, Post-Silicon Semiconductor Institute, Korea Institute of Science and Technology, Republic of Korea) and Dong Ick Son (Institute of Advanced Composite Materials, Korea Institute of Science and Technology; KIST School, Department of Nanomaterials and Nano Science, University of Science and Technology, Republic of Korea)

Credit: Beijing Zhongke Journal Publising Co. Ltd.

This research is led by Donghee Park (Center for Opto-Electronic Materials and Devices, Post-Silicon Semiconductor Institute, Korea Institute of Science and Technology, Republic of Korea) and Dong Ick Son (Institute of Advanced Composite Materials, Korea Institute of Science and Technology; KIST School, Department of Nanomaterials and Nano Science, University of Science and Technology, Republic of Korea)

Recently, many scientists have been developing eco-friendly energy sources to replace fossil fuels to minimize global warming that threatens the global ecosystem. One of the notable studies is photoelectrochemical (PEC) cells that use infinite solar energy as an energy source to generate eco-friendly hydrogen through PEC reactions. The PEC process is a light-induced reaction that generates hydrogen gases through water decomposition, providing eco-friendly hydrogen generations via photocatalytic reactions on semiconductor electrodes. Moreover, it exhibits a significantly high solar-to-hydrogen (STH) conversion efficiency. Therefore, the PEC process is more efficient than the water-splitting method based on electrocatalysis using continuous electricity because the PEC process uses solar energy. The enlarged surface area of photoanode in PEC cells has been a well-known approach for compensating for high recombination losses of photogenerated electron-hole pairs. Nano-structured photoactive materials could enlarge the specific surface area with electrolytes and increase light absorption. Despite these efforts to engineer photoactive material layers, the improvement of hydrogen generations for practical applications remains challenging.

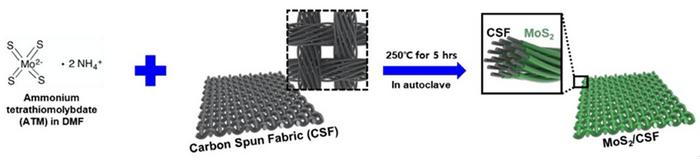

Carbon fiber textiles like carbon fiber bundles or carbon spun fabric (CSF) have been considered one of the promising electrode materials for PEC applications because of their chemical and mechanical stability, flexibility, conductivity, and especially porosity. When hydrothermal methods were employed in previous studies, decorative materials on carbon fiber textiles grew in nanoflakes or nanorods, providing an enlarged surface area on the top and an enhanced photochemical performance. Compared to rigid and planar substrates, their porous structure eases fabrications of large-area 3D composite structures with enlarged interface areas that interact with electrolytes. These results show that optimizing nanostructures on porous carbon textiles as the substrate is critical; however, the correlation between the coating morphologies and the PEC performances has not yet been studied.

Meanwhile, MoS2 has been adopted in various fields: batteries, electronics, and catalysts. MoS2 has advantages for the photoanode of PEC cell systems considering optical and structural properties. The conduction band (CB) of MoS2 is higher than the reduction potential of H+/H2 (-4.44 eV), and the valence band of MoS2 is lower than the oxidation potential of O2/H2O (-5.67 eV) at the vacuum level. MoS2 has a bandgap of 0.86 eV to 1.9 eV, depending on the structure or the thickness. MoS2-based heterostructures with other semiconductors were effective in promoting hydrogen generation. These results also suggest that the coating morphologies of the bottom layer should be optimized to synthesize the top layer.

In this study, the PEC performances of photoanodes with MoS2 on a 3D CSF and the effects of MoS2 coating morphologies on the PEC performances were presented. 3D porous MoS2/CSF photoanodes were fabricated using a low-temperature hydrothermal coating method. When MoS2 coating morphologies were optimized depending on the amount of MoS2 precursor and hydrothermal growth time, film-like MoS2 on CSF had the largest surface area and the highest photocurrent density. Moreover, conformal MoS2/TiO2 heterojunction structures on 3D porous CSFs were fabricated using sputtering processes for the bottom layer (TiO2) and hydrothermal synthesis for the top layer (MoS2). The PEC performances of the PEC cell with the MoS2/TiO2/CSF photoanode were further improved compared to the PEC cell with the MoS2/CSF structure.

See the article:

High-performance photoelectrochemical cells with MoS2 nanoflakes/TiO2 photoanode on 3D porous carbon spun fabric

https://doi.org/10.1016/j.asems.2023.100088

Journal

Advanced Sensor and Energy Materials

DOI

10.1016/j.asems.2023.100088

Article Title

High-performance photoelectrochemical cells with MoS2 nanoflakes/TiO2 photoanode on 3D porous carbon spun fabric

Article Publication Date

19-Dec-2023