Pulsed laser ablation in liquid (PLAL) is a reliable and versatile technique for producing metal nanoparticles (NPs) in solution. Its advantages, including the absence of reducing agents, operational simplicity, high purity without purification steps, and ambient processing conditions, make it a preferred choice over conventional metal NP preparation approaches like the chemical reduction method. The widespread adoption of PLAL across scientific and industrial research fields attests to its utility. However, the size and maintenance cost of traditional laser sources pose significant challenges for laboratories, particularly those not specialized in laser science.

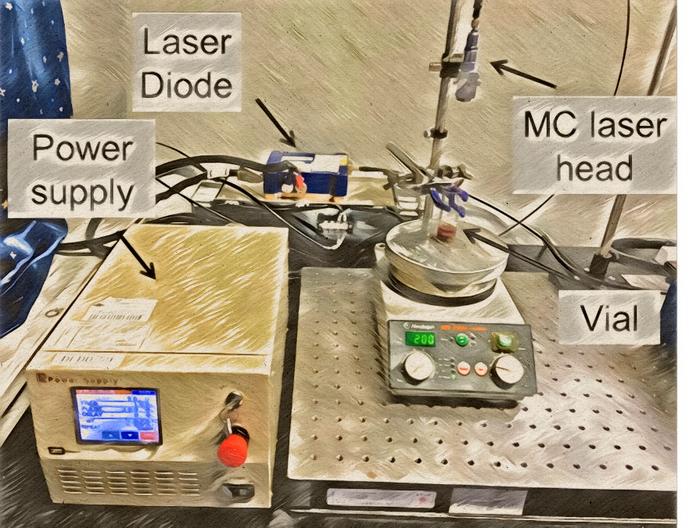

Credit: Yumi Yakiyama and Hidehiro Sakurai, Osaka University, Japan.

Pulsed laser ablation in liquid (PLAL) is a reliable and versatile technique for producing metal nanoparticles (NPs) in solution. Its advantages, including the absence of reducing agents, operational simplicity, high purity without purification steps, and ambient processing conditions, make it a preferred choice over conventional metal NP preparation approaches like the chemical reduction method. The widespread adoption of PLAL across scientific and industrial research fields attests to its utility. However, the size and maintenance cost of traditional laser sources pose significant challenges for laboratories, particularly those not specialized in laser science.

Recognizing these hurdles, Professors Hidehiro Sakurai, Yumi Yakiyama and their team at Osaka University turned their attention to the microchip laser (MCL) system. Developed by the Taira group at the Institute of Molecular Science (IMS), MCL is a compact, low-power consumption giant-pulse laser system with a short cavity length of under 10 mm, making it well-suited for standard organic synthesis laboratories. This work is published in the journal Industrial Chemistry & Materials on January 5.

Despite the advantage of its size, the applicability of MCL’s specifications, especially its small pulse energy, to PLAL of an Au target was unknown. The research team aimed to understand how the differences in instrumental specifications contribute to the outcomes of PLAL of Au, with the goal of furthering benchtop synthesis and the direct application of NPs for catalytic purposes.

In their investigation, the team utilized MCL for PLAL of Au, focusing on the effects of small laser pulse energy (0.5 mJ), short pulse duration (0.9 ns), and low repetition rate (10 Hz) on ablation efficiency. The results revealed that MCL exhibited relatively high ablation efficiency despite having a much smaller pulse energy compared to conventional higher-power lasers (25 mJ/pulse, 12 ns duration, 10 Hz).

“Our study provides new insights into the preparation of Au NPs using the compact MCL system. Importantly, it opens avenues for the direct use of highly reactive NPs prepared by MCL in the development of new catalytic reactions within standard synthetic chemistry laboratories,” Sakurai emphasized.

The research team includes Barana Sandakelum Hettiarachchi, Yusuke Takaoka, Yuta Uetake, Yumi Yakiyama, and Mihoko Maruyama, Yusuke Mori, Hiroshi Y. Yoshikawa, and Hidehiro Sakurai from Osaka University; and Hwan Hong Lim, and Takunori Taira from the Institute of Molecular Science.

This research is funded by JSPS KAKENHI and Amada Foundation for the Promotion of Science & Engineering.

Industrial Chemistry & Materials is a peer-reviewed interdisciplinary academic journal published by Royal Society of Chemistry (RSC) with APCs currently waived. Icm publishes significant innovative research and major technological breakthroughs in all aspects of industrial chemistry and materials, especially the important innovation of the low-carbon chemical industry, energy, and functional materials.

Journal

Industrial Chemistry and Materials

DOI

10.1039/D3IM00090G

Method of Research

Experimental study

Subject of Research

Not applicable

Article Title

Uncovering gold nanoparticle synthesis using a microchip laser system through pulsed laser ablation in aqueous solution

Article Publication Date

5-Jan-2024