An international research group has engineered a novel high-strength flexible device by combining piezoelectric composites with unidirectional carbon fiber (UDCF), an anisotropic material that provides strength only in the direction of the fibers. The new device transforms kinetic energy from the human motion into electricity, providing an efficient and reliable means for high-strength and self-powered sensors.

Credit: Tohoku University

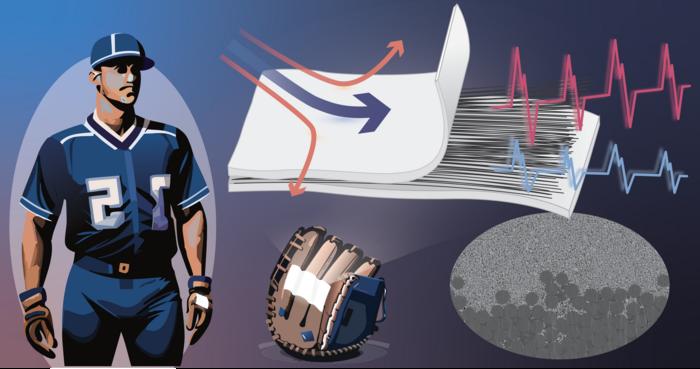

An international research group has engineered a novel high-strength flexible device by combining piezoelectric composites with unidirectional carbon fiber (UDCF), an anisotropic material that provides strength only in the direction of the fibers. The new device transforms kinetic energy from the human motion into electricity, providing an efficient and reliable means for high-strength and self-powered sensors.

Details of the group’s research were published in the journal Small on Dec.14, 2023.

Motion diction involves converting energy from the human motion into measurable electrical signals and is something crucial for ensuring a sustainable future.

“Everyday items, from protective gears to sports equipment, are connected to the internet as part of the Internet of Things (IoT), and many of them are equipped with sensors that collect data,” says Fumio Narita, co-author of the study and professor at Tohoku University’s Graduate School of Environmental Studies. “And effective integration of these IoT devices into personal gear requires innovative solutions in power management and material design to ensure durability, flexibility.”

Mechanical energy can be utilized thanks to piezoelectric materials’ ability to generate electricity when physically stressed. Meanwhile, carbon fiber lends itself to applications in the aerospace and automotive industries, sports equipment, and medical equipment because of its durability and lightness.

“We wondered if personal protective equipment, made flexible using a combination of carbon fiber and a piezoelectric composite, could offer comfort, more durability, and sensing capabilities,” says Narita.

The group fabricated the device using a combination of unidirectional carbon fiber fabric (UDCF) and potassium sodium niobate (KNN) nanoparticles mixed with epoxy (EP) resin. The UDCF served as both an electrode and a directional reinforcement.

The so-called UDCF/KNN-EP device lived up to its expectations. Tests revealed that it could maintain high performance even after being stretched more than 1000 times. It has been proven that it can withstand a much higher load when pulled along the fiber direction compared to other flexible materials. Additionally, when subjected to impacts and stretching perpendicular to the fiber direction, it surpasses other piezoelectric polymers in terms of energy output density. Notably, the mechanical and piezoelectric responses of UDCF/KNN-EP were analyzed using multiscale simulations in collaboration with Professor Uetsuji’s group at the Osaka Institute of Technology.

The UDCF/KNN-EP will help propel the development of flexible self-powered IoT sensors, leading to advanced multifunctional IoT devices.

Narita and his colleagues are also excited about the technological advancements of their breakthrough. “CF/KNN-EP was integrated into sports equipment and accurately detected the impact from catching a baseball and a person’s step frequency. In our work, the high strength of CFs was leveraged to improve the sustainability and reliability of battery-free sensors while maintaining their directional stretchability and provides valuable insights and guidance for future research in the field of motion detection.”

Journal

Small

DOI

10.1002/smll.202307689

Article Title

Fabrication, Evaluation, and Multiscale Simulation of Piezoelectric Composites Reinforced Using Unidirectional Carbon Fibers for Flexible Motion Sensors

Article Publication Date

14-Dec-2023