Magnesium, the lightest metallic structural material, has been referred to as the most promising material for green engineering in the 21st century. Currently, magnesium finds extensive application in various sectors, including automotive manufacturing, railway transportation, 3C consumer electronics, aerospace production, and within prominent companies like Tesla and Apple.

Credit: Xiaorui Huang, et al

Magnesium, the lightest metallic structural material, has been referred to as the most promising material for green engineering in the 21st century. Currently, magnesium finds extensive application in various sectors, including automotive manufacturing, railway transportation, 3C consumer electronics, aerospace production, and within prominent companies like Tesla and Apple.

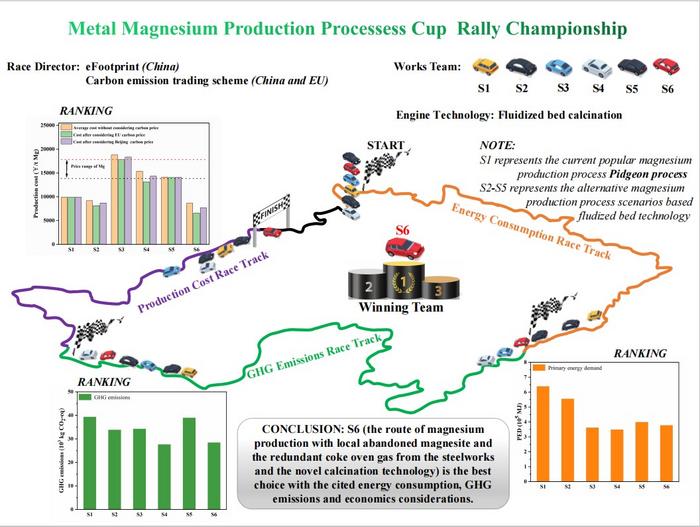

In China, nearly all magnesium produced is done via the Pidgeon process. which involves the thermal reduction of calcined dolomite with ferrosilicon. Due to its inherent characteristics, however, this method generates large amounts of greenhouse gases (GHG) along with high consumption of fossil fuels.

To address this limitation, a team of researchers in China conducted a life cycle assessment (LCA) to investigate the energy consumption and GHG emissions associated with the Pidgeon process and five other alternative methods.

“We conducted the study at Fugu County, China’s largest magnesium production site. We developed a cradle-to-gate life cycle model for Fugu magnesium, leveraging local technical processes and production data. This approach allows us to gain clear insights into the key factors for conserving energy and reducing carbon emissions within magnesium production,” shared the study’s first author, Xiaorui Huang, a PhD student at the Shenyang University of Chemical Technology.

Notably, the energy consumption and GHG emissions data for the current Pidgeon process in Fugu were recently updated, with figures of 6.38×105 MJ and 39.3 t CO2-eq., respectively.

“These figures are derived from the Chinese database and accurately portray the current state of domestic magnesium production technology. They hold substantial importance in establishing the initial carbon quota for the domestic magnesium industry,” explained Mr. Huang.

The researchers also noted that a new magnesium production technology using Liaoning’s abandoned magnesite as raw material and the coke oven gas from steelworks as fuel showed the best economic performance in terms of cost for greenhouse gas emissions.

Their findings are published in the KeAi journal Carbon Resources Conversion.

“We hope our work would provide useful insights for the sustainable development of magnesium industries and the proper route selection under the carbon peaking and carbon neutrality goals of China,” said Mr. Huang.

###

Contact the author:Xiaorui Huang, Shenyang University of Chemical Technology, [email protected]

The publisher KeAi was established by Elsevier and China Science Publishing & Media Ltd to unfold quality research globally. In 2013, our focus shifted to open access publishing. We now proudly publish more than 100 world-class, open access, English language journals, spanning all scientific disciplines. Many of these are titles we publish in partnership with prestigious societies and academic institutions, such as the National Natural Science Foundation of China (NSFC).

Journal

Carbon Resources Conversion

DOI

10.1016/j.crcon.2023.10.002

Method of Research

Case study

Subject of Research

Not applicable

Article Title

A life cycle analysis on magnesium production processes: Energy consumption, carbon emission and economics

COI Statement

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.