With all the cameras, sensors and other devices designed for driver comfort and safety, today’s cars house more than 2000 electrical connectors. And these connectors need to provide uninterrupted electrical contact no matter how cold, wet or bumpy the ride. Materials scientist Professor Frank Mücklich has developed a laser surface texturing procedure that makes the surfaces of the electrical contacts more stable and more efficient. In recognition of this work, the Saarbrücken professor has now been awarded the Albert Keil Prize by the German Association for Electrical, Electronic & Information Technologies (VDE), which is awarded for outstanding achievements in the field of electrical contacts.

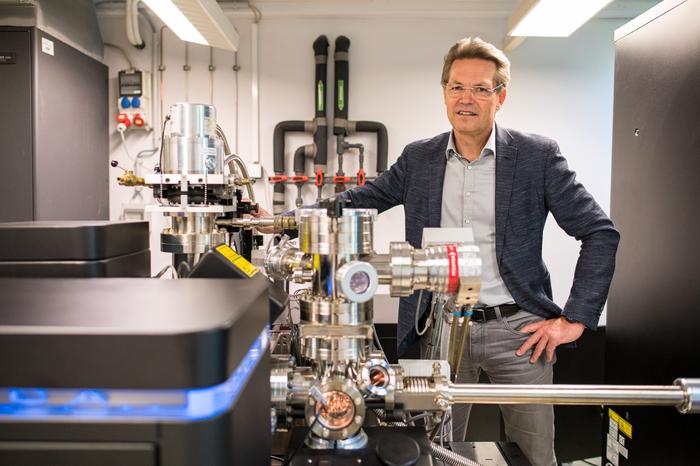

Credit: Oliver Dietze

With all the cameras, sensors and other devices designed for driver comfort and safety, today’s cars house more than 2000 electrical connectors. And these connectors need to provide uninterrupted electrical contact no matter how cold, wet or bumpy the ride. Materials scientist Professor Frank Mücklich has developed a laser surface texturing procedure that makes the surfaces of the electrical contacts more stable and more efficient. In recognition of this work, the Saarbrücken professor has now been awarded the Albert Keil Prize by the German Association for Electrical, Electronic & Information Technologies (VDE), which is awarded for outstanding achievements in the field of electrical contacts.

Most of the problems that arise in modern cars are caused by faults in the electrical system. But when a car’s electronic display system indicates a fault, it’s not usually due to a defect on a complicated circuit board, but to a faulty electrical connection, where electrical contact has been broken (sometimes for only a fraction of a second) as a result of a change in temperature or humidity or mechanical vibration. ‘The process that we have developed enables us to drastically reduce the electrical contact resistance by up to 80 percent compared with electrical contacts between conventionally engineered surfaces. Given that there are more than 2000 plug-in connectors in a medium-sized car, our procedure yields a significant increase in the vehicle’s overall functional reliability. This means that electrical signals are transmitted far more reliably even in adverse weather conditions such as high humidity or extreme heat or cold,’ said Frank Mücklich, Professor of Functional Materials at Saarland University.

The technique developed by Mücklich and his team is known as direct laser interference patterning (DLIP) and produces biomimetic, microstructured surfaces. The DLIP method uses interference patterns that are created when several laser beams spatially overlap to produce microscopically fine, symmetrical patterns on a material surface. The result is a periodic microscopic structuring of the surface at the micrometre scale, where the height of the structures created is less than the thickness of a human hair. Another key aspect of the DLIP method is that it is industrially efficient achieving speeds of up to one square metre per minute. ‘Plug connections fabricated from such precisely microstructured surfaces function more reliably, even after they have been manually opened and closed multiple times during the regular servicing that all cars are subjected to,’ explained Frank Mücklich. The researchers in Saarbrücken drew inspiration from the natural world, where surfaces with this kind of microtopographic structuring are known to exhibit special effects. Well-known examples include the lotus plant with its water-repellent leaves or the wing of a butterfly, whose shimmering iridescent colours are not due to the presence of pigments but to light interference effects.

‘We’ve been developing this new technique in close collaboration with our partners over many years and it’s now a marketable technology that can be deployed efficiently in the rapid processes of industrial mass production,’ said Mücklich, who heads the Steinbeis Material Engineering Center Saarland (MECS) – a research centre at Saarland University. To drive the industrial application of this novel technology platform, Mücklich co-founded SurFunction GmbH with like-minded partners. The Albert Keil Prize was awarded to Professor Mücklich not just for his work on DLIP, but in recognition of a number of other technologies that can also be used to meet the challenges posed by the shift to electromobility.

Using a variety of 3D analytical techniques, Frank Mücklich and his team can quantify the changes in the internal structure of a material caused, for instance, by the high current densities that arise when electrical contacts are switched. ‘We can see how the microstructure of a material changes on the micro-, nano- and atomic scale under mechanical or electrical loading. Due to the high battery capacities and fast charging speeds of modern electric vehicles (EVs), the electrical contacts and the charging infrastructure are subjected to significant electrical stresses. We can now understand quantitatively what is happening in the interior of the material during such processes, including gaining insight into how the electrical resistance of the material changes. This will facilitate the development of electrical components that are more robust and durable,’ explained Professor Mücklich. The work of Mücklich and his team is significant given the ongoing transition to more sustainable forms of energy and the strong growth in the share of EVs in the automotive market, but is perhaps of even more crucial importance for the reliability and operational safety of autonomous vehicles.

Press photographs:

Press photographs that can be used free of charge with this press release can be found at the bottom of the following web page.

https://www.uni-saarland.de/aktuell/sicherheit-elektrische-kontakte-in-autos-27777.html

Further information:

Department of Functional Materials: www.fuwe.uni-saarland.de

Steinbeis Material Engineering Center Saarland (MECS):

www.mec-s.de

SurFunction GmbH: www.surfunction.com

Questions can be addressed to:

Prof. Dr. Frank Mücklich

Department of Functional Materials, Saarland University

Steinbeis Material Engineering Center Saarland (MECS)

Tel. +49 681 302-70500

Email: [email protected]

Note for radio journalists:

Studio-quality telephone interviews can be conducted with researchers at Saarland University using broadcast audio IP codec technology (IP direct dial or via the ARD node 106813020001). Interview requests should be addressed to the university’s Press and Public Relations Office (+49 (0)681 302-3610).