SAN ANTONIO — October 17, 2023 —Southwest Research Institute (SwRI) will continue advancing the Elastic Plastic Impact Computations (EPIC) dynamic finite-element code as part of an Other Transaction Prototype Agreement with the U.S Army Corps of Engineers. The first year’s funding of $500,000 has been awarded, with optional additional funding across the next three years totaling $3.5 million.

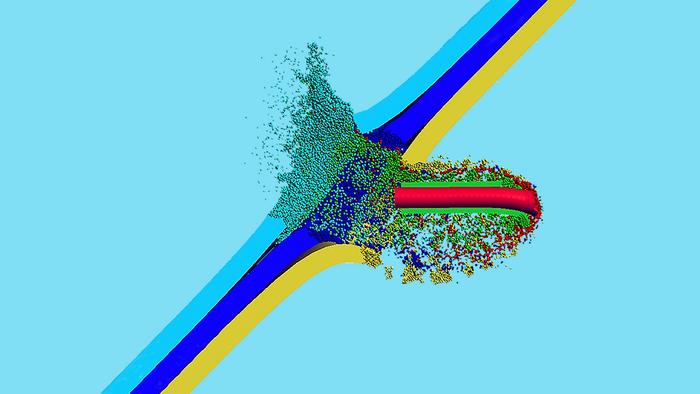

“EPIC uses finite element and particle methods to simulate complex impact and explosion scenarios,” said SwRI Staff Engineer Dr. Stephen Beissel, who leads the EPIC project and has been involved in EPIC’s development since the mid-1990s. “The numerical algorithms and the material models allow EPIC to handle highly dynamic and energetic events. Through simulations with the EPIC code, engineers can perform analyses of how a particular design for a ground vehicle, ship or aircraft component would react under stress in real-world conditions.”

The development of the EPIC code began in the 1970s to cost-effectively design warheads, body armor and armored vehicles, and to model their interactions. In 2007 the EPIC development team joined SwRI, which opened an office in Minneapolis, Minnesota to support them. At that time, SwRI took over maintenance and development of the project.

EPIC uses the finite element analysis, an efficient computational technique, to model a full range of impact scenarios, including high-speed impacts, which generate large pressures, high strain rates and permanent deformations in solid materials. It also uses particle methods, an approach similar to the finite-element method, which continuously reassesses the local regions over which information is exchanged.

“One of EPIC’s unique features is the accurate transition from finite elements to particle methods when the deformations become very large. It is an important tool for designing effective warheads, as well as effective armor for vehicles, aircraft and soldiers, and to provide protection against a wide range of threats,” Beissel said. “It simulates high-velocity impact events and, in the case of warheads, it simulates explosive detonation.”

Over the next four years, SwRI will improve and update EPIC, aiming to increase its accuracy, expand the types of problems and scenarios it is able to address, and increase its computational efficiency when used on supercomputers and GPU clusters.

“As our adversaries continue to work on new munitions, such as hypersonic missiles, we need tools to help us counter by designing new armor that can withstand them and new approaches to defeating those threats,” Beissel said. “Creating physical prototypes and testing them is expensive and time-consuming, especially in destructive events. Simulating these dynamic and explosive large-strain events, instead of constantly recreating a physical prototype, makes the design cycle more efficient and cost-effective.”

For more information, visit https://www.swri.org/industry/ballistics-explosives/epic-dynamic-finite-element-code.

Credit: Southwest Research Institute

SAN ANTONIO — October 17, 2023 —Southwest Research Institute (SwRI) will continue advancing the Elastic Plastic Impact Computations (EPIC) dynamic finite-element code as part of an Other Transaction Prototype Agreement with the U.S Army Corps of Engineers. The first year’s funding of $500,000 has been awarded, with optional additional funding across the next three years totaling $3.5 million.

“EPIC uses finite element and particle methods to simulate complex impact and explosion scenarios,” said SwRI Staff Engineer Dr. Stephen Beissel, who leads the EPIC project and has been involved in EPIC’s development since the mid-1990s. “The numerical algorithms and the material models allow EPIC to handle highly dynamic and energetic events. Through simulations with the EPIC code, engineers can perform analyses of how a particular design for a ground vehicle, ship or aircraft component would react under stress in real-world conditions.”

The development of the EPIC code began in the 1970s to cost-effectively design warheads, body armor and armored vehicles, and to model their interactions. In 2007 the EPIC development team joined SwRI, which opened an office in Minneapolis, Minnesota to support them. At that time, SwRI took over maintenance and development of the project.

EPIC uses the finite element analysis, an efficient computational technique, to model a full range of impact scenarios, including high-speed impacts, which generate large pressures, high strain rates and permanent deformations in solid materials. It also uses particle methods, an approach similar to the finite-element method, which continuously reassesses the local regions over which information is exchanged.

“One of EPIC’s unique features is the accurate transition from finite elements to particle methods when the deformations become very large. It is an important tool for designing effective warheads, as well as effective armor for vehicles, aircraft and soldiers, and to provide protection against a wide range of threats,” Beissel said. “It simulates high-velocity impact events and, in the case of warheads, it simulates explosive detonation.”

Over the next four years, SwRI will improve and update EPIC, aiming to increase its accuracy, expand the types of problems and scenarios it is able to address, and increase its computational efficiency when used on supercomputers and GPU clusters.

“As our adversaries continue to work on new munitions, such as hypersonic missiles, we need tools to help us counter by designing new armor that can withstand them and new approaches to defeating those threats,” Beissel said. “Creating physical prototypes and testing them is expensive and time-consuming, especially in destructive events. Simulating these dynamic and explosive large-strain events, instead of constantly recreating a physical prototype, makes the design cycle more efficient and cost-effective.”

For more information, visit https://www.swri.org/industry/ballistics-explosives/epic-dynamic-finite-element-code.