Hydrogen has become the beacon of clean energy owing to its high energy density and carbon-free emissions. Despite these advantages, hydrogen fuel is still far from being commercialized. Liquefying hydrogen requires a huge amount of energy and extremely low temperatures, making its large-scale production and transportation over long distances quite challenging. Fortunately, ammonia is a promising hydrogen carrier that can be easily liquified under milder conditions, transported, and decomposed with the help of a catalyst to produce pure nitrogen gas and the desired hydrogen gas.

Credit: Tokyo Tech

Hydrogen has become the beacon of clean energy owing to its high energy density and carbon-free emissions. Despite these advantages, hydrogen fuel is still far from being commercialized. Liquefying hydrogen requires a huge amount of energy and extremely low temperatures, making its large-scale production and transportation over long distances quite challenging. Fortunately, ammonia is a promising hydrogen carrier that can be easily liquified under milder conditions, transported, and decomposed with the help of a catalyst to produce pure nitrogen gas and the desired hydrogen gas.

Over the years, studies have found that basic oxide support promotes ammonia decomposition reaction in the presence of non-noble metal catalysts such as nickel (Ni) by facilitating electron donation. A similar ability to promote ammonia catalysis is seen in nitrogen-containing support materials. While the former requires high operating temperatures for catalysts, the latter is highly sensitive to air and water, which can lead to an irreversible deactivation.

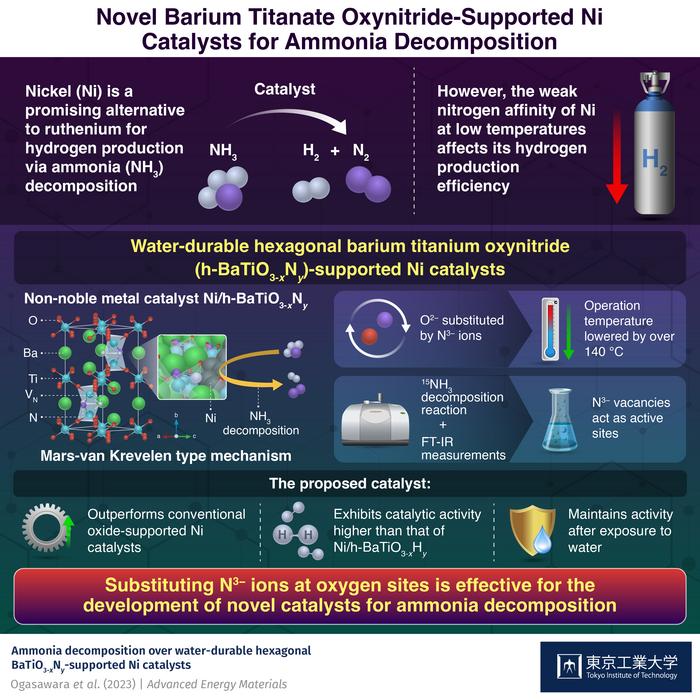

In a recent breakthrough published in Advanced Energy Materials, a team of researchers led by Professor Masaaki Kitano from Tokyo Institute of Technology (Tokyo Tech) has overcome these hurdles by developing a highly active Ni-based ammonia decomposition catalyst supported on hexagonal barium titanium oxynitride (h-BaTiO3−xNy). The new precious metal-free catalyst exhibited an excellent ammonia decomposition rate at operating temperatures lower than that required for conventional Ni-based catalysts. “Precious metals like ruthenium are commonly used as ammonia decomposition catalysts but are highly expensive. This study presents a Ni-based alternative that shows a good hydrogen production rate at low temperatures, a feat rather difficult to achieve owing to the weak affinity of nitrogen towards Ni below a certain temperature,” explains Prof. Kitano.

In their study, the team explored perovskite-type oxynitrides—a class of materials known for their stability and ability to form nitrogen vacancies. But they have not been exploited as support materials for ammonia decomposition catalysis at lower temperatures so far. Here, the researchers synthesized the new Ni/h-BaTiO3−xNy catalyst by reacting nitrogen gas and Ni/h-BaTiO3−xHy oxyhydride under mild conditions. The obtained catalyst was then subjected to ammonia decomposition experiments for analyzing its reaction rates and effectiveness. The team also carried out a series of analytical tests and mathematical calculations to understand its catalysis mechanism.

The results revealed that substituting the O2– sites on the BaTiO3 lattice with N3– ions reduced the operating temperature of the Ni-based catalyst by over 140oC, which significantly outperformed the conventional Ni-based ammonia decomposition catalysts, as well as its oxyhydride precursor. Furthermore, isotope experiments and Fourier transform-infrared spectroscopy measurements indicated that N3– vacancies act as active sites for the decomposition reaction at the metal support interface, where Ni facilitates the desorption of nitrogen gas from the support. The team also found that Ni/h-BaTiO3−xNy was stable in water, and its catalytic activity remained practically unaffected after exposure.

In effect, the study elucidates the catalysis mechanism, highlighting the significance of N3– ion substitution in promoting the catalysis of ammonia decomposition. These insights can promote the development of various highly active non-noble metal catalysts composed of nickel, cobalt, and iron. “This will aid in making the production of hydrogen fuel from ammonia more feasible, paving the way for cleaner energy and a greener planet,” concludes Prof. Kitano.

Journal

Advanced Energy Materials

DOI

10.1002/aenm.202301286

Method of Research

Experimental study

Subject of Research

Not applicable

Article Title

Ammonia decomposition over water-durable hexagonal BaTiO3−xNy-supported Ni catalysts

Article Publication Date

25-Jul-2023