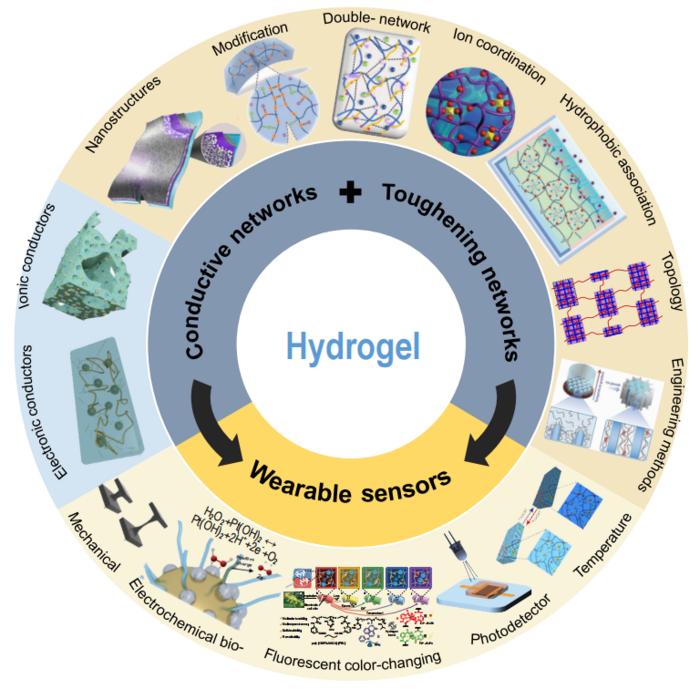

This review is written by Dr. Weixing Song from the Department of Chemistry, Capital Normal University. The paper reviewed the toughness and conductive network of existing hydrogel sensors. It emphasized the development status of various hydrogel sensors and highlighted strategies to enhance their mechanical and electrical performance. The findings are valuable for designing components and structures of high-performance wearable hydrogel sensors.

Credit: ©Science China Press

This review is written by Dr. Weixing Song from the Department of Chemistry, Capital Normal University. The paper reviewed the toughness and conductive network of existing hydrogel sensors. It emphasized the development status of various hydrogel sensors and highlighted strategies to enhance their mechanical and electrical performance. The findings are valuable for designing components and structures of high-performance wearable hydrogel sensors.

The increasing demand for healthcare IoT devices drives the development of wearable electronics. Electronic skins possess softness, stretchability, and self-healing properties, making them ideal for various applications. Hydrogels, with properties similar to human skin, have gained interest due to their flexibility and ability to accurately detect deformations. Hydrogels can also repair themselves through various reactions, offering great potential for development of hydrogel-based sensors.

The 3D network of hydrogels combines solid-like properties with efficient substance transport through aqueous phases. Toughened hydrogels, including double-network, hydrophobic associated, and composite hydrogels, are reinforced through physical or chemical cross-linking, resulting in increased ductility and toughness. This makes them suitable for integration into electronic devices that can conform to the stretching of human skin or joints. Incorporating electronic conductors or ions into hydrogels forms conductive hydrogels, enhancing conductivity and contributing to the matrix network structure. The elastic matrix and conductive component are essential in conductive hydrogels.

This paper concludes the advancement of hydrogel sensors and point outs crucial scientific and technical concerns that require additional investigation. The paper contends that an optimal hydrogel sensor should exhibit resilience in harsh environments, possess excellent resistance to moisture and expansion, demonstrate compatibility with human skin, and exhibit distinctive mechanical and electrical properties. Furthermore, it should be capable of intelligent data processing to fulfill the demands of everyday life. Despite the progress made, existing hydrogel sensors encounter challenges and necessitate ongoing research and development to achieve successful integration, packaging, and other essential technologies.

This review emphasizes the techniques aimed at enhancing the mechanical and electrical capabilities of hydrogel sensors to meet the future requirements of wearable devices. Such advancements hold the potential to expand the horizons of intelligent health monitoring, artificial intelligence, virtual reality, and contribute to the progress of human-computer interaction and artificial limbs.

###

See the article:

Pathways towards wearable and high-performance sensors based on hydrogels: toughening networks and conductive networks

https://doi.org/10.1093/nsr/nwad180

Journal

National Science Review

DOI

10.1093/nsr/nwad180