As necessary as cooling technologies are, we’re still operating on an outdated technology that can be considered a significant contributor to global warming and greenhouse gas emissions. Currently, vapor compression cycle-based cooling (VCC) is the standard for reliable cooling of air conditioning and refrigeration, but by switching to electrocaloric cooling (EC) researchers are hoping to create a more environmentally friendly, scalable and compressor-free method of cooling to benefit businesses, families and the environment.

Credit: Q.M. Zhang, Tsinghua University

As necessary as cooling technologies are, we’re still operating on an outdated technology that can be considered a significant contributor to global warming and greenhouse gas emissions. Currently, vapor compression cycle-based cooling (VCC) is the standard for reliable cooling of air conditioning and refrigeration, but by switching to electrocaloric cooling (EC) researchers are hoping to create a more environmentally friendly, scalable and compressor-free method of cooling to benefit businesses, families and the environment.

The researchers published their work in iEnergy on June 29. The study highlights the electrocaloric effect (ECE) and how it can work to produce a cleaner, high-efficiency way of cooling without all of the harmful greenhouse gas emissions that a standard VCC process would add to the atmosphere.

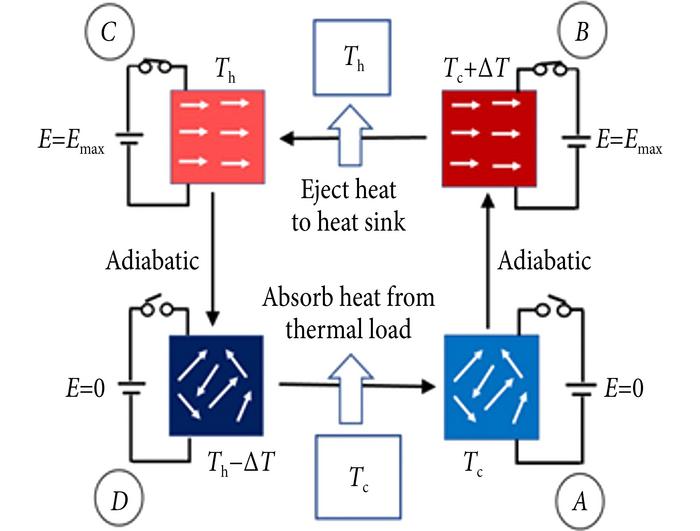

The ECE can be explained as a reversible change of a dielectric material when it’s been exposed to a controlled change in the applied electric field. A dielectric material, like ceramic which is used in this study, poorly conducts electricity but supports electrostatic fields, which is the catalyst for changing the polarization, or charge, of a field to induce the desired results of cooling. The reversible nature of this change allows for heat distribution and cooling to occur.

In order to have a large ECE the change in entropy needs to be sufficiently large, too. Entropy can be quantified as thermal energy that is ready to be made useful by converting it into mechanical work. This is where ferroelectric materials become advantageous to use. To have a high-efficiency product, the desired “operating window” where the largest change in the electrostatic field can be achieved, is just above the ferroelectric-paraelectric phase transition. Essentially, this transition phase consists of two oppositely “charged” polarized fields, yielding the large change in entropy, or disorder, needed.

“These EC materials and device research reveals the promise of ferroelectric materials in generating giant ECE at low electric fields and EC cooling devices achieving high performance,” said Q.M. Zhang, first author and researcher of the study.

Simply put, the EC material used is heated past the temperature of the heat sink, and when the two materials make contact, a temperature equilibrium is reached; this is achieved by putting the energy into the field around the objects, not the objects themselves. By using ferroelectric materials a large ECE can be seen under relatively low electric fields which can achieve a compressor-free system, lending to a cooling device that can be much more scalable to meet the needs of families and businesses alike.

“The electrocaloric cooling is attractive as an alternative to the VCC cooling. EC cooling is environmentally benign, compressor-free, highly scalable, and has the potential of achieving higher efficiency than VCC cooling” Zhang said.

While EC cooling is still being developed and researched as a practical way of cooling, a large portion of work that can be done on the EC coolers is developing lead-free materials, as currently the best-performing EC ceramics are lead-based. The lead-based ferroelectrics generate a higher amount of cooling in a shorter amount of time, but lead is a toxic substance, and generally, its use will not be well received by the public.

Another goal is to improve the thermal conductivity of the EC coolers. Since using lead isn’t the optimal choice, the performance of the ferroelectric component ideally would be improved to reduce heat loss and increase operating power. Achieving these goals and developing EC coolers that can be utilized in commercial and residential areas might aid in the global efforts to reduce greenhouse gas emissions and move forward with cleaner cooling technology.

Xin Chen of the Department of Materials Science and Engineering and the Materials Research Institute at Pennsylvania State University, Wenyi Zhu and Q.M. Zhang of the Materials Research Institute and Department of Electrical Engineering at Pennsylvania State University contribute to this research.

The U.S. Office of Naval Research supported this research.

##

About iEnergy

iEnergy (Published by Tsinghua University Press), has multiple meanings, intelligent energy, innovation for energy, internet of energy, and electrical energy due to “i” is the symbol of current. iEnergy, publishing quarterly, is a cross disciplinary journal aimed at disseminating frontiers of technologies and solutions of power and energy. The journal publishes original research on exploring all aspects of power and energy, including any kind of technologies and applications from power generation, transmission, distribution, to conversion, utilization, and storage. iEnergy provides a platform for delivering cutting-edge advancements of sciences and technologies for the future-generation power and energy systems.

About Tsinghua University Press

Established in 1980, belonging to Tsinghua University, Tsinghua University Press (TUP) is a leading comprehensive higher education and professional publisher in China. Committed to building a top-level global cultural brand, after 42 years of development, TUP has established an outstanding managerial system and enterprise structure, and delivered multimedia and multi-dimensional publications covering books, audio, video, electronic products, journals and digital publications. In addition, TUP actively carries out its strategic transformation from educational publishing to content development and service for teaching & learning and was named First-class National Publisher for achieving remarkable results.

Journal

iEnergy

DOI

10.23919/IEN.2023.0012

Article Title

Electrocaloric cooling technologies for a sustainable world

Article Publication Date

29-Jun-2023