Since the interaction between the abrasive grain, workpiece and nanofluids on the minimum quantity lubrication (MQL) grinding interface are difficult to observe directly, there is still lack of direct evidence to reveal the internal mechanism of carbon group nanoparticles on the abrasive grain/workpiece grinding interface. Concerning this issue, the professor Changhe Li team, from department of Mechanical and Automotive Engineering of Qingdao University of Technology, China, using molecular dynamics simulation to study the tribological mechanism of friction-reducing and anti-wear of three kinds of carbon group nanoparticles, i.e., diamond, carbon nanotubes and graphene. This research will disclose the formation mechanism of the lubrication film on the grinding interface under MQL condition. Based on this, the tribological behaviors of the nanoparticles on the interface will be further investigated. It will provide direct evidence for revealing the effect mechanism of carbon group nanoparticles on the grinding interface. This study can be found in the journal Frontiers of Mechanical Engineering on 26 April, 2023.

Credit: HIGHER EDUCATION PRESS LIMITED COMPANY

Since the interaction between the abrasive grain, workpiece and nanofluids on the minimum quantity lubrication (MQL) grinding interface are difficult to observe directly, there is still lack of direct evidence to reveal the internal mechanism of carbon group nanoparticles on the abrasive grain/workpiece grinding interface. Concerning this issue, the professor Changhe Li team, from department of Mechanical and Automotive Engineering of Qingdao University of Technology, China, using molecular dynamics simulation to study the tribological mechanism of friction-reducing and anti-wear of three kinds of carbon group nanoparticles, i.e., diamond, carbon nanotubes and graphene. This research will disclose the formation mechanism of the lubrication film on the grinding interface under MQL condition. Based on this, the tribological behaviors of the nanoparticles on the interface will be further investigated. It will provide direct evidence for revealing the effect mechanism of carbon group nanoparticles on the grinding interface. This study can be found in the journal Frontiers of Mechanical Engineering on 26 April, 2023.

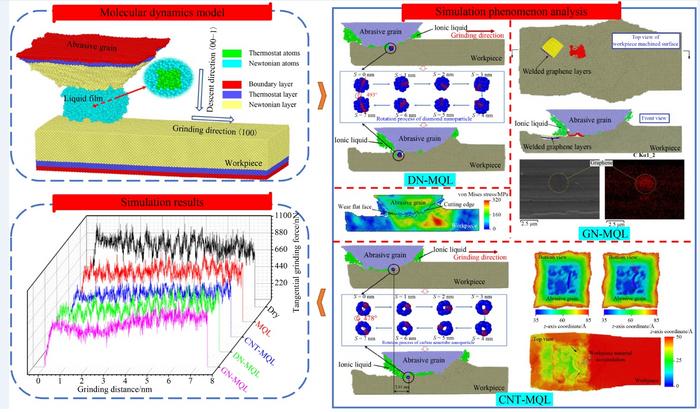

Carbon group nanofluids can further improve the friction-reducing and anti-wear properties of MQL. However, the formation mechanism of the lubrication film generated by carbon group nanofluids on the MQL grinding interface is not fully revealed due to lack of sufficient evidences. In this paper, molecular dynamics simulations are performed to explore the interactions on the abrasive grain/workpiece grinding interface, so as to reveal the formation mechanism of the lubrication film. Three representative kinds of carbon group nanoparticles, i.e., nano-diamond, carbon nanotube and graphene nanosheet, are taken as research targets, and [BMIM]BF4 ionic liquid is used as the base fluid of nanofluids. The research firstly discloses the formation mechanism of the lubrication film under the MQL condition using the ionic liquid only. Based on this, the tribological behaviors of the nanoparticles on the grinding interface are further investigated, so as to reveal the tribological mechanism of carbon group nanofluids on the grinding interface.

The investigation show that boundary lubrication film is formed on the grinding interface under MQL condition, via the ionic liquid molecules absorbing in the groove-like fractures on the grain wear flat face. The boundary lubrication film takes effect of friction-reduction through reducing the abrasive grain/workpiece contact area. Under nanofluid MQL conditions, carbon group nanoparticles further enhance the tribological performances of the MQL technique benefitting from their corresponding tribological behaviors on the grinding interface. The behaviors involve the rolling effect of nano-diamond, the rolling and sliding effects of carbon nanotube, and the interlayer shear effect of graphene nanosheet. Compared with the MQL condition, the tangential grinding forces are further reduced by 8.5%, 12.0%, and 14.1% under the diamond, carbon nanotube, and graphene nanofluid MQL conditions, respectively. This provides direct evidence for the effect mechanism of carbon group nanoparticles on the abrasive grain/workpiece grinding interface.

###

Reference: Dexiang WANG, Yu ZHANG, Qiliang ZHAO, Jingliang JIANG, Guoliang LIU, Changhe LI. Tribological mechanism of carbon group nanofluids on grinding interface under minimum quantity lubrication based on molecular dynamics simulation. Frontiers of Mechanical Engineering, 2023, 18(1): 17 https://doi.org/10.1007/s11465-022-0733-z

About Frontiers of Mechanical Engineering

Frontiers of Mechanical Engineering is an international peer-reviewed academic journal sponsored by the Ministry of Education of China. The journal seeks to provide a forum for a broad blend of high-quality academic papers in order to promote rapid communication and exchange between researchers, scientists, and engineers in the field of mechanical engineering. The journal publishes original research articles, review articles and feature articles. The journal covers all major branches of mechanical engineering including (not limited to): machines and mechanisms, gears and transmissions, mechanical system dynamics, mechanical structures and stress analysis, tribology and surface technology, mechanical design and bionics, machining processes and technologies, manufacturing automation, precision engineering, mechatronics and embedded systems, micro/nano manufacturing and systems, robotics, sensing, MEMS, and green manufacturing.

The Editors-in-Chief are Academician Zheng You from Huazhong University of Science and Technology, China, Academician Dongming Guo from Dalian University of Technology, China. The journal has been indexed by SCI, SCOPUS, INSPEC, Astrophysics Data System (ADS), Google Scholar, CSA, Academic OneFile, Chinese Science Citation Database, Expanded Academic, Gale, OCLC, Summon by ProQuest, etc.

About Higher Education Press

Founded in May 1954, Higher Education Press Limited Company (HEP), affiliated with the Ministry of Education, is one of the earliest institutions committed to educational publishing after the establishment of P. R. China in 1949. After striving for six decades, HEP has developed into a major comprehensive publisher, with products in various forms and at different levels. Both for import and export, HEP has been striving to fill in the gap of domestic and foreign markets and meet the demand of global customers by collaborating with more than 200 partners throughout the world and selling products and services in 32 languages globally. Now, HEP ranks among China’s top publishers in terms of copyright export volume and the world’s top 50 largest publishing enterprises in terms of comprehensive strength.

The Frontiers Journals series published by HEP includes 28 English academic journals, covering the largest academic fields in China at present. Among the series, 12 have been indexed by SCI, 6 by EI, 2 by MEDLINE, 1 by A&HCI. HEP’s academic monographs have won about 300 different kinds of publishing funds and awards both at home and abroad.

Journal

Frontiers of Mechanical Engineering

DOI

10.1007/s11465-022-0733-z

Method of Research

Computational simulation/modeling

Subject of Research

Not applicable

Article Title

Tribological mechanism of carbon group nanofluids on grinding interface under minimum quantity lubrication based on molecular dynamic simulation

Article Publication Date

26-Apr-2023