In biomedical technology, tissue engineering for the ex-vivo production of skin or organs is becoming increasingly important. This requires biocompatible microfibres with enclosed microcapsules of controlled size and shape, as the cells used for tissue engineering must be embedded in material that is as similar as possible to the natural arrangement in vivo. Until now, the production of such fibres at low output has been quite costly and time-consuming. Researchers at Graz University of Technology (TU Graz) have now developed a new method for producing microfibres with the desired properties that can be used in pharmaceuticals and biomedicine, and which provides significantly higher yields than previous methods while requiring much less production effort.

Credit: David Baumgartner, Francesco Marangon – TU Graz

In biomedical technology, tissue engineering for the ex-vivo production of skin or organs is becoming increasingly important. This requires biocompatible microfibres with enclosed microcapsules of controlled size and shape, as the cells used for tissue engineering must be embedded in material that is as similar as possible to the natural arrangement in vivo. Until now, the production of such fibres at low output has been quite costly and time-consuming. Researchers at Graz University of Technology (TU Graz) have now developed a new method for producing microfibres with the desired properties that can be used in pharmaceuticals and biomedicine, and which provides significantly higher yields than previous methods while requiring much less production effort.

In a paper published by the American Physical Society, Carole Planchette and her team from the Institute of Fluid Mechanics and Heat Transfer at TU Graz explain how their development, funded by the Austrian Science Fund FWF and the Austria Wirtschaftsservice Gesellschaft aws, can produce several metres of this microfibre in seconds. The current methods manage at most a few centimetres in the same period of time. This acceleration has been made possible by moving away from the production of microfibres in a liquid environment using microfluidic chips to a production that is possible in sterile room air. As a result, the necessary process steps as well as the costs could be greatly reduced and potential sources of errors and blockages minimised.

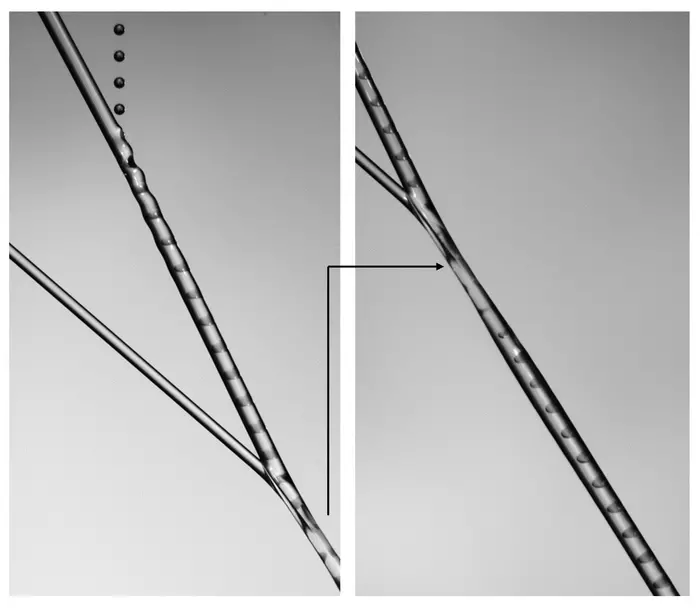

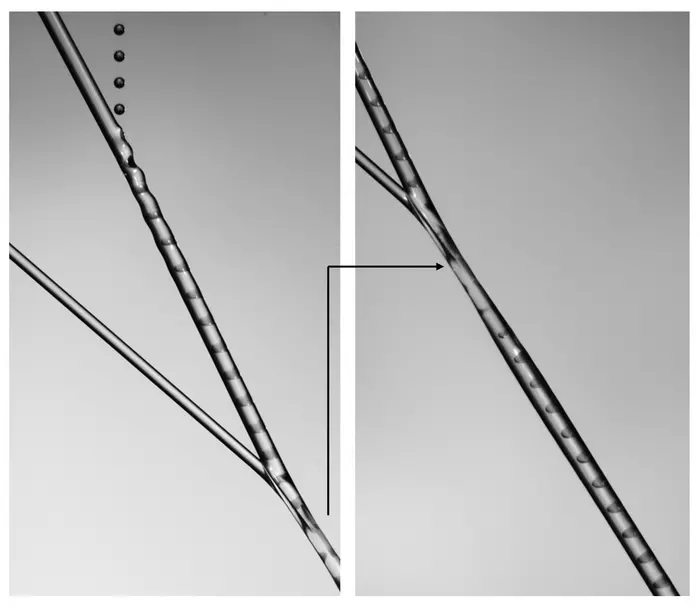

Droplets meet liquid jet

In the method now presented, a regular stream of droplets containing cells or active substances is combined with a liquid jet of aqueous alginic acid solution. The alginic acid obtained from brown algae forms upon contact with calcium cations an elastic hydrogel called alginate – similarly to the process commonly used in the molecular cuisine to form caviar pearls. This hydrogel is on the one hand fully biocompatible and on the other hand prevents the embedded droplets from coalescing together. Therefore, to cure the alginic acid solution stream, a second stream with calcium cations is jetted continuously on top. The resulting fibre, which can be grown at up to 5 metres per second, can then simply be collected on a turntable. All these steps take place in the air and not in liquid microfluidic production as before.

In a couple of years, it should be possible to produce a fiber assembly mimicking the skin from human cells using the new method. This integration of cells into the microfiber is the next step for Carole Planchette and her team. The expected result could be, for example, a great help for burn victims, as new and personalized skin for transplantation could be produced from their own intact skin cells in a very short time. In this perspective, researchers at TU Graz are working together with the Medical University of Graz on research into the production of artificial skin. Looking much further into the future, certainly more than ten years, one day it may also be possible to produce artificial organs using this microfibre.

Replacement for animal testing

In addition to tissue engineering, the new and faster production method opens up other areas of application for the biocompatible microfibre, such as cell screening. In the near future, it will be possible to test new molecules for medical agents much more extensively on cells to determine whether or at what point they are toxic. Due to the large fibre length available as a result of rapid production, different temperatures or concentrations could be tested along the fibre in a single run. For such tests on a large scale, animal experiments have been used up to now, and this could be largely avoided.

The important role of basic research

“For me, it is particularly interesting when I can use fundamental aspects of fluid mechanics to find new and innovative solutions to previously unsolved problems,” explains Carole Planchette. “This allows us to discover pathways to new applications and our manufacturing method of biocompatible microfibres with regular inclusions at high output and low cost demonstrates this. The possibilities for cell screening, tissue construction and eventually organ production that this opens up can be of great benefit to many disciplines. For me, this is also a clear sign of how important the role of basic and multidisciplinary research is, thereby creating the fundament for ground-breaking applications.”

Journal

Physical Review Applied

DOI

10.1103/PhysRevApplied.19.054006

Method of Research

Experimental study

Subject of Research

Lab-produced tissue samples

Article Title

In-Air Microfluidic Strategy for the Production of Sodium Alginate Fibers with Regular Inclusions at Very High Throughput

Article Publication Date

2-May-2023