Electrocatalysis as an efficient energy storage and conversion technology opens up a new path to solve the existing problems of energy depletion and environmental pollution caused by fossil fuel consumption. Metal-organic frameworks (MOFs), a class of crystalline porous materials with high specific surface area, high porosity, and designable structure, have shown great potential as new electrocatalysts. However, the inherent low electrical conductivity and low stability of MOFs have greatly hindered their further application in electrocatalysis.

Credit: Xian-He Bu and Jiandong Pang, Nankai University

Electrocatalysis as an efficient energy storage and conversion technology opens up a new path to solve the existing problems of energy depletion and environmental pollution caused by fossil fuel consumption. Metal-organic frameworks (MOFs), a class of crystalline porous materials with high specific surface area, high porosity, and designable structure, have shown great potential as new electrocatalysts. However, the inherent low electrical conductivity and low stability of MOFs have greatly hindered their further application in electrocatalysis.

How to design and synthesize highly stable and conductive MOFs materials, and regulate the energy of MOFs electrocatalytic reaction intermediates and the adsorption strength of active species are the keys to enhancing the electrocatalytic performance. Based on the above ideas, a large number of MOFs-based electrocatalysts have been newly reported in recent years. Therefore, it is necessary to provide a timely summary of the latest progress. Li et al. published their review on Jan. 24 2023 in Industrial Chemistry & Materials.

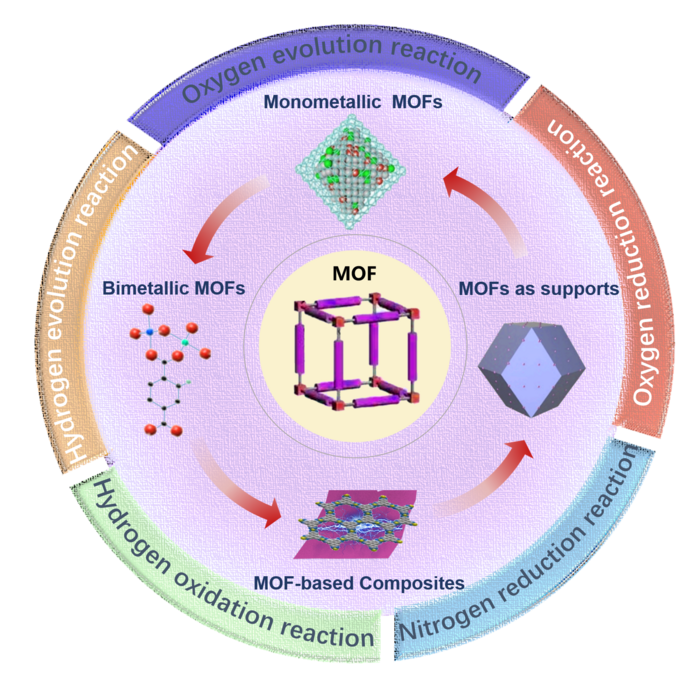

“The development of efficient, green, and low-cost metal-organic frameworks (MOFs)-based electrocatalysts is crucial to address the existing energy depletion and environmental pollution problems caused by fossil fuel consumption.” said Jiandong Pang, a professor at Nankai University. “In this review, we systematically summarized the research progress on the application of MOFs materials in electrocatalytic hydrogen evolution reactions (HER), hydrogen oxidation reactions (HOR), oxygen evolution reactions (OER), oxygen reduction reactions (ORR), and nitrogen reduction reactions (NRR) according to the categories of monometallic MOFs, bimetallic MOFs, MOF-based composites and MOFs as supports, thus revealing the structure-property relationships. Strategies to enhance the stability and conductivity of MOFs-based electrocatalytic materials are also summarized. We also provided an outlook on the opportunities and challenges facing MOFs in electrocatalysis and list the problems that need to be explored and solved.”

As a new type of crystalline porous material, MOFs are known for their various predictable and designable structures, high surface area, guest-accessible voids, and easily functionalized channels. MOFs materials are currently used in a wide range of different electrocatalytic reactions, including HER, HOR, ORR, and OER. These reactions are at the heart of the following devices or cells: metal air cells, renewable fuel cells, electrolytic water to hydrogen devices, and other important electrochemical energy conversion devices. Furthermore, the electrocatalytic reduction of nitrogen to ammonia also shows attractive applications in the field of energy conversion. Despite the many unique advantages of the above electrocatalytic reactions, their cost must be carefully considered in order to achieve commercialization. Therefore, it is essential and urgent to design green, low energy consuming, and highly stable MOFs electrocatalysts from both efficiency and cost perspectives.

“The synthesis of MOFs with predictable structures and high stability has been an important goal in the field of MOF research. A clear strategy to guide the design of ligands and metals will help to develop novel functionalized MOFs and provide a fire-new reference for various fields,” Pang said. “Synthesis with the same reactants may lead to MOFs with different topologies and properties, and the reaction time, method, and temperature of synthesis will also affect the crystal structure, morphology, and pore environment of MOFs, which will further affect the performance of the materials. There are two common adjustment directions for the synthesis of MOF-based electrocatalysts, i.e., tuning the size of MOFs and modulating the conductivity of MOFs.”

“Furthermore, based on the diversity of metal ions and ligands, specific metal centers and ligands containing specific organic functional groups can be selected to design and synthesize MOFs with high stability under catalytic environment and applied to the study of electrocatalysis. To make MOFs with high stability, researchers generally choose to construct frameworks using carboxylate-based ligands (hard Lewis bases) and high-valent metal ions (hard Lewis acids, such as Al3+, Cr3+, Fe3+, Ti4+, and Zr4+) or azo-based ligands (soft Lewis bases) and low-valent transition metal ions (soft Lewis acids, such as Co2+, Ni2+, Cu2+, and Zn2+) based on hard-soft-acid-base (HSAB) theory. The designed MOF possesses high stability and will greatly enhance its electrocatalytic performance.” said Xian-He Bu, a professor at Nankai University.

Pang said that there is still great scope for optimizing MOFs materials for future electrocatalytic designs. Incorporating catalytically active ligands (e.g. porphyrins) into MOFs and modulating the catalytic effect by adjusting the pore environment and pore structure is an effective strategy to enhance electrocatalytic performance. In addition, the formation of MOFs with bimetallic active sites using binuclear metal clusters/ions to optimize the electronic structure and surface state of the metal centers is also a feasible strategy. To maximize the benefits of MOFs, the use of MOFs as supports for loading metal nanoparticles or metal monoatoms and the compounding of MOFs with inorganic active materials are also suggested strategies.

“In this review, our main goal is to provide readers with timely and accurate updates on the latest research advances and electrocatalytic performance enhancement strategies in the field, while providing an outlook for future developments in the field,” Bu said.

Industrial Chemistry & Materials is a peer-reviewed interdisciplinary academic journal published by Royal Society of Chemistry (RSC) with APCs currently waived. Icm publishes significant innovative research and major technological breakthroughs in all aspects of industrial chemistry and materials, especially the important innovation of the low-carbon chemical industry, energy, and functional materials.

Journal

Industrial Chemistry and Materials

DOI

10.1039/D2IM00063F

Method of Research

Literature review

Subject of Research

Not applicable

Article Title

Recent progress in metal–organic frameworks (MOFs) for electrocatalysis

Article Publication Date

24-Jan-2023