Soft, wearable sensors can improve our lives, but these soft and stretchable electronic devices are nearly impossible to recycle. As a result, this electronic waste usually ends up in landfills or polluting the environment. Polymer scientists from the University of Groningen have developed a starch-based polymer that makes it possible to create a fully biodegradable soft material for sensors. They published a paper on this new material in ACS Applied Materials & Interfaces on 13 December.

Credit: Xiaohong Lan, University of Groningen

Soft, wearable sensors can improve our lives, but these soft and stretchable electronic devices are nearly impossible to recycle. As a result, this electronic waste usually ends up in landfills or polluting the environment. Polymer scientists from the University of Groningen have developed a starch-based polymer that makes it possible to create a fully biodegradable soft material for sensors. They published a paper on this new material in ACS Applied Materials & Interfaces on 13 December.

Soft, stretchable polymers are used to make various kinds of electronic devices. They are used for example in smart watches to make contact with the skin. Sensors in shoes or clothing are also often based on these materials, as is the screen of your smartphone. ‘These soft materials are often made from mixtures of polymers, which are difficult to purify. As a result, they are dumped in landfills, often with the toxic metal components of the sensor still present. This kind of electronic waste is becoming a serious problem’, says Xiaohong Lan, first author of the paper and postdoc at the University of Groningen Polymer Science group led by Professor Katja Loos.

Backbone

Lan, Loos, and their colleagues have developed an alternative to these complex polymers: a biodegradable material that decomposes in a matter of weeks to a few months. ‘There are easy ways to remove the metal and polymers from the e-waste’, says Lan. ‘Of course, you could try to recycle the soft polymers, but that is often too complex, and therefore too expensive.’ The researchers’ new polymer decomposes, leaving only water and carbon dioxide behind.

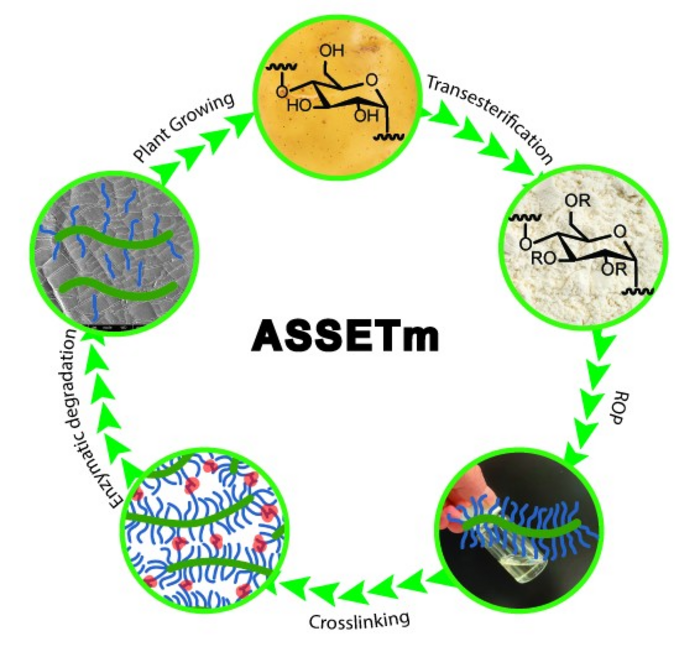

‘To create a biodegradable polymer, we started out with a backbone of starch-derived dextrin carbohydrates,’ explains Lan. ‘Most polymer backbones contain chemical bonds, which are very strong. The dextrin backbone can be degraded by natural enzymes that are present in soil.’ Long fatty acid tails were added to the dextrin in the backbone, and the researchers were able to use the amount of fatty acids added per glucose unit to regulate the hydrophobicity of the polymer. ‘The enzymes that degrade the polymer require water, so if a material is too hydrophobic, they cannot do it. If the polymer is too hydrophilic, on the other hand, the material will not have the right properties.’

Brushes

The material needs to be soft and stretchable, but also dielectric, which means that the sensors can charge themselves with the electricity created by rubbing against fabric. Apart from the fatty acid tail, the modified dextrin polymer was also grafted with lactone monomers in a brush-like pattern. These brushes give the material its stretchability. The resulting ‘Advanced Scalable Supersoft Elastic Transparent material’ (ASSETm) has all the right properties. Experiments revealed that it is suited to seal in electrodes to produce sensors. ‘We compared our sensors with state-of-the-art commercial sensors, and found that ours worked at least as well,’ says Lan.

The production process is scalable, so there is no reason why this biodegradable ASSETm should not replace traditional soft polymers in smart electronics. Lan: ‘However, we do have to change our attitude towards starch, which is usually seen as a food product.’ Currently, approximately 60% of all starch is used in animal feed, 30% for human consumption, and 10% in medical applications. ‘However, starch consumption is decreasing, and there is a downward trend in cattle numbers.’

Discussion

Group leader Katja Loos is also enthusiastic about the new material: ‘We hope that our paper will launch a discussion on further curbing e-waste. This degradable polymer can really help reduce the amount of e-waste.’

Reference: Xiaohong Lan, Wenjian Li, Chongnan Ye, Laura Boetje, Théophile Pelras, Fitrilia Silvianti, Qi Chen, Yutao Pei, and Katja Loos: Scalable and Degradable Dextrin-Based Elastomers for Wearable Touch Sensing. ACS Applied Materials & Interfaces, 13 December 2022

Journal

ACS Applied Materials & Interfaces

DOI

10.1021/acsami.2c15634

Method of Research

Experimental study

Subject of Research

Not applicable

Article Title

Scalable and Degradable Dextrin-Based Elastomers for Wearable Touch Sensing

Article Publication Date

13-Dec-2022

COI Statement

none