A highly flammable industrial gas can be stored and released more safely and efficiently using cylinders containing porous coordination polymers (PCPs), also known as metal organic frameworks (MOFs). Scientists at Japan’s Institute for Integrated Cell-Material Sciences (iCeMS) and Air Liquide Innovation Campus Tokyo developed the gas storage material and reported their results in the journal Nature Chemistry.

Acetylene is used in a wide range of industrial processes, including welding, metal cutting and organic chemical synthesis. It is highly flammable at room temperature and will spontaneously combust when the pressure rises above 2 bar, which is less than the pressure in a typical car tire.

“Acetylene storage is problematic, as it needs to be done within pressure and temperature ranges that keep it from exploding,” explains iCeMS materials chemist Ken-ichi Otake.

Currently, acetylene is stored inside cylinders dissolved in solvents like acetone. Although this makes it possible to store acetylene at high pressures, this solvent-dependent process can contaminate the gas. Still, it is not economically feasible to store and transport pure acetylene at lower, safe pressures.

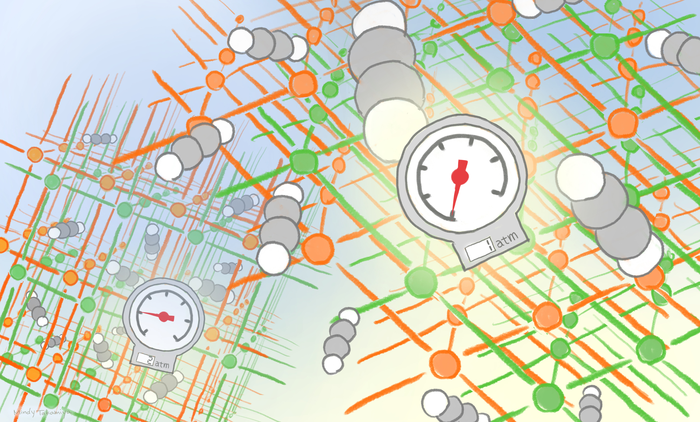

iCeMS chemist Susumu Kitagawa, Otake and their colleagues in Japan and France evaluated zinc-based MOFs for their ability to safely store and release acetylene. MOFs are porous materials made from metal ions surrounded by organic linker molecules. Acetylene is adsorbed onto the porous sites of the MOF, allowing the gas molecules to be densely stored at low pressure. The researchers prepared zinc-based structures containing benzenedicaroxylate and bypyridine linkers and modified them with amino or nitro functional groups. These functional group modifications are applied in a controlled manner to regulate the pressure needed to introduce the gas and the pressure at which the gas is released for use. This control allows researchers to predictively design a material fit for the release and use of acetylene in pre-determined working pressure ranges.

The researchers found that their flexible MOFs can store large quantities of acetylene at pressures below 2 bar, without requiring a solvent. They demonstrated acetylene release at ambient pressure using a small prototype vessel under realistic conditions. The material with the amino functional groups was particularly good, as it could release 77% of the stored gas at atmospheric pressure.

“Our findings suggest acetylene could be stored in smaller cylinders at low pressure and in larger quantities, up to 37 times more than other solvent-free storage solutions,” says Otake.

Additionally, the researchers found they could tune the material’s flexibility with the functional groups in a way that might make different variations suitable for storing the gas in different conditions and temperatures, adapting their MOF to the final usage. They plan to develop similar pressure-gated MOFs for storing other gases, like carbon dioxide, oxygen and methane.

Credit: Mindy Takamiya/Kyoto University iCeMS

A highly flammable industrial gas can be stored and released more safely and efficiently using cylinders containing porous coordination polymers (PCPs), also known as metal organic frameworks (MOFs). Scientists at Japan’s Institute for Integrated Cell-Material Sciences (iCeMS) and Air Liquide Innovation Campus Tokyo developed the gas storage material and reported their results in the journal Nature Chemistry.

Acetylene is used in a wide range of industrial processes, including welding, metal cutting and organic chemical synthesis. It is highly flammable at room temperature and will spontaneously combust when the pressure rises above 2 bar, which is less than the pressure in a typical car tire.

“Acetylene storage is problematic, as it needs to be done within pressure and temperature ranges that keep it from exploding,” explains iCeMS materials chemist Ken-ichi Otake.

Currently, acetylene is stored inside cylinders dissolved in solvents like acetone. Although this makes it possible to store acetylene at high pressures, this solvent-dependent process can contaminate the gas. Still, it is not economically feasible to store and transport pure acetylene at lower, safe pressures.

iCeMS chemist Susumu Kitagawa, Otake and their colleagues in Japan and France evaluated zinc-based MOFs for their ability to safely store and release acetylene. MOFs are porous materials made from metal ions surrounded by organic linker molecules. Acetylene is adsorbed onto the porous sites of the MOF, allowing the gas molecules to be densely stored at low pressure. The researchers prepared zinc-based structures containing benzenedicaroxylate and bypyridine linkers and modified them with amino or nitro functional groups. These functional group modifications are applied in a controlled manner to regulate the pressure needed to introduce the gas and the pressure at which the gas is released for use. This control allows researchers to predictively design a material fit for the release and use of acetylene in pre-determined working pressure ranges.

The researchers found that their flexible MOFs can store large quantities of acetylene at pressures below 2 bar, without requiring a solvent. They demonstrated acetylene release at ambient pressure using a small prototype vessel under realistic conditions. The material with the amino functional groups was particularly good, as it could release 77% of the stored gas at atmospheric pressure.

“Our findings suggest acetylene could be stored in smaller cylinders at low pressure and in larger quantities, up to 37 times more than other solvent-free storage solutions,” says Otake.

Additionally, the researchers found they could tune the material’s flexibility with the functional groups in a way that might make different variations suitable for storing the gas in different conditions and temperatures, adapting their MOF to the final usage. They plan to develop similar pressure-gated MOFs for storing other gases, like carbon dioxide, oxygen and methane.

###

DOI:

https://doi.org/10.1038/s41557-022-00928-x

About Kyoto University’s Institute for Integrated Cell-Material Sciences (iCeMS):

At iCeMS, our mission is to explore the secrets of life by creating compounds to control cells, and further down the road to create life-inspired materials.

https://www.icems.kyoto-u.ac.jp/

For more information, contact:

I. Mindy Takamiya/Christopher Monahan

[email protected]

Journal

Nature Chemistry

DOI

10.1038/s41557-022-00928-x

Article Title

Tunable acetylene sorption by flexible catenated metal–organic frameworks

Article Publication Date

21-Apr-2022