As the average life expectancy of residents increases, there are more and more cases of human bone tissue disease. With the upgrading of treatment methods, more and more bone tissue lesions can be treated with artificial implants for replacement. Due to the huge demand in the field of biophysical therapy, biomedical materials have very broad market prospects. In the past 10 years, the market growth rate of biomedical materials has remained at 20-25%, and the world population is nearly 6.5 billion. Statistics show that there are close to 400 million disabled people, 60 million physically disabled, and about 2 billion dental patients.

At present, there are only 35 million implanters of biomaterial devices, and the annual joint replacement volume is about 1.5 million, which is far from the actual number of replacements. Therefore, the market demand for biomedical materials has great potential. At present, common metal materials such as 316 stainless steel, pure titanium, TC4, cobalt-based alloys and precious metals are widely used in the production of human implants, such as dentures, bone plates, joints.

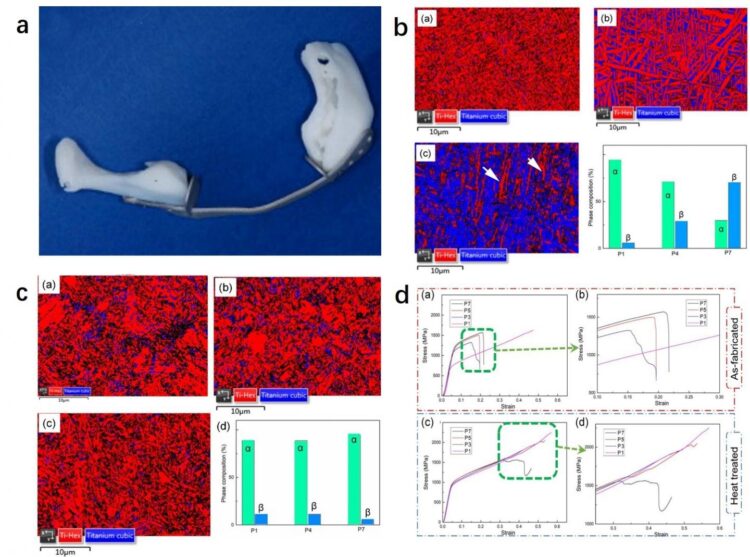

However, the elastic modulus of the above-mentioned materials is far greater than the Young’s modulus of the human bone, and the mismatch between the Young’s modulus of the metal implant and the human bone will cause physical discomfort. Therefore, it is necessary to develop an implant material with good biocompatibility, low toxicity or even non-toxicity, resistance to friction and wear, corrosion resistance, and mechanical properties that match human bones. Titanium-molybdenum alloy is the preferred choice for human implants due to its non-toxicity and low elastic modulus. As an emerging manufacturing technology, additive manufacturing technology (3D printing) is very suitable for the manufacture of parts with complex shapes, and also very suitable for the preparation of customized human implants. However, the titanium-molybdenum alloy implants directly prepared by laser three-dimensional forming technology have poor uniformity in microstructure and performance.

In the Light: Advanced Manufacturing magazine, some scientists from the State Key Laboratory of Coagulation Technology of Northwestern Polytechnical University proposed a way to control the uniformity of microstructure and performance through a heat treatment system, so that the tissue performance of 3D printed human implants and human bones can be achieved. Better matching and better biocompatibility. Aiming at the problem of poor uniformity of tissue properties of directly using 3D printed Ti-Mo alloy human implants, these scientists proposed a new type of triple-cycle heat treatment system, based on the transformation of the heat treatment process, through long-term heat preservation and extraordinary low cooling rate, the non-equilibrium metastable β phase transforms into the equilibrium α phase, which makes the structure of Ti-Mo alloy sample from top to bottom tend to be thermodynamically stable. The change of microstructure improves the mechanical properties of Ti-Mo alloy while maintaining good stability.

Through triple-cycle heat treatment, the microstructure and performance of the 3D printed Ti-Mo alloy are adjusted and controlled, so that the 3D printed Ti-Mo alloy human implant has better microstructure and performance stability, and thus better matches the performance of human bones. This makes 3D printed Ti-Mo alloy human implants more widely used in the biomedical field.

###

Media Contact

Nan Kang

[email protected]

Related Journal Article

http://dx.