Credit: by Hongxing Dong, Wei Xie, Long Zhang

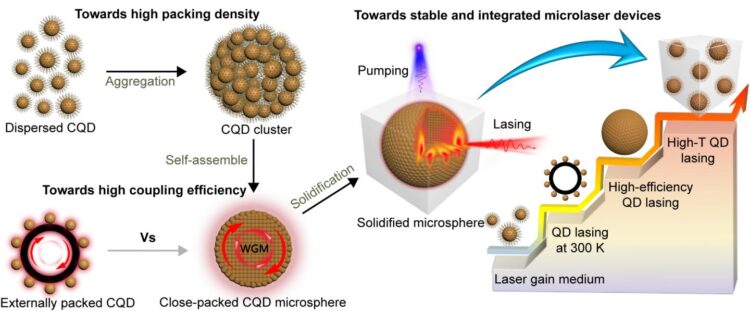

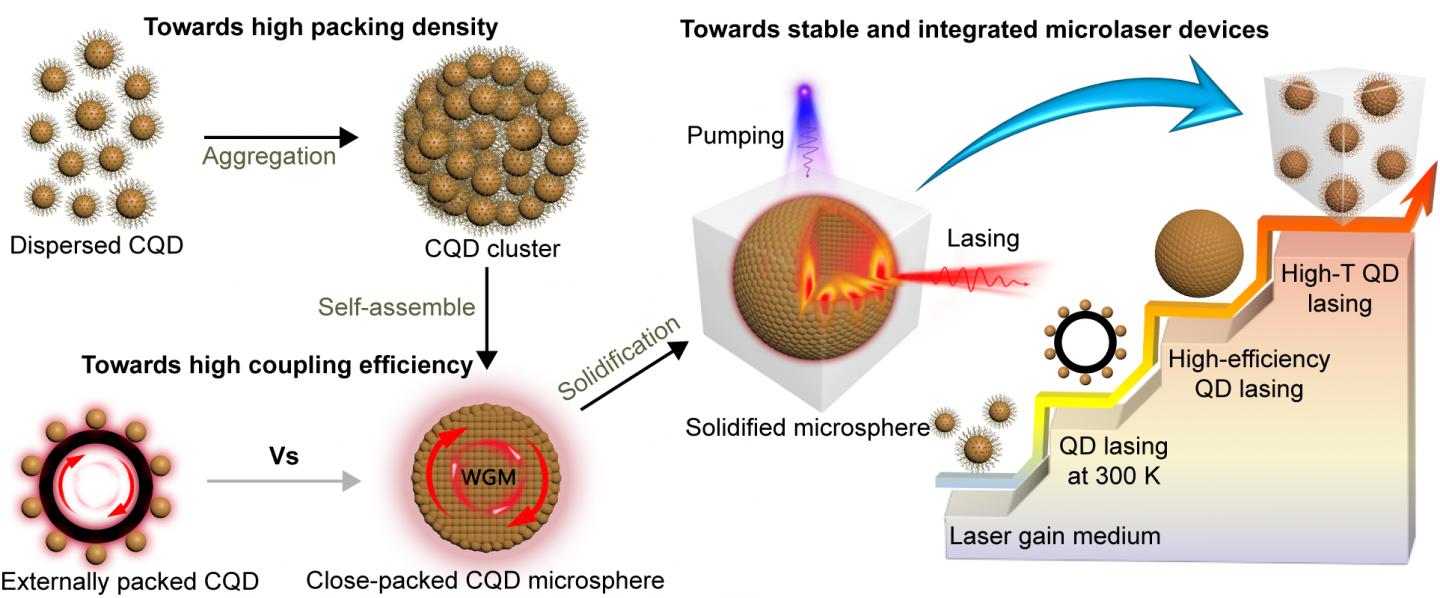

Low-dimensional colloidal quantum dots (CQD) have attracted significant attention because of their unique structures, extraordinary optical properties, and low-cost preparation processes. Since its first synthesis in the 1990s, motivation to realize high-performance low-cost CQD micro-/nanolasers have been a driving force for more than three decades. However, the low packing density, inefficient coupling of CQD with optical cavities, and the poor thermal stability of miniaturized complex systems make it challenging to achieve practical CQD micro-/nanolasers, especially to combine the continuous working ability at high temperatures and the low-cost potential with mass-produced synthesis technologies. Hence, how to solve above key problems efficiently needs to new ideas different from the traditional CQD laser research.

In a new paper published in Light Science & Application, a team of scientists, led by Professor Hongxing Dong and Professor Long Zhang from Key Laboratory of Materials for High-Power Laser, Shanghai Institute of Optics and Fine Mechanics, Chinese Academy of Sciences, China, and co-workers have developed a novel assembly technique combined with the sol-gel method to fabricate CQD-assembled microspheres (CQDAMs) solidified in a silica matrix, which not only guarantees that the CQDAMs work stably at high temperatures but also solves the problems of gain packing density and coupling efficiency. Researchers first achieved single-mode lasing based on solidified CQDAMs with operative temperatures up to 450 K. So far, this is the highest operational temperature for CQD microlasers. Even if they continuously work in such a high-temperature environment, the stable output of lasing pulses can be maintained for 40 min. By changing the composition and/or size of CQD, single-mode lasing can be extended to the entire visible spectral range. Moreover, the solution-processable method has the advantages of low cost and potential for mass-production. It does not require complex optical cavity processing, which means no expensive equipment or extremely complex processing is required. Meanwhile, these CQDAMs lasers can be highly integrated in a micro-substrate, and also applicable to other kinds of semiconductor nanoparticles, which promote predictable commercial application value in high-temperature low-cost micro-integrated optoelectronic devices.

In the research field of micro-/nanolasers devices, high-performance low-cost CQD laser is an important hot topic. Unfortunately, the development is obviously hysteretic considering the coexistence of the multi-level challenges, that is, (1) the basal requirement of excellent lasing performance; (2) the promotional ability to meet the application conditions such as continuous working with high stability, applicability in high-temperature environments; (3) the combination of low-cost production advantage and the merits in previous points (1), (2). These scientists summarize the original design ideas of their microlasers:

“From the point view of gain medium, the self-assembled CQD almost reach the high limit of packing density, ensuring sufficient optical gain. From the point view of light-matter coupling, such CQDAM samples are used both as gain materials and as optical microcavities, fully improving the light-matter coupling efficiency. From the point view of optical cavity performance, the spherical WGM microcavity can effectively improve the confinement ability of cavity photons. For a CQDAM sample of volume of about 1 μm-3, there could be only a single resonant mode effected in the emission wavelength range. However, the Q factor of operative mode could be 104. Most importantly, we combine these three advantages of different aspects together into the CQDAM sample.”

“Besides the above laser parameters, the lasing stability at high temperature is also an important aspect related with commercialization potential. The heat dissipation problem is an intrinsic and inevitable difficulty for the next generation of microchip-integrated lasing devices. In this work, the operative temperature of CQDs microlaser is demonstrated to promote to 450 K. Moreover, the CQDs microlaser can be high-density integrated with excellent working ability even at such a high temperature. In addition, our unique but generic CQD microlasers fabrication method is very attractive and promising from a commercial standpoint where they can greatly reduce manufacturing cost and simplify the manufacturing process, thereby benefiting their large-scale industrial production. In other words, this highly efficient solution-preparation processes do not need complex processing techniques and expensive processing equipment, the costs are mainly the low-priced materials. This cost-effective manufacturability and the flexible integration capability pave a new route and promise a great potential in the advancement of CQD microlasers from laboratory to industrialization.” they added.

“In addition, ever since the first demonstration of stimulated emission from CQD, the pursuit of electrically pumped CQD lasing has become the subject of intense research. Interestingly, our CQDAMs can serve as both gain medium and optical cavity, which can be readily incorporated into the electroluminescent architecture as emitting layer to enable electrically pumped nanolasers. In fact, the realization of electro induced micro laser is a great challenge, and more complex problems need to be solved, which is also an important content of our future research.” the scientists forecast.

###

Media Contact

Hongxing Dong

[email protected]

Related Journal Article

http://dx.