Credit: RUDN University

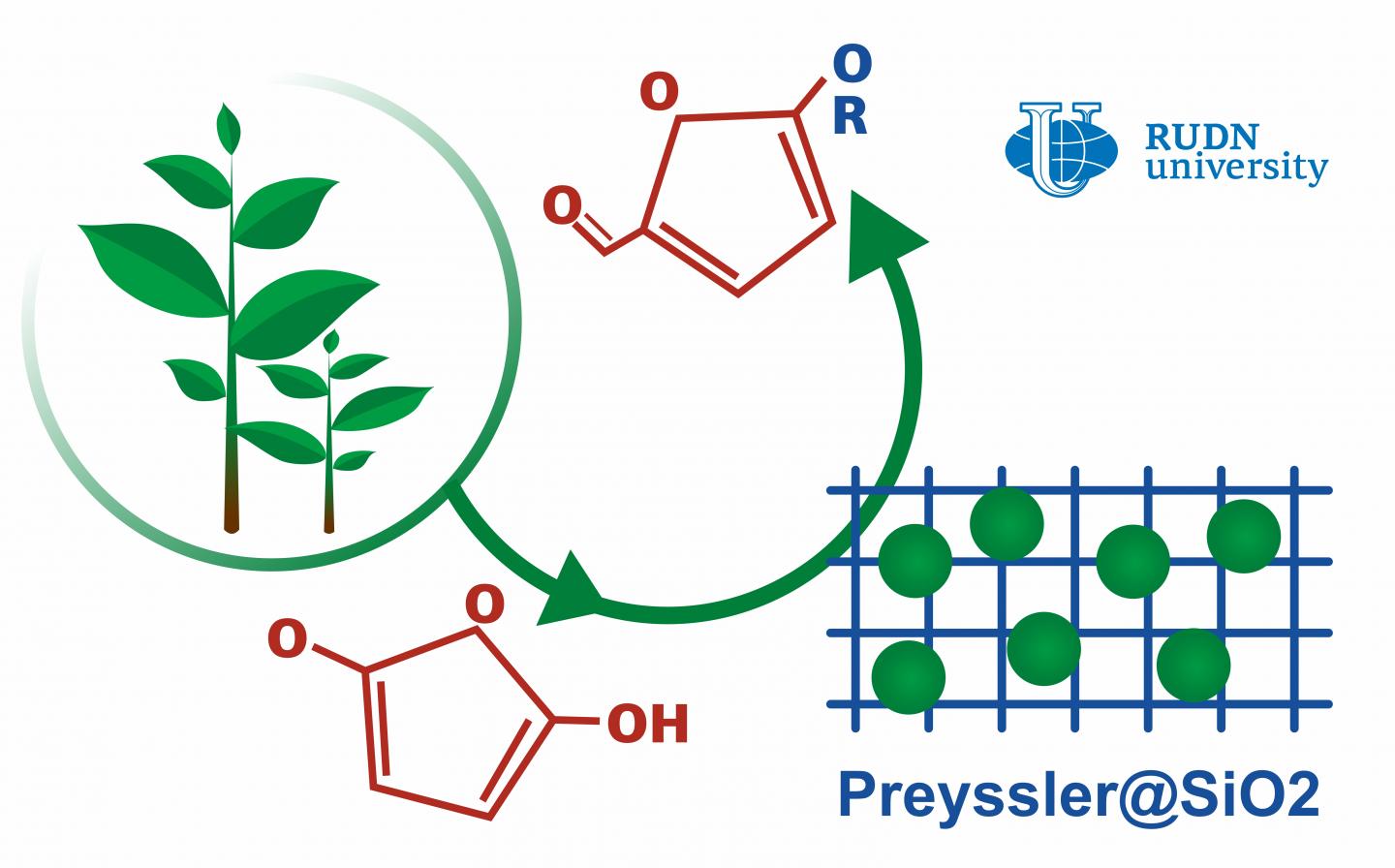

A chemist from RUDN University developed a silica-supported heteropolyacid system to produce ethers from waste products of the wood and paper industry and agriculture. Ethers can be used as biofuels, and the new method increases the efficiency of their production 4 to 10 times, thus reducing energy consumption and making the manufacturing of biofuels cheaper. The results of the study were published in the Molecular Catalysis journal.

The production of biofuel from non edible feedstocks is one of the main goals for a more sustainable future. As a rule, one of the most relevant feedstocks for it is lignocellulose–dry waste products of the wood and paper industry or agriculture. Among other components, lignocellulose contains hydroxymethyl furfural or HMF. From it one can obtain ethers that are used as eco-friendly fuel. A chemist from RUDN University developed a molecular matrix (xerogel) containing Preyssler heteropolyacids that increases the efficiency of ether production from HMF 4 to 10 times.

“HMF is a small molecule that has a lot of attention in industry. Its etherification is an important field of research because the products of this reaction are used as fuel and precursors of complex molecules. We tried to optimize HMF etherification with a silica xerogel containing heteropolyacids,” said Rafael Luque, PhD, the head of the Molecular Design and Synthesis of Innovative Compounds for Medicine Science Center at RUDN University.

To produce ethers, HMF has to react with alcohols, so the researchers used butanol in their studies. The so-called Preyssler acids acted as a catalyst. They could have worked on their own, but the team found a way to modulate their activity. The chemists developed a xerogel from silica dioxide and immobilized the Preyssler acids on it. Acid molecules were distributed across the molecular matrix of the xerogel, thus increasing the contact area with HMF. As a result, the xerogel increased both the conversion of the reaction (i.e. the amount of reacting HMF) and its selectivity (the quantity of produced ether as compared to other products).

Having conducted a series of experiments, the team identified optimum reaction parameters: the temperature at 100 ?, and the HMF to butanol ratio at 1 to 3. In these conditions, the level of conversion reached 89%, and selectivity was 73%. Therefore, using the catalytic system, one can obtain a given amount of ether from considerably less primary product. This would reduce energy consumption and make the production process cheaper. Moreover, the xerogel can be treated with ethanol and reused up to 5 times, with conversion and selectivity dropping only to 50% and 60% respectively after all 5 cycles.

“The parameters that we identified can be applied to similar reactions of HMF with other alcohols to obtain ethers with different structures. Such ethers can further be used as fuel or precursors for complex molecules,” added Rafael Luque, PhD, the head of the Molecular Design and Synthesis of Innovative Compounds for Medicine Science Center at RUDN University.

###

Media Contact

Valeriya Antonova

[email protected]

Related Journal Article

http://dx.