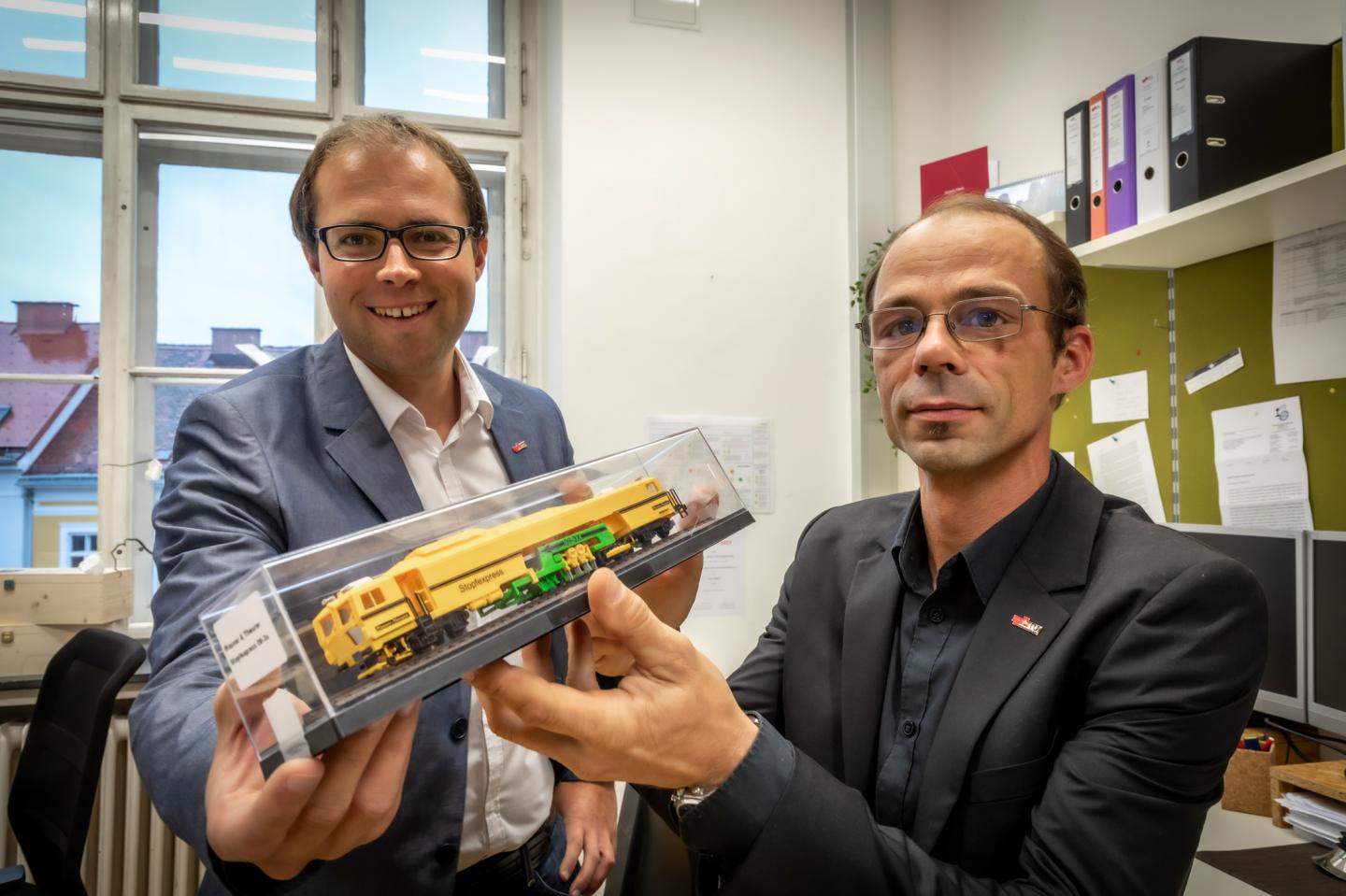

Credit: © Lunghammer – TU Graz

Train journeys should be safe and comfortable, and track systems are crucial to this. So-called “tamping” (positioning, compacting and stabilizing) of the ballast in the track bed is one of the most important maintenance tasks in the railway industry. Special tamping machines lift the tracks, align them precisely and tamp the ballast below the sleepers so that the tracks are back in the desired position.

Tamping work has to be carried out at the latest when the condition of the tracks reaches safety-critical limits – something which rarely happens in Austria, however, because OEBB (Austrian Federal Railways) maintains its network at a very good quality level. But Johannes Neuhold from the Institute of Railway Engineering and Transport Economy at Graz University of Technology has made the following observation: “Even though data-based decisions are increasingly replacing gut instinct, in Austria, tamping planning is still frequently based on the availability of tamping machines.”

The right time for tamping work

With the support of supervisor Stefan Marschnig in his dissertation, Neuhold has now turned his attention to finding the ideal time for tamping operations and putting planning on a more objective basis, “so that they are only carried out on tracks where they are necessary but also make economic sense.” The focus was on a long service life with as few (and therefore cheaper) maintenance measures as possible. “While in the case of good tracks, for example, early intervention will maintain the quality for a long time, it may make more sense in the case of bad tracks to dispense with tamping measures and accept the lower quality level. An improvement in the situation of poor tracks requires a lot of maintenance money. However, the quality cannot be improved in the long term because a track always only comes close to its initial level. The use of funds would therefore be disproportionate.”

Algorithm provides planning reliability

The core of the work is an algorithm that calculates when and how often tamping measures are appropriate on the basis of various parameters such as the age and condition of the tracks, the components used and the cumulative load. As Marschnig explains, the load in particular is a key criterion: “On lines where the tracks are used heavily by heavy freight traffic, wear occurs more quickly than on lines where mainly suburban trains are in operation.” The measurement data for the calculations was provided by the OEBB, which are long-standing partners of the Institute.

Longer service life reduces life cycle costs

To calculate the life-cycle costs, the researchers generated comparative values and made the assumption that a track can be tamped ten times during its life cycle. The results showed that by extending the tamping cycles – i.e. if the measures are not carried out continuously as in the past, but planned in a targeted manner – a longer service life of the tracks is achieved. “Due to the longer useful life and the associated depreciation of the asset values, the life-cycle costs are reduced by up to twenty per cent,” argue Marschnig and Neuhold. The two experts now hope that railway infrastructure companies will apply the method and bring more structure to the maintenance work on track systems.

###

This research work at the Institute of Railway Engineering and Transport Economy is anchored in the Fields of Expertise “Sustainable Systems” and “Mobility & Production”, two of the five research foci of Graz University of Technology.

Contacts TU Graz | Institute of Railway Engineering and Transport Economy:

Stefan MARSCHNIG

Assoc.Prof. Dipl.-Ing. Dr.techn.

Phone +43 (316) 873 6717

[email protected]

Johannes NEUHOLD

Dipl.-Ing. Dipl.-Ing. Dr.techn. BSc

Phone +43 (316) 873 6717

[email protected]

Media Contact

Stefan MARSCHNIG

[email protected]

Original Source

https:/