Credit: SHI Dingqin

The development of renewable energies such as wind energy and solar energy is limited by their inherently random and intermittent nature.

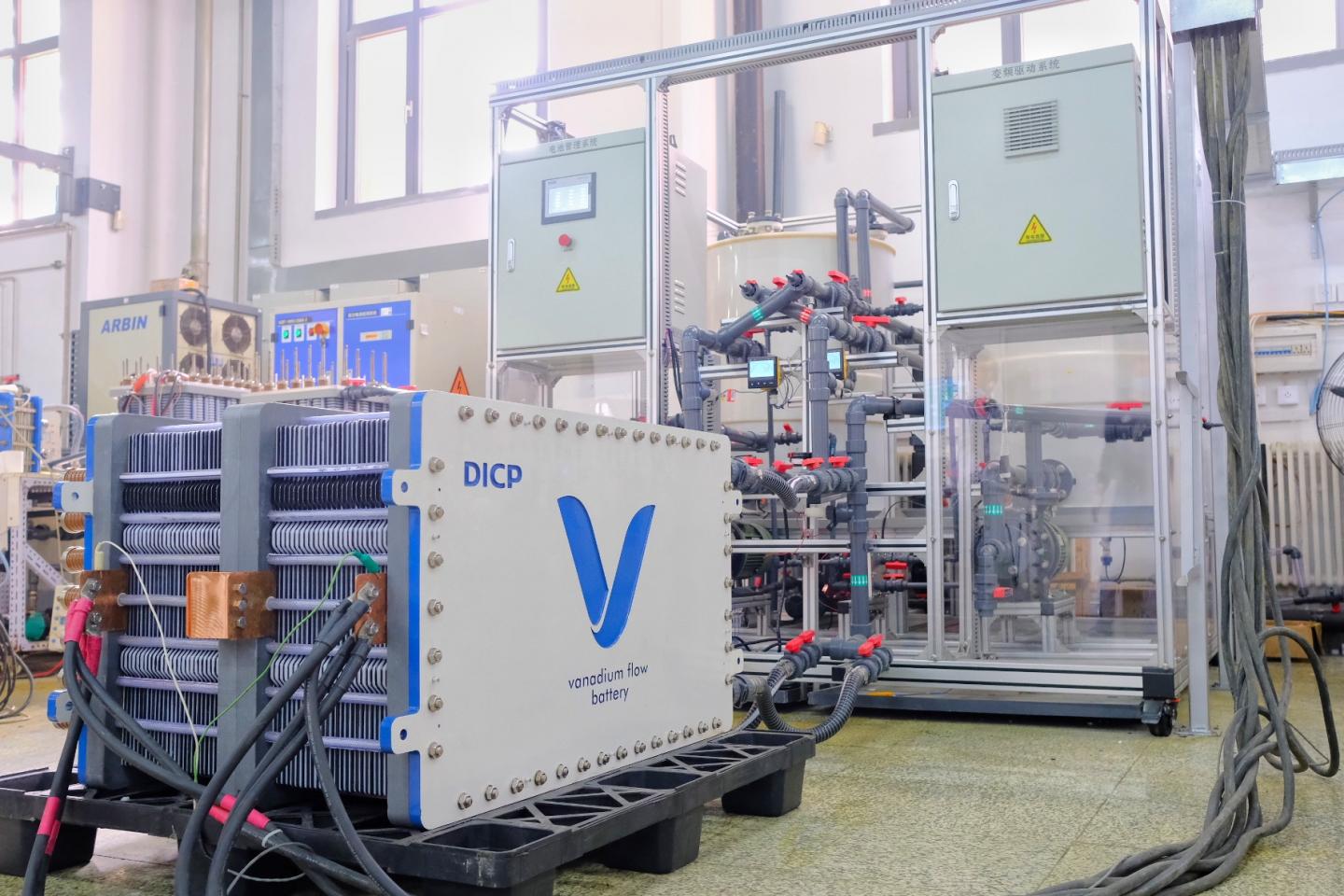

However, the vanadium flow battery (VFB) offers a cost- and energy-efficient, long-life energy storage technology that can store and smoothly output power from renewable energies.

The VFB energy storage system mainly comprises the stack, the electrolyte, and systems for pipeline, battery management and energy conversion. Among these components, the stack plays a crucial role. Therefore, increasing the stack’s power density and reducing its cost will further accelerate the industrialization of VFB technology.

A research group led by Prof. LI Xianfeng from the Dalian Institute of Chemical Physics (DICP) of the Chinese Academy of Sciences has developed a new generation of VFB stack technology that offers low cost and high power density.

The group’s test results showed stack energy efficiency exceeding 81%. The stack ran at a constant power of 30 kW and showed no capacity decay after 100 cycles.

“The stack assembly process was improved by applying weldable, porous ionic conductive membranes that we developed,” said Prof. LI.

Laser welding technology was used in the stack assembly for the first time. It not only improved the reliability of the stack, but also achieved automation of the stack assembly, decreased the use of sealing materials, and reduced the cost of the stack.

“This new VFB stack technology not only maintains the high power density of conventional stacks, but also reduces total cost by 40% compared to conventional stacks,” said Prof. LI.

The membranes used in conventional VFB stacks are mainly commercial perfluorosulfonic acid membranes characterized by high cost and relatively poor ion selectivity.

In contrast, the weldable, porous ionic conductive membranes adopted in this new generation of VFB stack technology can improve ionic selectivity and increase the capacity retention of the electrolyte. This type of membrane costs much less than perfluorosulfonic acid membranes.

###

Media Contact

WANG Yongjin

[email protected]

Original Source

http://english.