Credit: by Changji Pan, Lan Jiang, Jingya Sun, Qingsong Wang, Feifei Wang, Kai Wang, Yongfeng Lu, Yeliang Wang, Liangti Qu and Tianhong Cui

Molybdenum disulfide (MoS2) has attracted considerable attention because of its potential applications in field-effect transistors, optoelectronic devices, and electrocatalysts, among others. For successful application of MoS2 in optoelectronics, it is necessary to understand the electron dynamics, which is known to determine the electronic transport and optical properties of semiconductors. In addition to its importance in optoelectronics applications, the ultrafast electron dynamics also plays a vital role in the laser fabrication of MoS2. Numerous valuable studies on the electron dynamics have already focused on the attractive properties of MoS2; however, they all investigated the free electron density below the damage level. At a laser fluence above the damage threshold, the electron dynamics may differ from that under lower-energy excitation. Therefore, it is necessary to provide deeper insights into the electron dynamics when an ultrafast intense laser pulse is applied.

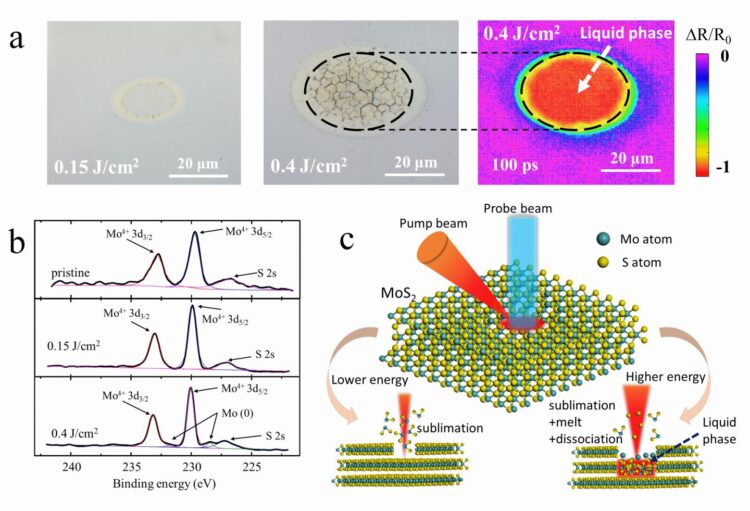

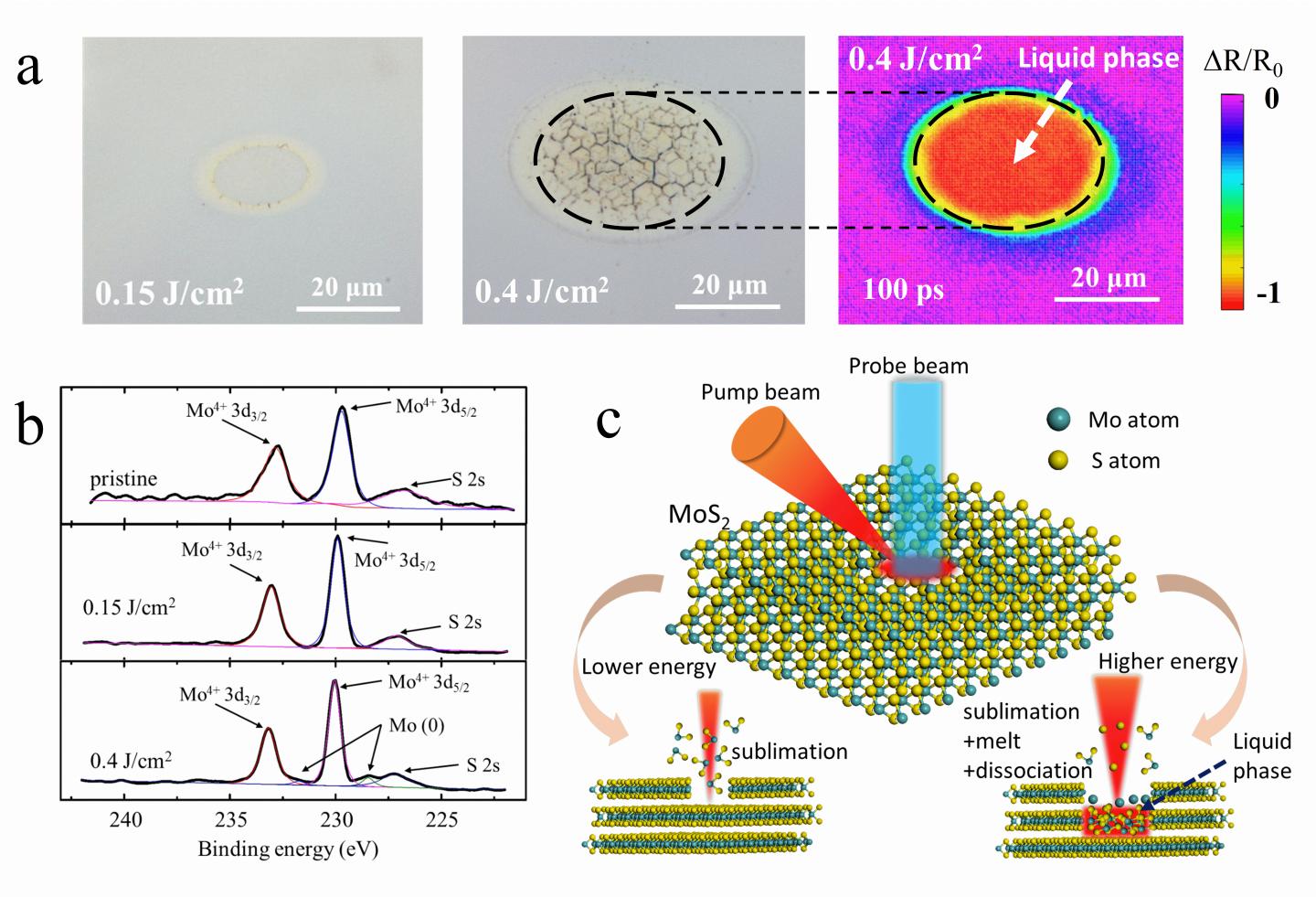

In a new paper published in Light Science & Application, scientists from the Laser Micro/Nano-Fabrication Laboratory, School of Mechanical Engineering, Beijing Institute of Technology, Beijing 100081, PR China, in cooperation with a scientist at the University of Minnesota, predicted and examined what happens to molybdenum disulfide on the electron and lattice level under irradiation by intense femtosecond laser pulses. A theoretical model was first developed for MoS2 to simulate electron dynamics during femtosecond laser ablation processes. Simultaneously, a pump-probe setup was constructed to detect the ultrafast optical response of MoS2 under irradiation by intense femtosecond laser pulses. The results revealed two types of ablation mechanisms, which led to two distinct types of electron dynamics and final ablation morphology. At a higher fluence, the emergence of a superheated liquid induced a dramatic change in the transient reflectivity and micro-honeycomb structures. At a lower fluence, the material was just removed by sublimation, and the ablation structure was relatively flat. To further examine the ablated surface, X-ray photoelectron spectroscopy (XPS) measurement was performed. The results demonstrated that thermal decomposition occurred only at the higher fluence. According to the simulation results, under a higher fluence, the lattice temperature was much higher than the melting point of MoS2, whereas under a lower fluence, the lattice temperature was just below the melting point. The simulation results were in good agreement with the XPS results, as well as pump-probe detection.

The simulated and experimental results revealed the behaviour of electrons and the lattice during femtosecond laser ablation of MoS2, which enabled the manufacturing processes to be presented from electron level. This method and theoretical model provide a new perspective for understanding the mechanism of femtosecond laser processing, and even the control of the patterns and properties of materials. These scientists summarise their simulated and experimental work:

“We built up a theoretical model for MoS2 to account for several complex physical processes during femtosecond laser ablation, including (1) photoionisation, (2) free electron heating, (3) impact ionisation, (4) electron-lattice coupling, and (5) free electron recombination.”

“We constructed a pump-probe setup to directly detect the ultrafast optical response of MoS2 under irradiation by intense femtosecond pulses. This detection system can detect the evolution of the electron dynamics with high spatial and temporal resolution.”

“Our simulation results are in good agreement with the detection results, which indicates that the model is valid for predicting the interaction between a femtosecond laser and MoS2, and further provides more detailed information on the ultrafast electron dynamics during ablation processes.”

###

Media Contact

Lan Jiang

[email protected]

Related Journal Article

http://dx.