Credit: by Zhen-Ze Li, Lei Wang, Hua Fan, Yan-Hao Yu, Qi-Dai Chen, Saulius Juodkazis and Hong-Bo Sun

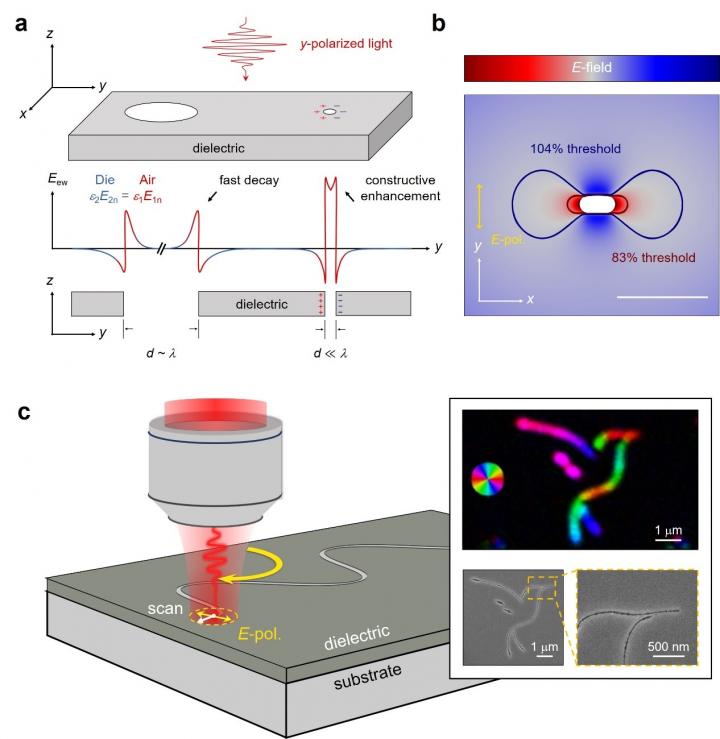

Lasers are becoming one of the dominant tools in the current manufacturing industry. Much effort has been devoted to improving the processing accuracy, and spatial resolutions as low as micrometers have been achieved in laser cutting, wedding, marking and stereolithography in an atmospheric environment. The femtosecond laser (fs-laser) is a particularly promising approach from this point of view, in addition to its three-dimensional (3D) processing capability and broad-spectrum material usability. Super-diffraction-limited feature sizes at a level of tens of nanometers based on multiphoton absorption thresholding, shrinkage and stimulation emission depletion effects have also been realized in fs-laser induced photocuring of polymers, which unfortunately are not applicable to solid materials. Optical near-field techniques provide an alternative super-resolution scheme by localizing light fields to nanometer scales with the physical shapes of sharp tips, tiny apertures, nanoparticles and small protrusions. Nevertheless, these approaches often rely on heavy movement and alignment systems to maintain precise probe-substrate spacing for practical fabrication/patterning throughput due to the evanescent nature of the near field. An innovative optical patterning technology that permits vacuum-free high-resolution processing comparable to conventional FIB processing is highly desired.In a new paper published in Light Science & Application, scientists from the State Key Laboratory of Precision Measurement Technology and Instruments, Department of Precision Instrument, Tsinghua University, Beijing, China, the State Key Laboratory of Integrated Optoelectronics, College of Electronic Science and Engineering, Jilin University, Changchun, China, and the Nanotechnology facility, Swinburne University of Technology, John st., Hawthorn, Australia reported an optical far-field-induced near-field breakdown (O-FIB) approach, allowing the nanofabrication applicable to almost any solid materials in atmosphere. The writing is initiated from nano-holes created by femtosecond laser induced multiphoton absorption and its cutting “knife edge” is sharpened by far-field regulated enhancement of the optical near field. A spatial resolution of sub-20 nm (λ/40 for light wavelength λ) is readily achieved. O-FIB is empowered by a simple polarization control of the incident light for steering nano-groove writing along the designed pattern.

“According to the continuous boundary condition of the normal component of electric displacement, we experimentally observed the light field nano-localization and polarization-vertical enhancement around the nanohole, which permits direct control of the near-field enhancement for nanoablation by far field. Based on this idea, we have realized free nano-writing with resolution as high as 18 nm by manipulating laser polarization and beam’s trajectory in real time.”

“Since for the self-regulation effect induced by the feedback between light and the initial seeds, our approach has the inherent robustness against the stochastic nature of initial ablation and the ability to manipulate line width. Besides, our approach demonstrates free-form stitchless writing of nano-grooves with controllable length, separation and trajectory. Meanwhile, the universality of seeding effect enables a large-area printing mode which is superior to the conventional FIB.”

“Our presented technique has opened a new era of high-efficient nanomachining. It is applicable for various materials and surface in the fields of nanoelectronics, nanofluids, and nanomedicines. The possibility we show here to direct manipulating the near field through the far field, may inspire the researchers to push the femtosecond laser nanofabrication or even other domains of the optical processing to a higher level.” The scientists forecast.

###

Media Contact

Hong-Bo Sun

[email protected]

Related Journal Article

http://dx.