The results were published in Fuel

Credit: Kazan Federal University

Thermal oil extraction gets more and more recognition in scientific circles. However, combustion is a rather complex research problem, and it’s one of the focuses of Kazan University’s work.

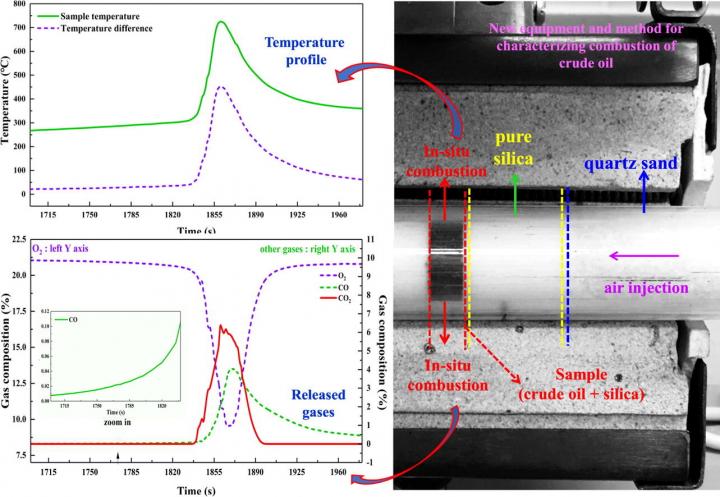

In this project, a porous medium thermo-effect cell (PMTEC) was used. ‘Thanks to this technology, we can test and visualize the in-situ combustion process. The cell is made of quartz glass, and it contains a petroleum-bearing layer model. We can conduct screening test for various types of oil with regards to their susceptibility to high-temperature combustion,’ explains Mikhail Varfolomeev, Head of EcoOil Research Unit. ‘A glass tube is placed in a furnace to maintain heat treatment. Inside the tube is an oil-bearing rock. Air flow then goes through the tube, imitating steam injection into the reservoir, and then oxidation is measured.’

It turned out that the low-temperature combustion (LTC) occurring in the porous medium thermo-effect cell was different from the low-temperature or high-temperature oxidation observed from high-pressure differential scanning calorimetry experiments. In addition, this LTC can propagate in porous media with air flow, which was detected by a newly developed optical fibre technology instead of traditional thermal couples. Furthermore, the effect of copper stearate, iron stearate, nickel stearate, and cobalt stearate as oil-soluble catalysts on the LTC was investigated. Copper stearate showed the best catalytic effect. It significantly shifted onset and peak temperatures into lower temperature from 278 and 287°C to 227 and 237°C, respectively, exhibiting a great potential in catalyzing crude oils combustion in ISC process. The catalytic effect of these four catalysts is in order of efficiency: copper > iron > cobalt > nickel.

###

Note: This publication was made available online in October 2019 and is scheduled to be released in print in January 2020.

Media Contact

Yury Nurmeev

[email protected]

Original Source

https:/

Related Journal Article

http://dx.