Credit: SUTD & SUSTech

With increasing demand for miniaturization of optoelectronics, microlens array has attracted significant attention and become an important micro-optics device widely used in compact imaging, sensing, optical communication and others. Typically, microlens array consists of multiple micron-sized lenses with optical surface smoothness and superior uniformity, which increases the requirement for machining precision.

Despite the tremendous progress made in manufacturing techniques during the past decades, some limitations, such as high time consumption, high process complexity, lack of fabrication flexibility, and difficulty in consistency control for the existing techniques, still exist.

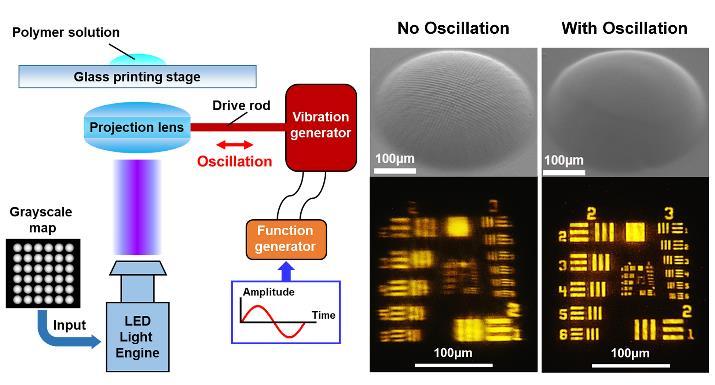

Recently, researchers from the Singapore University of Technology and Design (SUTD) and Southern University of Science and Technology (SUSTech) in Shenzhen, China proposed an approach which integrated oscillation-assisted digital light processing (DLP) 3D printing with grayscale UV exposure to render an ultrafast and flexible fabrication of microlens arrays with optical surface smoothness.

“3D printing of small geometries with optical surface smoothness is a big challenge.” said the project leader, Associate Prof Qi Ge from SUSTech, “In our approach, the computationally designed grayscale patterns are employed to realize microlens profiles upon one single UV exposure which removes the staircase effect existing in the traditional layer-by-layer 3D printing method, and the projection lens oscillation is applied to further eliminate the jagged surface formed due to the gaps between discrete pixels.”

Detailed morphology characterizations including scanning electron microscopy (SEM) and atomic force microscopy (AFM) prove that the integration of projection lens oscillation considerably smoothens the lens surface and reduces the surface roughness from 200 nm to about 1 nm.

“In addition to surface roughness, lens profile also plays a key role in optical performance.” said Chao Yuan, the co-first author of the paper and a postdoctoral research fellow from SUTD, “In order to better assist the grayscale design for microlens array fabrication, we developed a theoretical model to describe the photopolymerization process and predict the lens profile.”

“The DLP based 3D printing affords remarkable flexibility to the fabrication of microlens arrays. Microlenses with different sizes, geometries and profiles are printable upon one single UV exposure with different grayscale patterns.” said Kavin Kowsari, the other co-first author of the paper and a postdoctoral research fellow from SUTD.

“Relative to the other fabrication method, our oscillation assisted DLP based printing method is energy- and time-efficient without degradation of optical performance, which is convenient for commercialization and deployment into mass production.” said Prof Ge, “Also, this approach provides instructive inspirations for other manufacturing fields with high demands for ultra-smooth surfaces.”

###

This work was funded by SUTD’s Digital Manufacturing and Design (DManD) Centre which is supported by the Singapore National Research Foundation (NRF). The research was published in ACS Applied Materials & Interfaces.

Media Contact

Melissa Koh

[email protected]

65-649-98742

Related Journal Article

http://dx.