In a groundbreaking advancement at the intersection of additive manufacturing and green chemistry, researchers have unveiled a novel method for tackling one of the most persistent environmental pollutants: volatile organic compounds (VOCs). The study, recently published in npj Advanced Manufacturing, demonstrates the revolutionary potential of VAT 3D printing to produce polymerizable ionic liquids (PILs) tailored specifically for VOC capture. This fusion of cutting-edge materials science with precision manufacturing not only promises enhanced efficiency in air purification technologies but also signals a transformative step toward sustainable industrial processes.

Volatile organic compounds, a broad class of carbon-based chemicals that readily vaporize at room temperature, are notorious contributors to air pollution. Emitted from a variety of sources including industrial solvents, vehicle exhaust, and household products, VOCs are linked to adverse health effects and environmental degradation. Traditional methods for VOC removal, such as activated carbon filters and scrubbers, are often limited by regeneration difficulties, inefficiency in selective capture, and high operational costs. This has spurred intense research into alternative materials capable of selective VOC adsorption, recycling, and easy integration into filtration devices.

Enter polymerizable ionic liquids—designer molecules that combine the unique properties of ionic liquids with the structural versatility of polymers. Ionic liquids are salts in a liquid state at relatively low temperatures, prized for their negligible vapor pressure, tunable polarity, and solvent capabilities. By rendering them polymerizable, scientists can transform these liquids into solid matrices that retain ionic characteristics, while offering mechanical stability and customizable architectures. These hybrid materials have shown immense promise in separations, catalysis, and gas capture due to their selective interactions with target molecules and robustness under various conditions.

.adsslot_o0Of26PYqJ{width:728px !important;height:90px !important;}

@media(max-width:1199px){ .adsslot_o0Of26PYqJ{width:468px !important;height:60px !important;}

}

@media(max-width:767px){ .adsslot_o0Of26PYqJ{width:320px !important;height:50px !important;}

}

ADVERTISEMENT

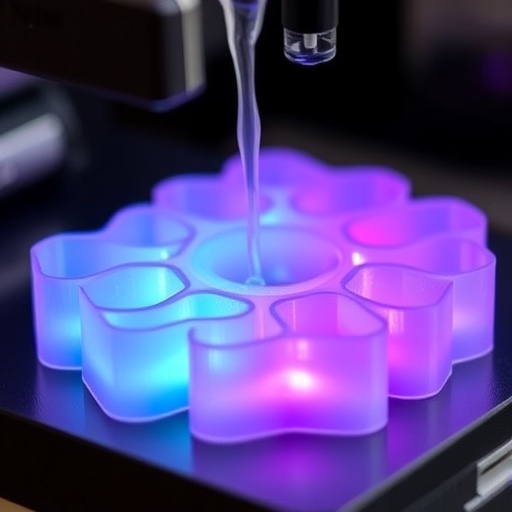

The pioneering work from Armandi, Tosetto, Roppolo, and colleagues harnesses VAT (Vat Photopolymerization) 3D printing technology to fabricate three-dimensional structures comprised entirely of polymerizable ionic liquids. VAT 3D printing operates by selectively curing layers of liquid photopolymer resin using specific wavelengths of light, allowing for precise control over geometry and internal porosity. While 3D printing of polymers is well-established, embedding ionic liquid monomers as the printable resin represents a significant materials science challenge, demanding fine-tuned photochemistry and rheological properties.

This research surmounted these hurdles by meticulously designing ionic liquid monomers with polymerizable acrylate functional groups, optimizing their photoreactivity, and balancing viscosity to enable smooth VAT printing. The resulting printed materials form porous lattices with accessible internal surfaces optimized for capturing VOC molecules. The team demonstrated that these 3D printed PILs exhibit exceptional adsorption capacities, outperforming conventional sorbents in both uptake and selectivity towards diverse volatile organic compounds ranging from benzene derivatives to aliphatic hydrocarbons.

Beyond material fabrication, the study delves into the physicochemical interactions driving VOC adsorption within these polymerized ionic liquids. The researchers report that the ionic moieties within the polymer matrix establish strong Coulombic and hydrogen bonding interactions with polar VOCs, while hydrophobic domains enhance affinity toward nonpolar species. This dual-interaction mode imparts broad-spectrum capture capability, addressing the complexity of real-world VOC mixtures. Moreover, the inherent low vapor pressure and thermal stability of the PILs ensure durability in fluctuating operational environments, a key requirement for long-term use.

Another futuristic facet highlighted in the research is the recyclability and regeneration potential of these printed VOC adsorbents. Regenerability is a longstanding bottleneck in VOC management systems; however, these PIL lattices can be thermally or solvent-treated to liberate sequestered compounds without significant loss of structural or chemical integrity. This regeneration cycle not only reduces waste and operational costs but also opens avenues for reclaiming valuable organic compounds, turning pollutant capture into resource recovery—a paradigm shift for environmental technologies.

The team also explored the integration of the 3D printed PILs within prototype air filtration units, assessing real-time VOC capture efficiency. The results affirmed that printed grids and meshes based on these materials facilitate high airflow rates while maintaining VOC removal efficiency, a balance rarely achieved by conventional adsorbents. This compatibility with airflow dynamics suggests seamless adoption into existing HVAC systems, industrial ducts, or portable air purifier designs, greatly enhancing the applicability to diverse environments including offices, factories, and residential spaces.

From a manufacturing perspective, the study underscores the scalability potential of VAT 3D printing to produce these advanced materials. The speed and resolution of the printing process allow for rapid prototyping, customization, and eventual mass production. By combining CAD design with material chemistry, each printed component can be uniquely tailored to site-specific pollution profiles, operational constraints, or spatial considerations—hallmarks of Industry 4.0 and smart manufacturing.

Importantly, this research heralds a broader implication beyond VOC capture. It exemplifies the power of combining ionic liquids with additive manufacturing to create functional materials that were previously impractical or impossible to fabricate. Such materials could be extended to other environmental applications like CO2 capture, water purification, or catalytic reactors, showcasing an expansive horizon for polymerizable ionic liquids and 3D printing.

Moreover, the environmental impact of VOCs extends across multiple sectors including transportation, manufacturing, and even consumer products. Innovations like the ones presented here offer hope for mitigating air pollution with minimal ecological footprint, addressing climate change challenges, and improving public health outcomes. As regulations on air quality tighten globally, scalable, efficient, and adaptable technologies such as these become indispensable tools in the sustainable development toolkit.

While the study represents a major breakthrough, the authors also acknowledge challenges that remain. Long-term stability under cycling, mechanical fatigue resistance, cost competitiveness, and compatibility with diverse VOC mixtures under real atmospheric conditions require further investigation. Nonetheless, the synergistic combination of chemistry, materials science, and manufacturing innovation provides a robust platform to accelerate these developments.

In conclusion, the successful fabrication of polymerizable ionic liquid-based VOC capture materials through VAT 3D printing not only revolutionizes material design but also sets a precedent for integrating smart chemistry with digital manufacturing. This work exemplifies a visionary approach to environmental remediation, highlighting the capacity of next-generation materials to address urgent global challenges through precision, adaptability, and sustainability.

As the research community continues to explore the untapped potential of ionic liquids in polymeric form, and additive manufacturing technologies evolve, we can anticipate an exciting era where the boundaries between material properties, design freedom, and application feasibility blur, leading to innovative solutions with profound societal impact. The future of clean air technologies, thanks to these flexible and efficient VOC capture materials, looks brighter and cleaner than ever before.

Subject of Research:

Polymerizable ionic liquids fabricated via VAT 3D printing for selective capture and removal of volatile organic compounds (VOCs).

Article Title:

VAT 3D printing of polymerizable ionic liquids for VOC capture.

Article References:

Armandi, M., Tosetto, B., Roppolo, I. et al. VAT 3D printing of polymerizable ionic liquids for VOC capture. npj Adv. Manuf. 2, 32 (2025). https://doi.org/10.1038/s44334-025-00041-0

Image Credits:

AI Generated

Tags: 3D printing technology for environmental applicationsadditive manufacturing in green chemistryadvanced materials for pollution controlchallenges in VOC removal methodsdesigner molecules for selective adsorption.efficiency in air filtration technologiesenvironmental impact of volatile organic compoundsinnovative methods for air purificationintegration of ionic liquids in filtration devicespolymerizable ionic liquids for VOC captureresearch advancements in air quality improvementsustainable solutions for volatile organic compounds