In the rapidly evolving landscape of tissue engineering and regenerative medicine, the orientation of collagen fibers within biological tissues remains a critical yet elusive factor for replicating the complex microstructures found in nature. Collagen, the most abundant structural protein in animal connective tissues, plays a fundamental role in maintaining tissue integrity, mechanical strength, and cellular function. Yet, the fine details of how its fibers assemble and orient to confer these functional properties have long evaded full scientific understanding. Now, a pioneering study from researchers at YOKOHAMA National University unveils a novel approach to fabricating multidirectionally oriented collagen hydrogels, leveraging fluid dynamics and cutting-edge three-dimensional (3D) printing technology to mimic the natural anisotropy seen in tissues like skin dermis and skull bone.

Collagen’s unique hierarchical assembly, from molecules to fibrils to fibers, imparts anisotropic mechanical properties that are vital for tissue-specific function. Traditional methods of collagen orientation, including magnetic alignment and electrospinning, encounter significant limitations. Magnetic techniques risk embedding residual magnetic beads that compromise biocompatibility, while electrospinning requires volatile organic solvents that raise safety concerns and complicate clinical translation. The innovative method designed by the YOKOHAMA team circumvents these pitfalls by using pure type I collagen solutions combined with cells, shaped in microfluidic channels fabricated by 3D printing, thereby eliminating the need for extraneous chemicals or particles.

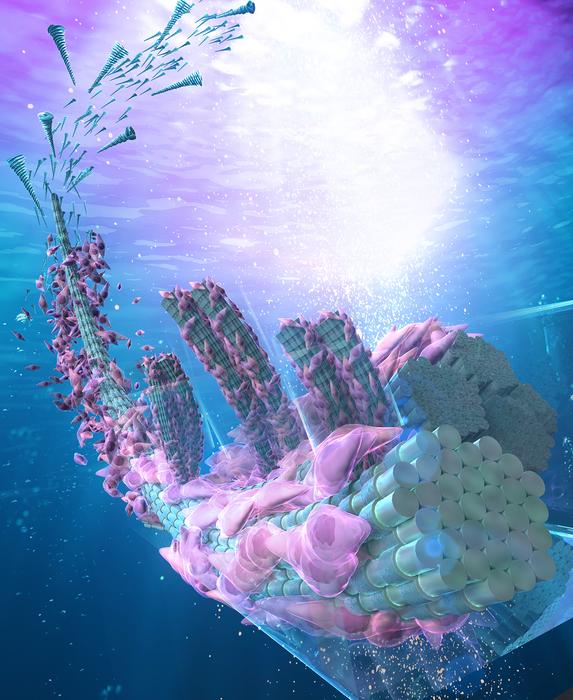

This technique fundamentally hinges on harnessing controlled fluid flow within the microchannels to direct fiber orientation. By carefully designing flow patterns through the fluidic device, the researchers induced collagen molecules and fibroblast cells to align along predetermined directions. Unlike previous orientation methods that typically produce unidirectional alignment, this system achieved precise multidirectional arrangement at a microscale level. The fluidic channels themselves act as versatile scaffolds, enabling the fabrication of tissue constructs with complex, biomimetic architectures closely resembling the interfibrillar arrangements in native tissues such as the dermal layer of skin or the compact bone’s lamellae.

From a materials science perspective, this advancement is significant because it offers a tunable, solvent-free method to manufacture hydrogels with hierarchical structural fidelity. The precise micro-orientation of collagen fibers is crucial, as it dictates the mechanical anisotropy that supports physiological functions such as load bearing, tensile strength, and cellular signaling. By guiding the fluid flow in multiple directions within a single construct, the researchers successfully engineered tissues with spatially varying fiber orientations—a biomimetic trait previously limited to natural tissues and challenging to replicate artificially.

Moreover, the use of 3D-printing technology to fabricate the master molds enables rapid prototyping and customization of channel geometries, paving the way for personalized tissue models. This feature is particularly promising for developing in vitro platforms that replicate patient-specific tissue microenvironments. Such platforms could revolutionize drug testing, disease modeling, and regenerative therapies by providing physiologically relevant scaffolds that closely emulate the anisotropic nature of human tissues.

The implications for translational medicine are substantial. As the orientation of collagen fibers profoundly impacts cell function—regulating behavior, differentiation, and extracellular matrix remodeling—engineered tissues that accurately reproduce these orientations have the potential to improve graft integration and functionality in vivo. For example, in skin grafts intended for burn victims or reconstructive surgeries, replicating the dermis’s multidirectional collagen fiber orientations could enhance mechanical durability and accelerate healing.

Kazutoshi Iijima, associate professor and one of the principal investigators of the study, explains that their fluidic alignment system offers a scalable and cost-effective alternative to existing fabrication methods. Without relying on volatile solvents or magnetic particles, the approach supports safer production standards suitable for clinical applications. “By manipulating flow channels constructed through 3D printing, we have demonstrated that simultaneously orienting collagen fibers and living cells in multiple directions is feasible—a breakthrough that closely mimics native tissue architectures,” he remarks.

This strategy’s ability to fine-tune fiber orientation extends beyond skin and bone tissue models. In principle, it can be adapted to a variety of biological tissues where anisotropic properties are crucial, such as cardiac muscle, tendons, and neural tissues. The researchers envision a future where customizable hydrogels serve as scaffolds for organoids or implantable constructs that can guide tissue regeneration with unprecedented precision.

Importantly, the study contributes to a deeper understanding of how biophysical cues generated by fluid flow influence cell alignment and extracellular matrix assembly. The dual role of the fluidic environment in simultaneously shaping collagen fibrils and orienting fibroblast cells hints at fundamental mechanobiological principles that govern tissue morphogenesis. This knowledge can inform the design of next-generation biomaterials capable of directing cell fate and improving therapeutic outcomes.

Further development of this platform includes exploring co-culture systems where multiple cell types interact within oriented hydrogels, thereby mimicking the cellular heterogeneity of native tissues. Additionally, integrating sensor technologies within the flow system could enable real-time monitoring of fiber alignment and cell behavior, facilitating adaptive fabrication processes.

As this technology matures, it promises to fortify the bridge between biomimetic tissue engineering and practical clinical applications. The use of fluidics and 3D printing to sculpt collagen hydrogels with multiscale, multidirectional orientation heralds a new era in fabricating tissue models that not only replicate biological form but also recapitulate function. This advancement aligns with the overarching goal of regenerative medicine: to restore damaged tissues with constructs indistinguishable from their natural counterparts, thereby enhancing patient outcomes and quality of life.

This groundbreaking research was published in the journal ACS Biomaterials Science and Engineering on May 12, 2025, and funded by the Japan Science and Technology Agency. The multidisciplinary team at YOKOHAMA National University, encompassing engineering science and biomedical faculties, spearheaded this innovative work that integrates principles from polymer chemistry, bioengineering, and cell biology. Their contributions underscore the growing convergence of applied sciences and life sciences in solving critical biotechnological challenges.

As the global scientific community continues to unravel collagen’s multifaceted roles and develop tools to manipulate its structure, this fluidic-oriented fabrication method stands out as a transformative platform. By combining the precision of microfluidics with the versatility of 3D printing, this approach marks a significant milestone in tissue engineering, setting the stage for futuristic therapies that harness the power of anisotropic biomaterials.

Subject of Research: Collagen fiber orientation, tissue engineering, fluidic alignment, 3D printed microfluidic devices, biomaterial scaffolds

Article Title: Fabrication of Multiscale, Multidirectional Orientated Collagen Hydrogels with Guided Cell Alignment Using Fluidics and a Three-Dimensional Printing

News Publication Date: 12-May-2025

Web References: https://pubs.acs.org/doi/10.1021/acsbiomaterials.4c02156

References: DOI: 10.1021/acsbiomaterials.4c02156

Image Credits: YOKOHAMA National University

Keywords

Collagen, Hydrogels, Tissue engineering, Tissue, Fibroblasts, Mesenchymal stem cells

Tags: 3D printing in tissue engineeringanisotropic mechanical properties of collagenbiocompatibility in collagen scaffoldsclinical applications of collagen hydrogelscollagen fiber orientation in tissuescollagen hydrogel fabricationfluid dynamics in tissue engineeringmulti-directionally oriented collagennovel approaches in regenerative medicineregenerative medicine innovationstraditional collagen orientation methodsYokohama National University research