In an impactful exploration of innovative fuel injection technology, researchers have turned their attention to high-pressure dual-injection (HPDI) systems, particularly those utilizing methanol as a fuel source for maritime applications. Recent studies highlight the importance of understanding nozzle behavior and fluid dynamics within these systems to enhance efficiency, minimize emissions, and accommodate the increasing demand for sustainable fuel alternatives in maritime transport. By integrating advanced optical spray investigations with three-dimensional computational fluid dynamics (3D-CFD) analyses, researchers have taken significant strides toward developing a greater understanding of the nozzle flow characteristics associated with methanol HPDI injectors.

At the core of this research is the methanol HPDI injector, a device that exemplifies the cutting-edge technology aimed at improving performance and reducing the environmental impact of maritime engines. Methanol stands out due to its renewability and potential for reducing greenhouse gas emissions when utilized in internal combustion engines. The ability of these injectors to precisely control the flow and atomization of fuel plays a pivotal role in achieving optimal combustion conditions, which directly reflect engine performance and exhaust composition.

The research team conducted extensive optical spray investigations to directly observe the fuel dynamics as it exits the nozzle. Utilizing high-speed cameras and advanced imaging techniques, they captured the intricate spray patterns and droplet sizes produced by the methanol injector. These visualizations are crucial, as the formation and distribution of the fuel spray significantly influence the combustion process within the engine cylinders. By analyzing these parameters, researchers aimed to pinpoint specific characteristics that contribute to enhanced fuel-air mixing and, consequently, improved combustion efficiency.

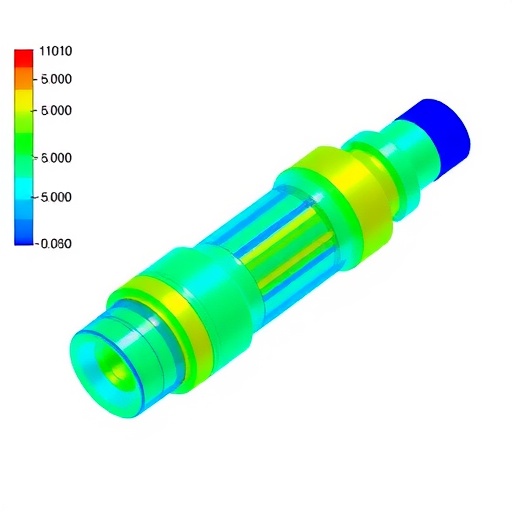

The implications of this research extend beyond mere observation; the findings are coupled with sophisticated 3D-CFD simulations that model the complex fluid dynamics at play. These simulations allow for a virtual environment wherein various operating conditions can be tested, revealing insights that are often difficult to glean from experimental setups alone. By inputting data from the optical investigations into the CFD models, researchers can refine their understanding of how nozzle design, spray characteristics, and operating conditions interplay to influence overall engine performance.

Furthermore, the choice of methanol as a fuel source is more than a matter of efficiency; it is a conscious decision aiming to address environmental concerns associated with traditional marine fuels. As global regulations become increasingly stringent regarding emissions from ships, the maritime industry faces pressing challenges. Innovating fuel injection systems that can effectively utilize cleaner fuels like methanol is essential for enabling compliance with these regulations while still meeting the operational demands of the industry.

One of the significant advantages of methanol is its versatility. The fuel can be produced from various renewable sources, including biomass, which opens doors to a cradle-to-grave sustainable lifecycle. This research on the HPDI injector showcases not only technological advancements but also a broader commitment to sustainability within maritime operations. The integration of renewable fuels into existing systems represents a critical step toward decarbonizing maritime transport and reducing dependency on fossil fuels.

In addition to focusing on performance metrics, this research encourages discussion about the future landscape of marine propulsion systems. Enhanced fuel flexibility and better combustion efficiency can lead to unprecedented operational savings for ship operators, making investments in modern fuel injector technologies a wise financial decision in addition to environmental responsibility. The navigation towards sustainable maritime operations is not merely aspirational; it is becoming an economic imperative for stakeholders in the industry.

As data from optical investigations and CFD analysis is meticulously compiled, the researchers are also preparing to present their findings to the academic and industrial communities. The expected outcomes include recommendations for nozzle design improvements, operational adjustments, and insights that may guide future research efforts in the domain of HPDI technology. By fostering collaboration between academia and industry, the researchers hope their findings will catalyze further innovations in fuel injection systems.

In conclusion, the optical spray investigations and CFD analyses of the methanol HPDI injectors present a promising direction for the future of maritime fuel technologies. As the industry grapples with the dual challenges of efficiency and environmental impact, findings from this research could serve as a blueprint for next-generation fuel systems that prioritize sustainability without compromising on performance. The transformation of maritime fuel injection technology is not just an engineering challenge; it reflects the larger narrative of our collective effort toward a more sustainable future.

The ramifications of this research extend beyond the world of academia and engineering. As the findings are integrated into commercial applications, they could stimulate a response from policymakers and regulators, potentially leading to increased support for alternative fuels and advanced engine technologies. Thus, it participates in a crucial dialogue around energy policy, climate action, and the future of global trade that heavily relies on maritime transport.

By embracing these innovative technologies, stakeholders in maritime logistics can gain a competitive edge in a rapidly evolving global marketplace. The dawn of more efficient, cleaner maritime engines signifies perhaps the most crucial step forward in our journey toward a sustainable future. Methanol HPDI injectors could very well be a cornerstone of this transition, encouraging further research and investment and ultimately leading to the greener shores of global shipping.

Subject of Research: Methanol HPDI injectors for maritime applications

Article Title: Optical spray investigations and 3D-CFD numerical analysis of the nozzle flow of a methanol HPDI injector for maritime applications.

Article References:

Rektorik, P., Schmid, F., Wloka, J. et al. Optical spray investigations and 3D-CFD numerical analysis of the nozzle flow of a methanol HPDI injector for maritime applications. Automot. Engine Technol. 8, 193–209 (2023). https://doi.org/10.1007/s41104-023-00135-x

Image Credits: AI Generated

DOI: 10.1007/s41104-023-00135-x

Keywords: Methanol, HPDI injectors, maritime applications, fuel efficiency, emissions reduction, combustion technology, CFD simulations, optical investigations, sustainable fuel, marine propulsion systems.

Tags: 3D-CFD analysis of fuel injectionadvanced optical spray investigationscombustion performance optimizationenvironmental impact of maritime transportfluid dynamics in engineshigh-pressure dual-injection systemsinnovative fuel injection systemsmaritime fuel efficiencymethanol HPDI injector technologynozzle flow characteristicsreducing greenhouse gas emissionssustainable fuel alternatives