Credit: Polytechnique Montréal

Carbon nanotubes have made headlines in scientific journals for a long time, as has 3D printing. But when both combine with the right polymer, in this case a thermoplastic, something special occurs: electrical conductivity increases and makes it possible to monitor liquids in real time. This is a huge success for Polytechnique Montréal.

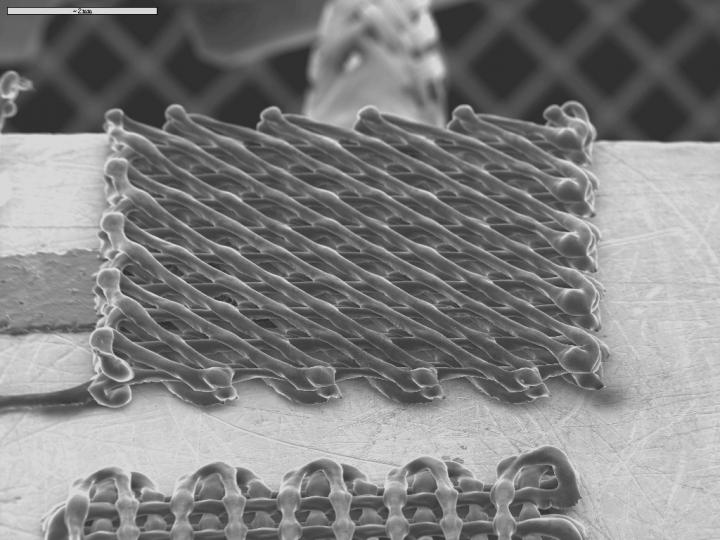

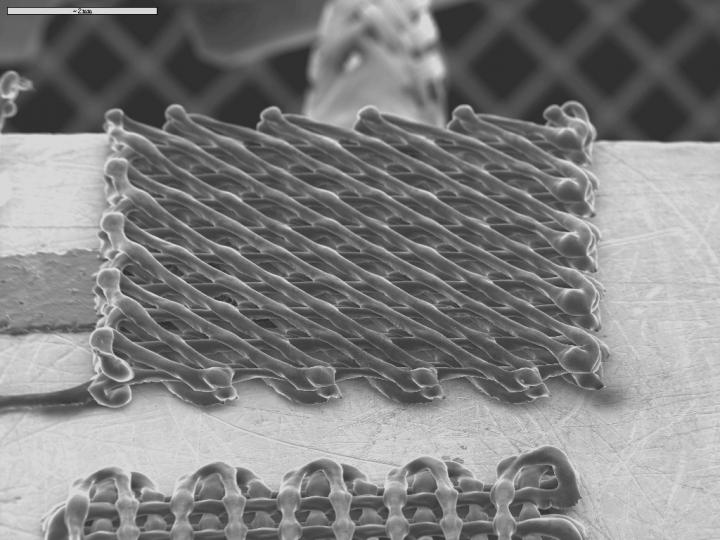

The article "3D Printing of Highly Conductive Nanocomposites for the Functional Optimization of Liquid Sensors" was published in the journal Small. Renowned in the field of micro- and nanotechnology, Small placed this article on its back cover, a sure sign of the relevance of the research conducted by mechanical engineer Professor Daniel Therriault and his team. In practical terms, the result of this research looks like a cloth; but as soon as a liquid comes into contact with it, said cloth is able to identify its nature. In this case, it is ethanol, but it might have been another liquid. Such a process would be a terrific advantage to heavy industry, which uses countless toxic liquids.

A simple yet efficient recipe

While deceptively simple, the recipe is so efficient that Professor Therriault protected it with a patent. In fact, a U.S. company is already looking at commercializing this material printable in 3D, which is highly conductive and has various potential applications.

The first step: take a thermoplastic and, with a solvent, transform it into a solution so that it becomes a liquid. Second step: as a result of the porousness of this thermoplastic solution, carbon nanotubes can be incorporated into it like never before, somewhat like adding sugar into a cake mix. The result: a kind of black ink that's fairly viscous and whose very high conductivity approximates that of some metals. Third step: this black ink, which is in fact a nanocomposite, can now move on to 3D printing. As soon as it comes out of the printing nozzle, the solvent evaporates and the ink solidifies. It takes the form of filaments slightly bigger than a hair. The manufacturing work can then begin.

The advantages of this technology

The research conducted at Polytechnique Montréal is at the vanguard in the field of uses for 3D printers. The era of amateurish prototyping, like printing little plastic objects, belongs to the past. These days, all manufacturing industries, whether aviation, aerospace, robotics or medicine, etc., have set their sights on this technology.

There are several reasons for this. Firstly, the lightness of parts because plastic is substituted for metal. Then there is the precision of the work done at the microscopic level, as is the case here. Lastly, with the nanocomposite filaments usable at room temperature, conductivities can be obtained that approximate those of some metals. Better still, since the geometry of filaments can be varied, measures can be calibrated that make it possible to read the various electric signatures of liquids that are to be monitored.

A topical example: pipelines

At the connection points of pipes that form pipelines, there are flanges. The idea would be to factory- manufacture the pipes with flanges coated by 3D printing. The coating would be a nanocomposite whose electric signature is calibrated according to the liquid being transported – oil, for instance. If there is a leak and the liquid touches the printed sensors based on the concept developed by Professor Therriault and his team, an alert would sound in record time, and in a very targeted way. That's a tremendous advantage, both for the population and the environment; in case of a leak, the faster the reaction time, the lesser the damages.

###

Professor Therriault's work received support from the Centre de recherche sur les systèmes polymères et composites à haute performance (Research Centre for High-Performance Polymer and Composite Systems – CREPEC), the Canada Research Chairs, the Natural Sciences and Engineering Research Council of Canada (NSERC), Mitacs and the Canada Foundation for Innovation (CFI).

Chizari, K., Daoud, M.A., Ravindran, A.R., & Therriault, D. (2016). Liquid Materials: 3D Printing of Highly Conductive Nanocomposites for the Functional Optimization of Liquid Sensors (Small 44/2016). Small, 12(44), 6176-6176.

doi: 10.1002/smll.201670232

About Polytechnique Montréal

Founded in 1873, Polytechnique Montréal is one of Canada's leading engineering teaching and research institutions. It is the largest engineering university in Québec for the size of its graduate student body and the scope of its research activities. With over 45,700 graduates, Polytechnique Montréal has educated nearly one-quarter of the current members of the Ordre des ingénieurs du Québec. The institution offers more than 120 programs. Polytechnique has 250 professors and over 8,200 students. It has an annual operating budget of more than $210 million, including a research budget exceeding $70 million.

Media Contact

Annie Touchette

[email protected]

514-231-8133

@polymtl

http://www.polymtl.ca

############

Story Source: Materials provided by Scienmag